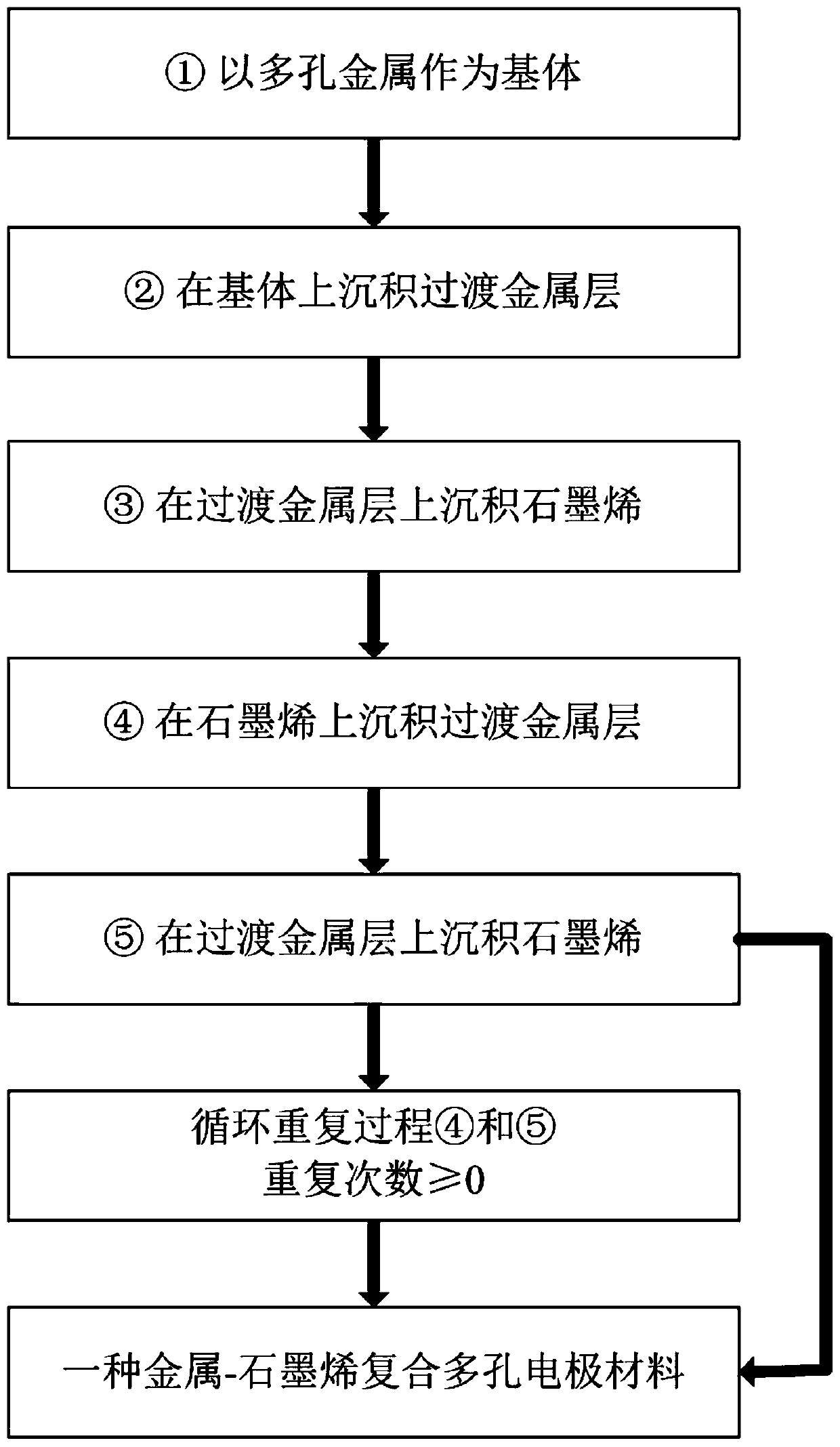

A kind of preparation method of metal-graphene composite porous electrode material

A graphene composite and porous electrode technology, which is applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problems of increasing nucleation density, difficulty in controlling, and uneven number of layers, etc. The effect of large electrode surface area, improved coverage, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using nickel foam as the substrate, the selected nickel foam has an average pore diameter of 100 μm and a thickness of 0.3 mm. Cu is deposited on the surface of the substrate as a transition metal layer using vacuum magnetron sputtering technology. The working parameters are: vacuum chamber background vacuum ≤ 5×10 -2 Pa, the pressure in the vacuum chamber during sputtering coating is ≤1Pa, the target power density applied per decimeter target width is 0.1 kW to 1 kW, and the average thickness of the transition metal layer is 5 nm; the nickel foam deposited on the surface of Cu is placed In the vacuum furnace chamber, evacuate until the background vacuum inside the furnace chamber is ≤2 Pa, then raise the temperature to 900 °C, and at the same time pass in the mixed gas of hydrogen and argon, keep it warm for 15 minutes, continue to heat up to 1040 °C, and then pass in methane Gas for reaction, the reaction time is 0.5 minutes, stop feeding methane gas after the reactio...

Embodiment 2

[0027] Using foamed aluminum as the substrate, the selected foamed aluminum has an average pore diameter of 500 μm and a thickness of 1.5 mm; use vacuum magnetron sputtering technology to deposit Cu-Ni alloy on the surface of the substrate as a transition metal layer, and its working parameters are: vacuum chamber Bottom vacuum≤5×10 -2Pa, the pressure in the vacuum chamber during sputtering coating is ≤1Pa, the target power density applied per decimeter target width is 0.1 kW to 1 kW, and the average thickness of the transition metal layer is 300 nm; the Cu-Ni alloy will be deposited on the surface Put the aluminum foam in the vacuum furnace chamber, evacuate until the background vacuum inside the furnace chamber is ≤2 Pa, then raise the temperature to 800 °C, and at the same time pass in the mixed gas of hydrogen and argon, keep it warm for 20 minutes, continue to heat up to 1000 °C, and then The toluene gas was introduced to react, and the reaction time was 5 minutes. After ...

Embodiment 3

[0029] With nickel-iron foam as the substrate, the selected foamed nickel-iron has an average pore diameter of 400 μm and a thickness of 1.8 mm; use vacuum magnetron sputtering technology to deposit Co-Ni alloy on the surface of the substrate as a transition metal layer, and its working parameters are: vacuum Cavity background vacuum ≤5×10 -2 Pa, the pressure in the vacuum chamber during sputtering coating is ≤1Pa, the target power density applied per decimeter target width is 0.1 kW to 1 kW, and the average thickness of the transition metal layer is 400 nm; the Co-Ni alloy will be deposited on the surface Foam nickel-iron is placed in the vacuum furnace cavity, evacuated until the background vacuum inside the furnace cavity is ≤2 Pa, and then the temperature is raised to 750 °C, and the mixed gas of hydrogen and argon is introduced at the same time, and the temperature is kept for 30 minutes, and the temperature is continued to rise to 975 °C. Then feed ethane gas to react, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com