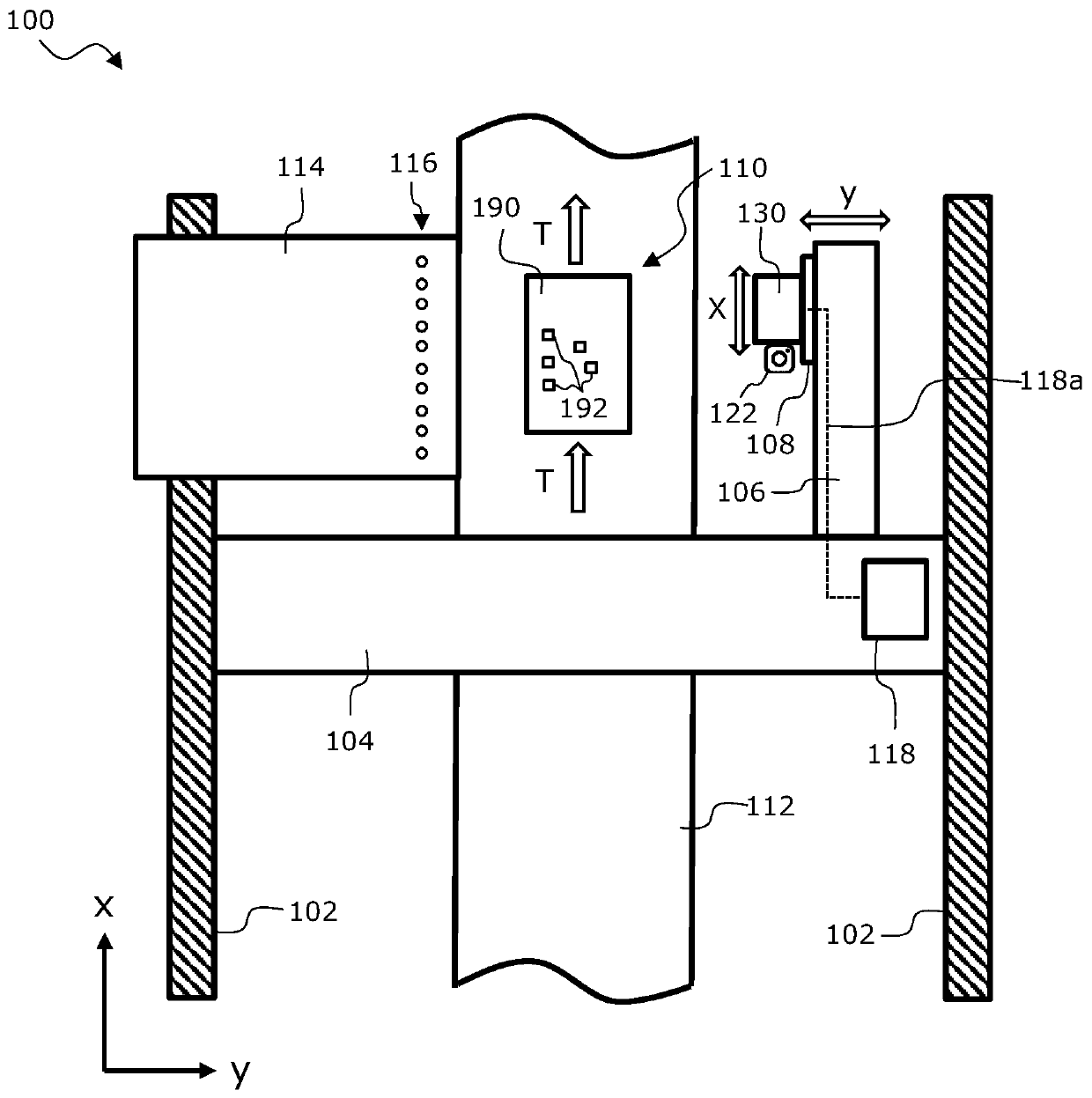

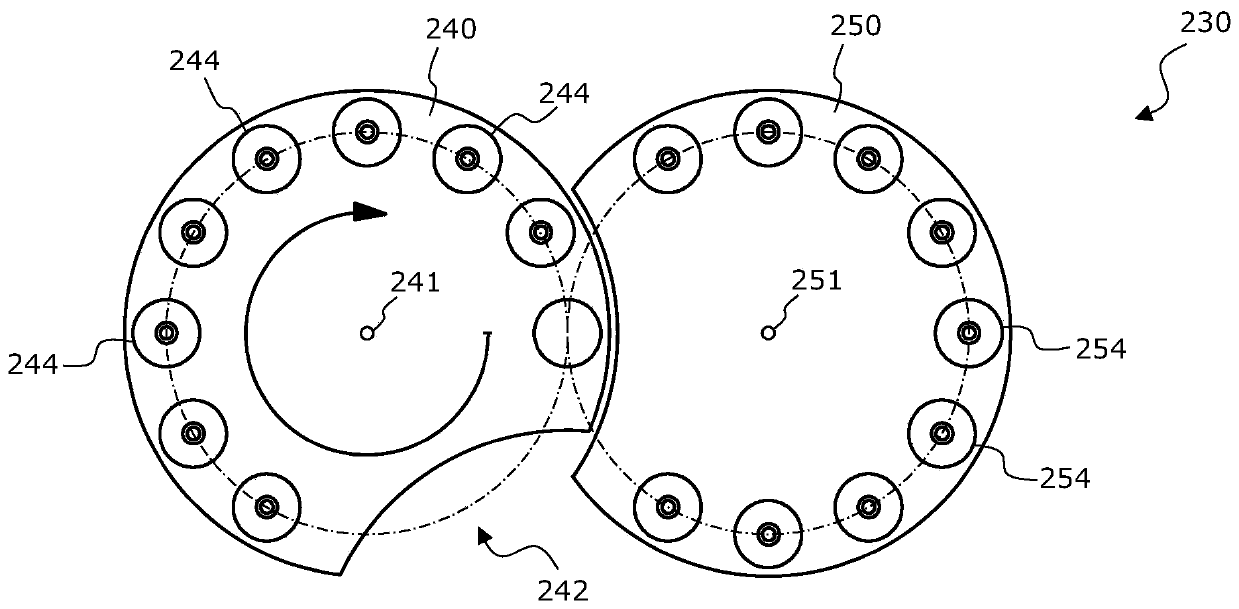

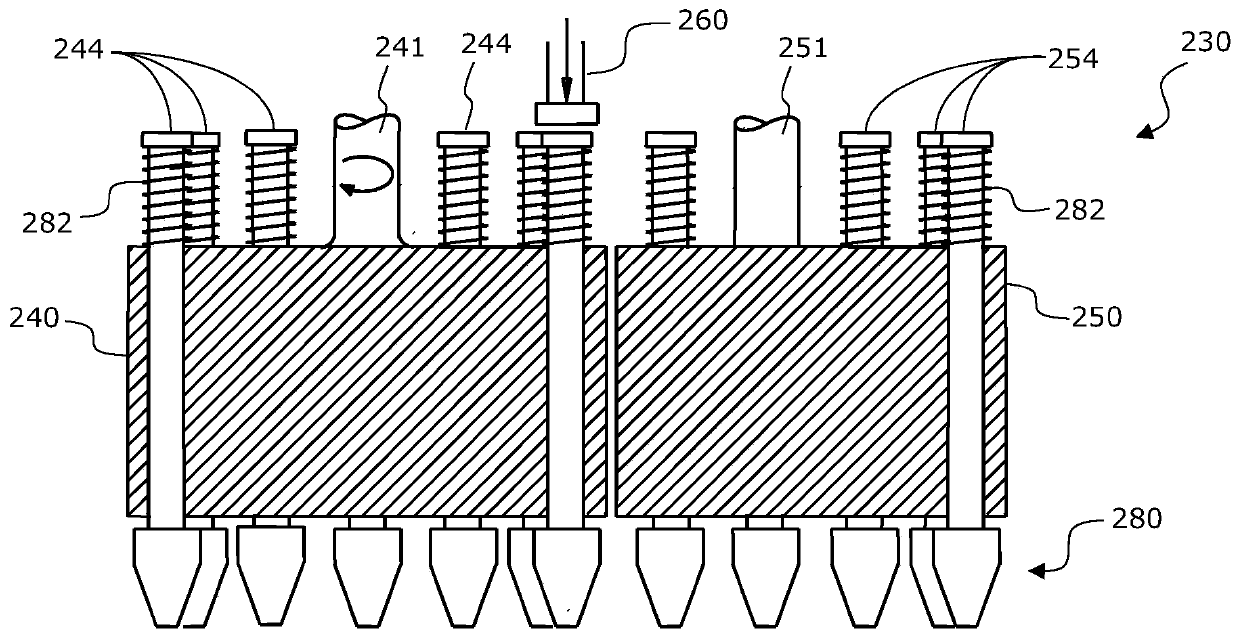

An assembly head having mutually engaged rotors

A technology for assembling heads and rotors, applied in the direction of electrical components, electrical components, etc., can solve the problems of assembly machine speed and precision assembly head quality limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] It should be noted that in the following detailed description, features or components of different embodiments (which are the same or at least functionally identical to corresponding features or components of other embodiments) are marked with the same reference numerals or different reference numerals, and these different The reference numerals of are identical in the last two letters to the reference numerals of identical or at least functionally identical features or components. In order to avoid unnecessary repetition, features or components which have already been explained with reference to the exemplary embodiments described above will not be explained in more detail below.

[0083] Furthermore, it should be pointed out that the embodiments described below represent only a limited selection of possible variants of the invention. In particular, it is possible to combine features of the individual embodiments with one another in a suitable manner, so that many diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com