Smoked mung bean curd and manufacturing process thereof

A production process, mung bean technology, applied in the field of fragrant dried, can solve the problems of too soft or too hard taste, single taste, not fresh enough, etc., and achieve the effect of long storage time, delicious taste and fragrant aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A fragrant dried mung bean, the formula comprising: soybeans, mung beans and enzymes, the parts by weight of each component are: 1200 parts of soybeans, 400 parts of mung beans and 8 parts of enzymes.

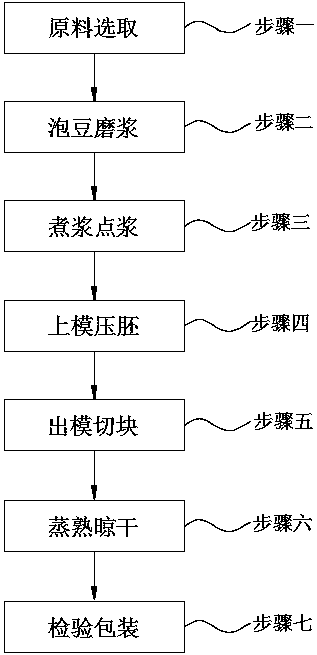

[0026] A manufacturing process of dried mung beans, comprising the following steps: Step 1, raw material selection; Step 2, soaking soybeans and grinding; Step 3, boiling the pulp and ordering pulp; Step 4, pressing the embryo on the upper mold; Step 5, cutting out the mold; Six: Steam and dry; Step seven, check the packaging;

[0027] Wherein in above-mentioned step 1, according to the weight percent content of each component is respectively: the soybean of 1200 parts, the mung bean of 400 parts and the ferment of 8 parts are selected;

[0028] Wherein in the above-mentioned step 2, soaking soybean defibrination comprises the following steps:

[0029] 1) Wash and soak the selected soybeans and mung beans. The amount of water should cover the soybeans and mung beans. Th...

Embodiment 2

[0038] A fragrant dried mung bean, the formula comprising: soybeans, mung beans and enzymes, the parts by weight of each component are: 1250 parts of soybeans, 350 parts of mung beans and 8 parts of enzymes.

[0039] A manufacturing process of dried mung beans, comprising the following steps: Step 1, raw material selection; Step 2, soaking soybeans and grinding; Step 3, boiling the pulp and ordering pulp; Step 4, pressing the embryo on the upper mold; Step 5, cutting out the mold; Six: Steam and dry; Step seven, check the packaging;

[0040] Wherein in above-mentioned step 1, according to the weight percent content of each component is respectively: the soybean of 1250 parts, the mung bean of 350 parts and the ferment of 8 parts are selected;

[0041] Wherein in the above-mentioned step 2, soaking soybean defibrination comprises the following steps:

[0042] 1) Wash and soak the selected soybeans and mung beans. The amount of water should cover the soybeans and mung beans. Th...

Embodiment 3

[0051] A kind of mung bean fragrant dry, formula comprises: soybean, mung bean and ferment, and the parts by weight of each component are respectively: 1300 parts of soya bean, 400 parts of mung bean and 8 parts of ferment.

[0052] A manufacturing process of dried mung beans, comprising the following steps: Step 1, raw material selection; Step 2, soaking soybeans and grinding; Step 3, boiling the pulp and ordering pulp; Step 4, pressing the embryo on the upper mold; Step 5, cutting out the mold; Six: Steam and dry; Step seven, check the packaging;

[0053] Wherein in above-mentioned step 1, according to the weight percent content of each component is respectively: the soybean of 1300 parts, the mung bean of 400 parts and the ferment of 8 parts are selected;

[0054] Wherein in the above-mentioned step 2, soaking soybean defibrination comprises the following steps:

[0055] 1) Wash and soak the selected soybeans and mung beans. The amount of water should cover the soybeans an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com