Frequency self-adaptive microporous atomizing element and preparation method thereof

A frequency-adaptive, micro-porous atomization technology, applied in spray devices, liquid spray devices, etc., can solve problems such as inconvenient matching, and achieve the effect of simplifying matching, eliminating selectivity and dependence, and improving the effect of on-machine atomization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments to be described below will refer to the corresponding drawings, which constitute a part of the embodiments, and describe the embodiments used to realize the present invention. It is to be understood that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the present invention.

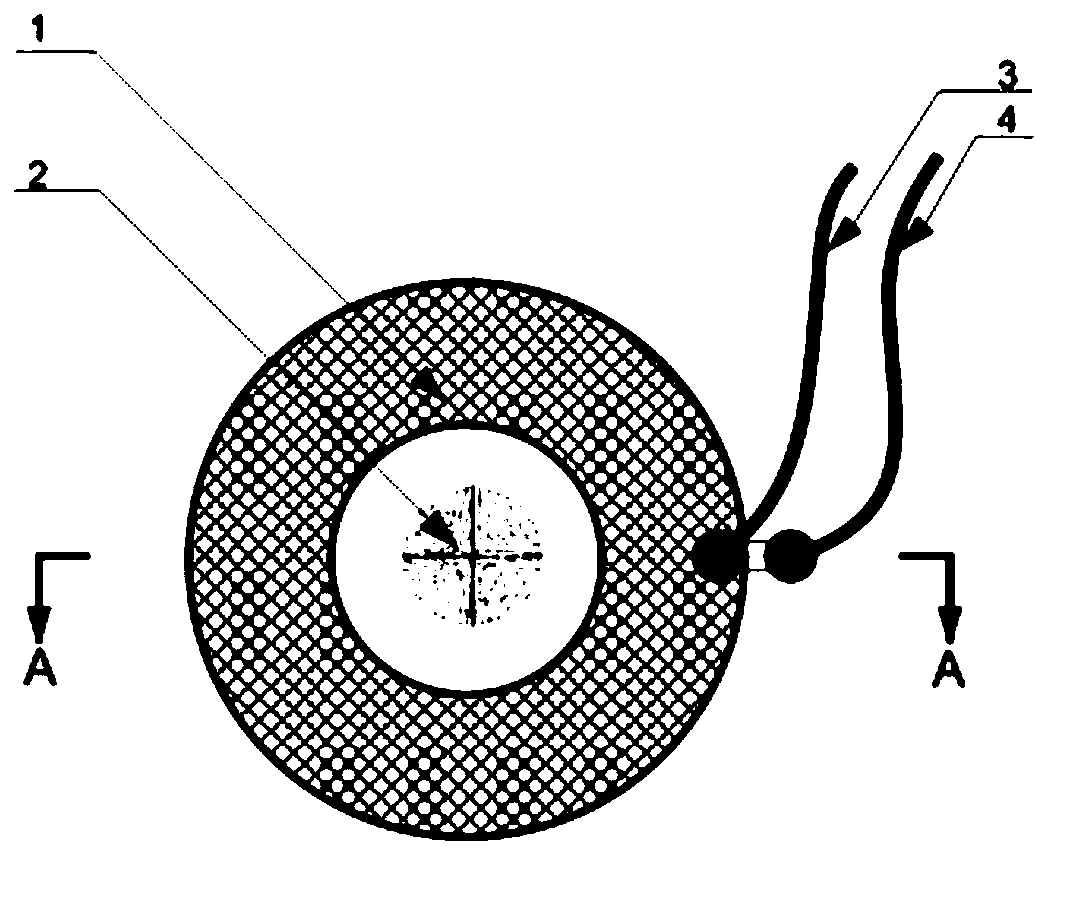

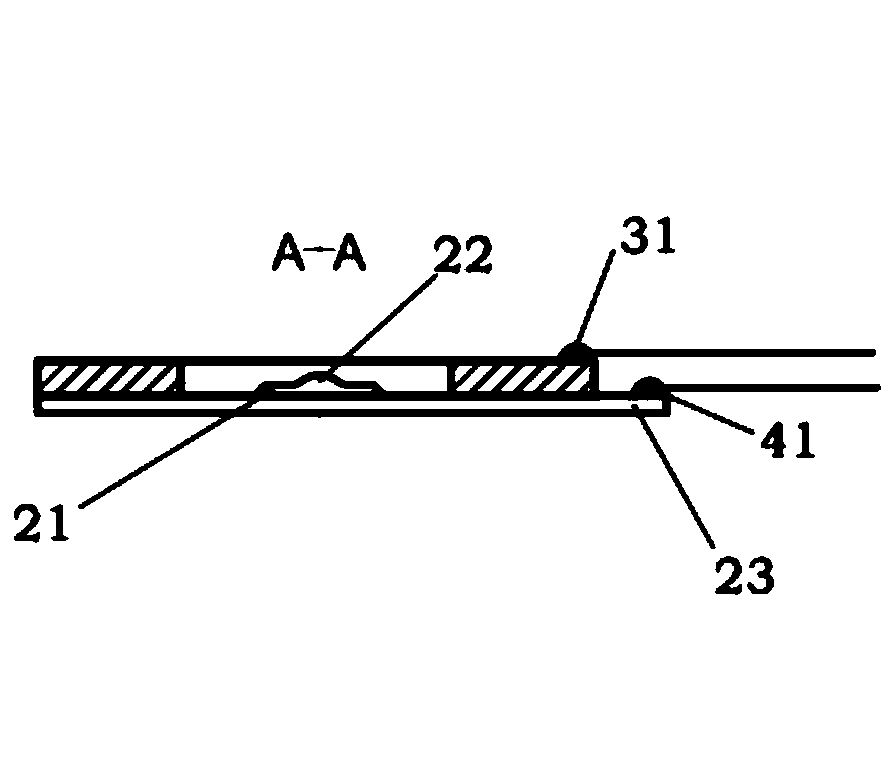

[0025] An embodiment of the present invention, such as figure 1 As shown, a frequency-adaptive microporous atomization element includes a ring-shaped piezoelectric ceramic sheet 1 and a metal substrate 2 attached to the opposite side of the ring-shaped piezoelectric ceramic sheet. The middle area of the metal substrate 1 is provided with a Microporous area, according to figure 2 As shown in the A-A sectional view, it can be seen that the micropore area is a rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com