An intelligent pressing device for dust-proof and noise-reducing motor processing

A compression device and noise-reducing technology, which is applied in the field of intelligent compression devices, can solve problems such as the increase in the processing time of the motor shell, the reduction in the processing efficiency of the motor, and the cumbersome calibration of the motor, so as to reduce the reduction in processing efficiency and reduce the processing efficiency. Improve the effect of safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

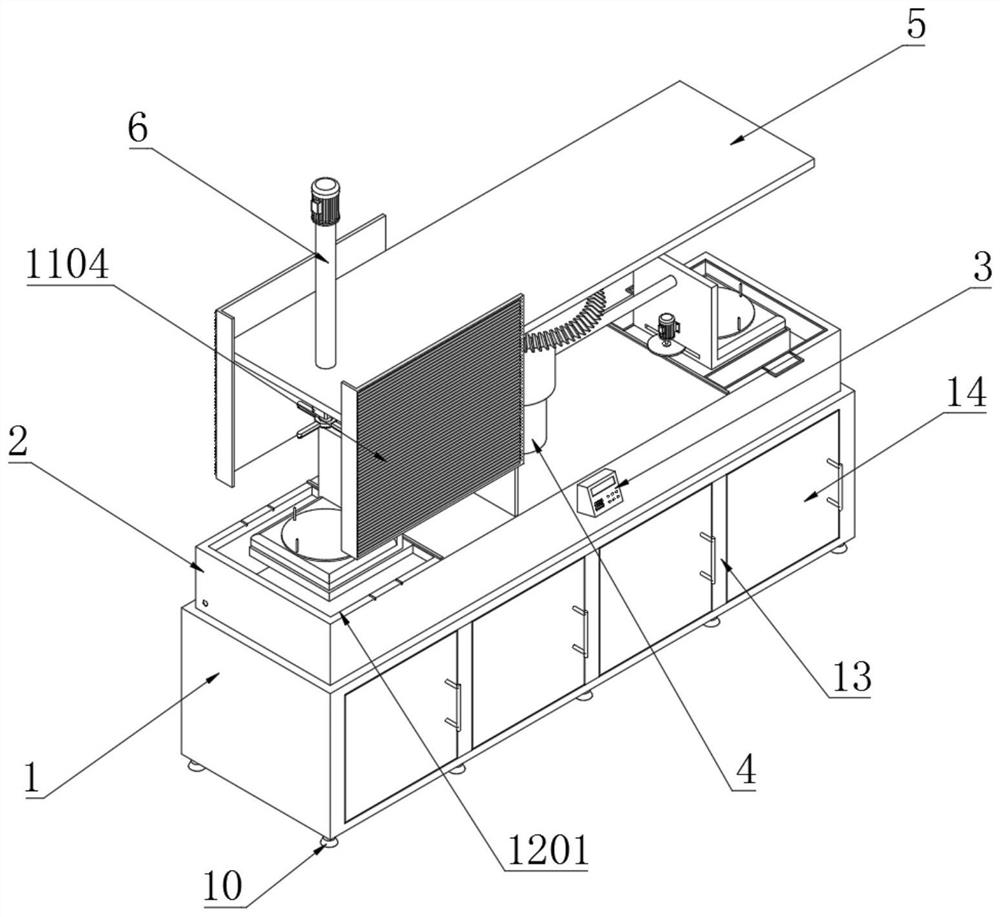

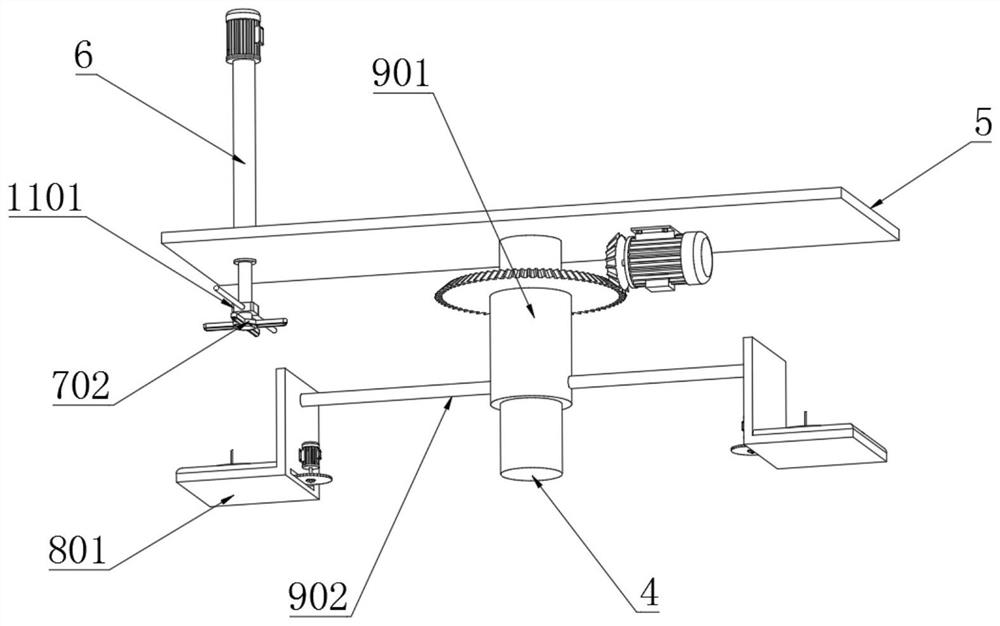

[0057] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, an intelligent pressing device for dust-proof and noise-reducing motor processing, including:

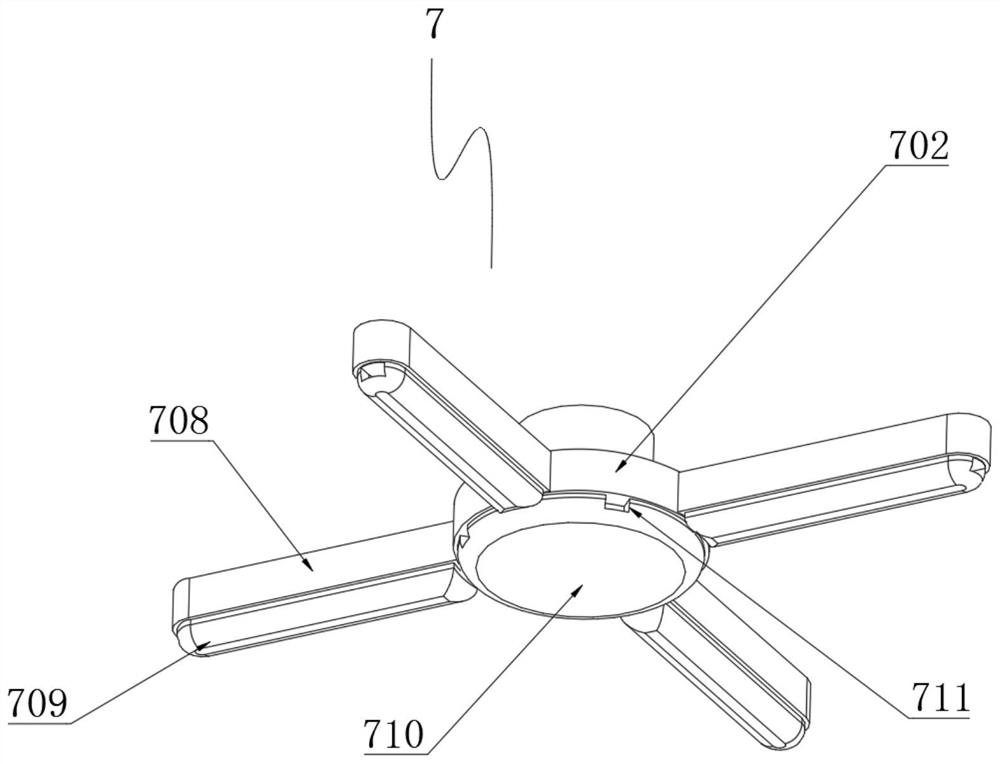

[0058] The pressing component 7 is installed on the bottom end of the electro-hydraulic push rod 6, and is used for processing the motor shell to compress the motor shell, and assists the rotation with the rotation of the motor shell;

[0059] The loading and unloading component 8 is used for loading and unloading the motor housing and rotating the motor housing, and processing different surfaces of the motor housing;

[0060] The refueling assembly 9 is used to quickly replace the loading assembly 8 under the pressing assembly 7, remove the processed motor housing and provide a new motor housing for processing;

[0061] The noise reduction component 11 is used for the processing of the motor shell. With the electrohydraulic push rod 6, the push rod is pressed down, and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com