Fuel injection device for internal combustion engine

A technology of fuel injection device and internal combustion engine, which is applied in the directions of fuel injection device, fuel injection device with oil accumulator, charging system, etc., can solve complex and expensive problems and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

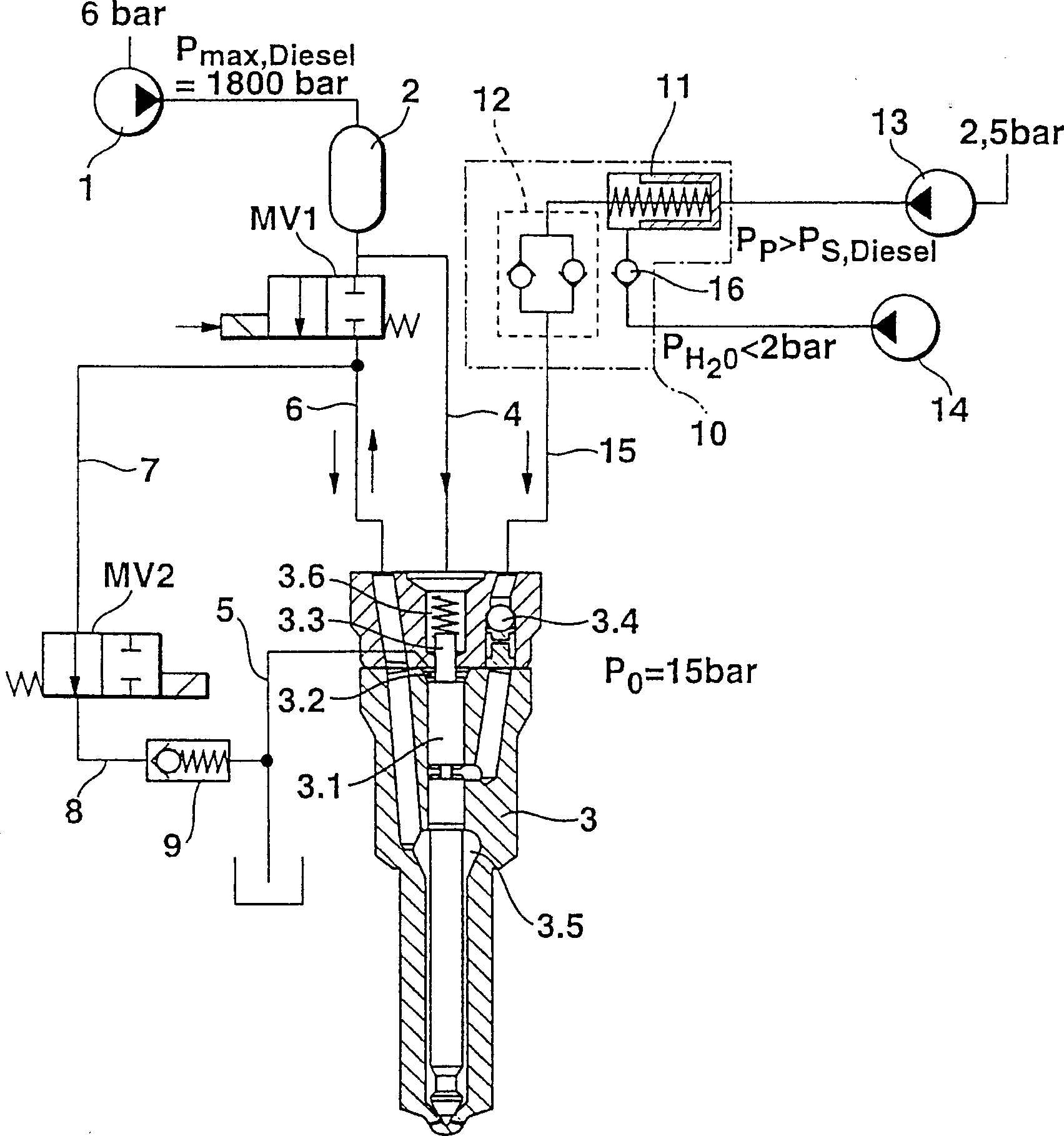

[0023] exist figure 1 A first embodiment of a fuel injection device for an internal combustion engine according to the invention is shown in the table for the injection of two liquids, namely fuel (usually diesel) and an additive fluid (usually water), wherein a high-pressure The pump 1 supplies a common rail pressure accumulator (Common-Rail-Druckspeicher) 2 with fuel at a pressure value of about 1800 bar. Between the common rail pressure accumulator 2 and a pressure chamber 3.5 fed by it via a fuel injection line 6, a quantitative component must then be provided, wherein the pressure chamber 3.5 surrounds the fuel injection needle 3.1 of a two-material nozzle 3, Because the conventional jet pump in the past will be replaced by the combination of the common rail pressure accumulator 2 and the simple pressure pump 1, and the pressure of the accumulator pipe should have a certain value continuously. This task is performed by the first 2 / 2-way valve MV1 in the device according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com