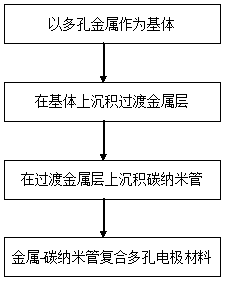

A kind of preparation method of metal-carbon nanotube composite porous electrode material

A carbon nanotube composite, porous electrode technology, applied in electrode manufacturing, hybrid/electric double layer capacitor manufacturing, battery electrodes, etc., can solve the problem of poor uniformity and consistency of carbon nanotubes, disordered surface orientation, and disordered pores order and other problems, to achieve uniform and orderly distribution of pipe diameter and length, improve performance and service life, and reduce the phenomenon of agglomeration and agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Using nickel foam as the substrate, the selected nickel foam has an average pore diameter of 100 μm and a thickness of 0.3 mm. Ni is deposited on the surface of the substrate as a transition metal layer using vacuum magnetron sputtering technology. The working parameters are: vacuum chamber background vacuum ≤ 5×10 -2 Pa, the pressure in the vacuum chamber during sputtering coating is ≤1Pa, the target power density applied per decimeter of target width is 0.1 kW to 1 kW, and the average thickness of the transition metal layer is 5 nm. In the vacuum furnace chamber, evacuate until the background vacuum inside the furnace chamber is ≤2 Pa, and then raise the temperature to 700 °C. During the heating process, argon gas is introduced as a protective gas. When the set temperature is reached, ethane gas is introduced. The volume ratio of gas to argon is 1:5, the reaction ends after 20 minutes, stop feeding ethane gas, and cool to room temperature under the protection of argon...

Embodiment 2

[0024] With aluminum foam as the substrate, the selected aluminum foam has an average pore diameter of 500 μm and a thickness of 1.5 mm. Co is deposited on the surface of the substrate as a transition metal layer using vacuum magnetron sputtering technology. The working parameters are: vacuum chamber background vacuum ≤ 5×10 -2 Pa, the pressure in the vacuum chamber during sputtering coating is ≤1Pa, the target power density applied per decimeter target width is 0.1 kW to 1 kW, and the average thickness of the transition metal layer is 350 nm. In the vacuum furnace cavity, vacuumize until the background vacuum inside the furnace cavity is ≤ 2 Pa, and then raise the temperature to 800 ° C. During the heating process, argon gas is introduced as a protective gas. When the set temperature is reached, methane gas is introduced. The methane gas and The volume ratio of argon is 1:2, and the reaction ends after 30 minutes. Stop feeding methane gas and cool to room temperature under th...

Embodiment 3

[0026] With nickel-iron foam as the substrate, the selected nickel-iron foam has an average pore diameter of 600 μm and a thickness of 2.5 mm. Ni-Co alloy is deposited on the surface of the substrate as a transition metal layer using vacuum magnetron sputtering technology. The working parameters are: vacuum Cavity background vacuum ≤5×10 -2 Pa, the pressure in the vacuum chamber during sputtering coating is ≤1Pa, the target power density applied per decimeter target width is 0.1 kW to 1 kW, the average thickness of the transition metal layer is 400 nm, and the Ni-Co alloy will be deposited on the surface Foam nickel-iron is placed in the vacuum furnace cavity, vacuumed until the background vacuum inside the furnace cavity is ≤2 Pa, and then heated up to 700 ℃, argon gas is introduced as a protective gas during the heating process, and ethylene gas is injected when the set temperature is reached , the volume ratio of ethylene gas to argon gas is 1:2, the reaction ends after 45 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com