Indirect additive manufacturing equipment and additive manufacturing method thereof

An additive manufacturing and equipment technology, applied in the field of forming equipment, to achieve the effect of reducing production costs, avoiding environmental pollution, and shortening the degreasing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and specific embodiments.

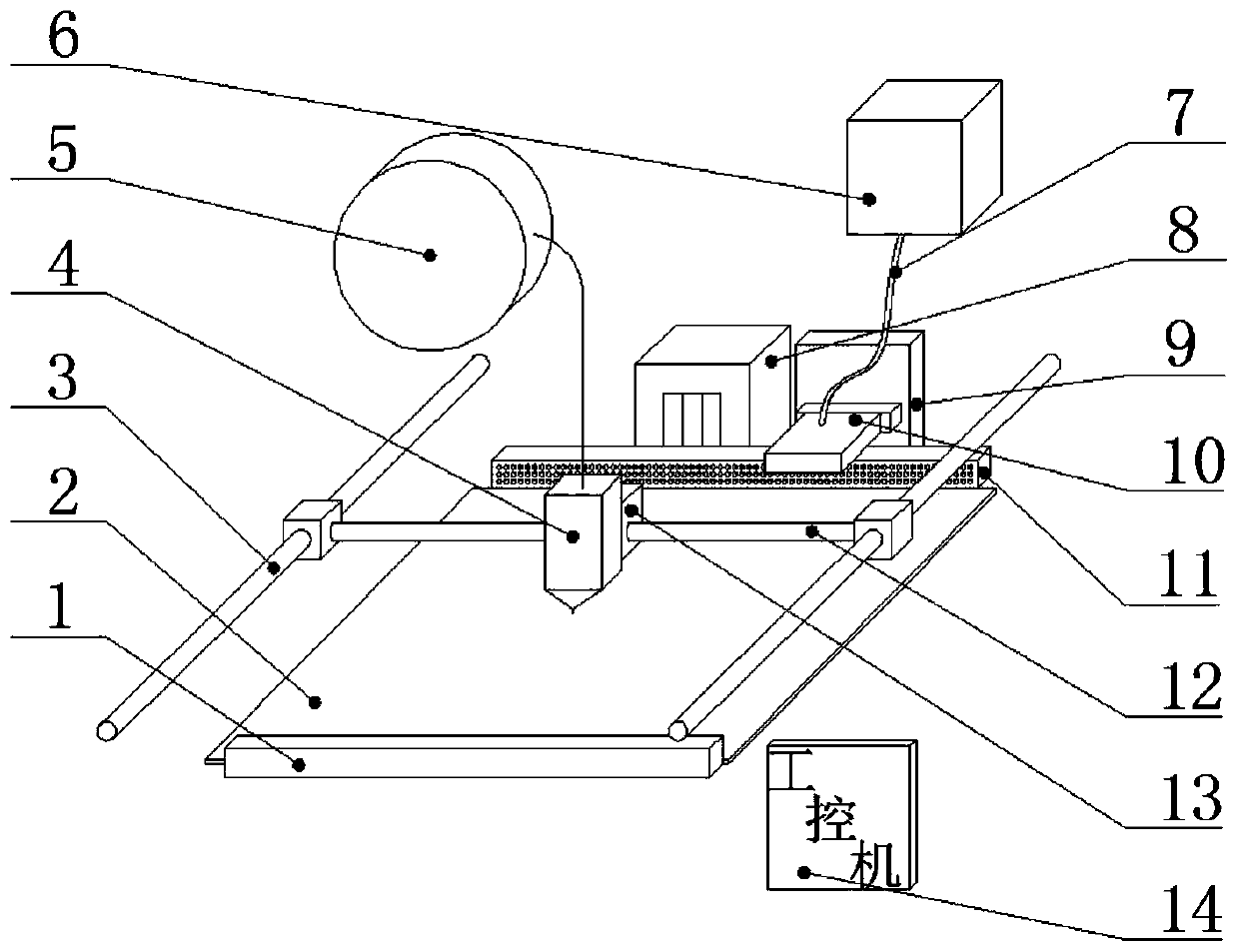

[0024] The present invention is an indirect additive manufacturing equipment, such as figure 1 As shown, an indirect additive manufacturing equipment includes an extrusion mechanism 4, the extrusion mechanism 4 is a melting nozzle, the extrusion mechanism 4 is connected with a feeding system 5, and also includes a Z that drives the part pallet 2 to move along the Z axis. Shaft mechanism 8, the parts support plate 2 is connected to the side of the Z-axis mechanism 8; it also includes a nozzle array 10, which is connected to a catalyst reservoir 6 through a control line 7; it also includes a moving rail, a nozzle array 10 and an extrusion mechanism 4 are compatible with the motion guide; a part support plate 2 is provided under the motion guide, and a grease collection system is provided on the part support plate 2;

[0025] An industrial computer 14 is also incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com