Building steel bar rust remover

A technology for building steel bars and derusting machines, which is applied to the parts of grinding machine tools, grinding machines, grinding/polishing equipment, etc. It can solve the problems of difficult work, spraying rust removers to the edges of steel bars, troublesome operation, etc., to achieve The effect of reducing work difficulty, simple operation and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

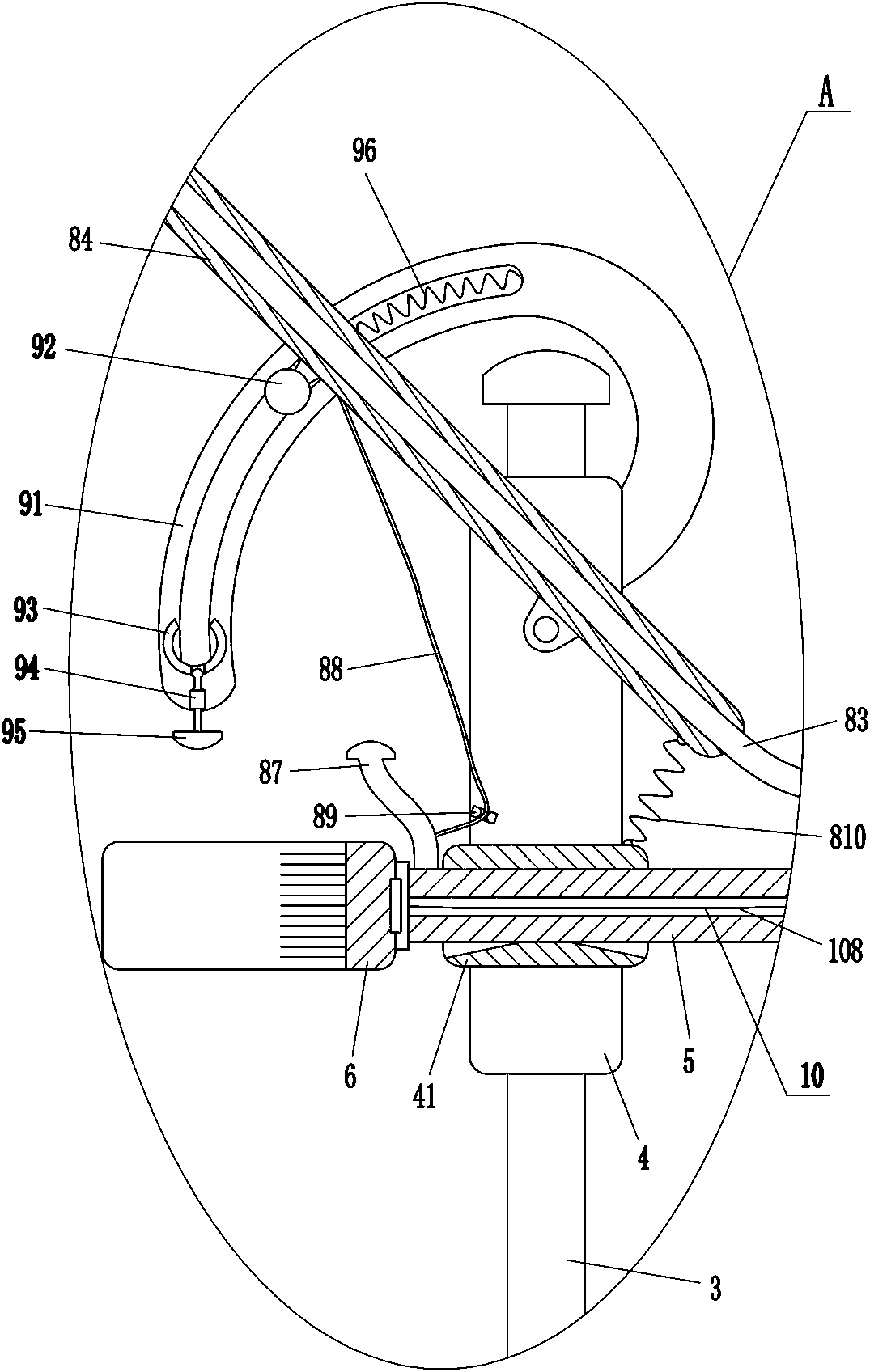

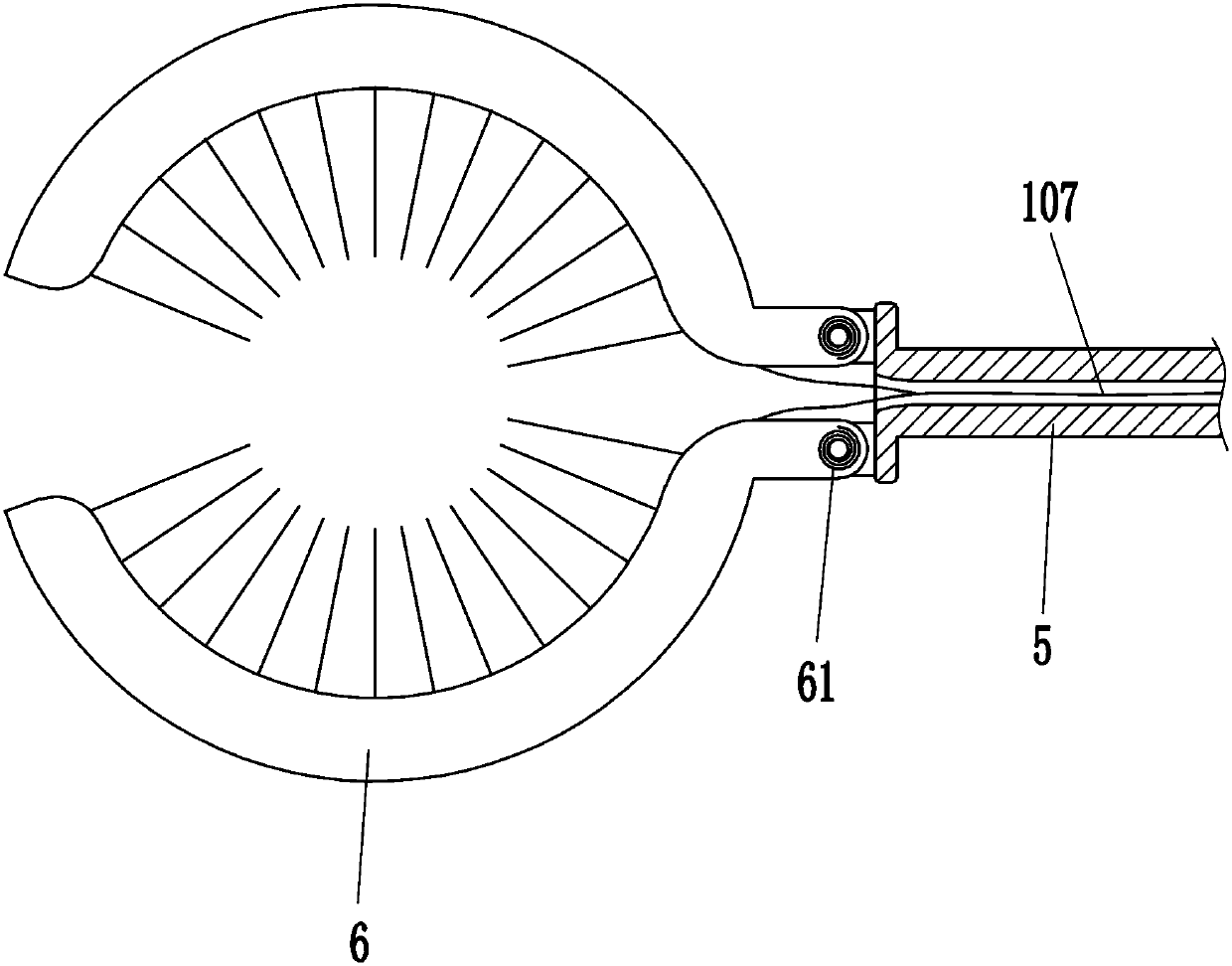

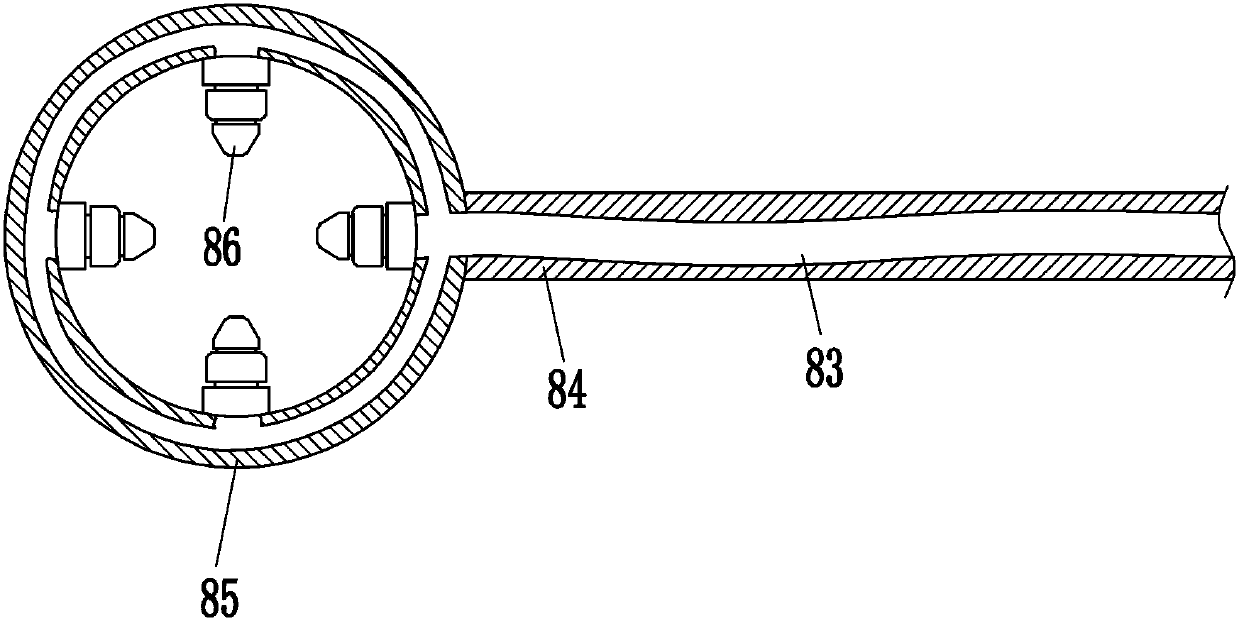

[0024] A construction steel bar derusting machine, such as figure 1 , figure 2 and Figure 5 As shown, it includes a support plate 1, a sliding rod 3, a sliding sleeve 4, a guide sleeve 41, a hollow guide rod 5, a wire brush 6, a torsion spring 61, a handle 7, a spray assembly 8 and a clamping assembly 9, and the support plate 1 There is a positioning groove 2 on the left side, and the top of the support plate 1 is bolted with a sliding rod 3 that acts as a guide. A sliding sleeve 4 is slidingly provided on the sliding rod 3. A guide sleeve 41 is installed on the lower part of the front side of the sliding sleeve 4. The guide sleeve 41 The inner sliding type is provided with a hollow guide rod 5, and the left end of the hollow guide rod 5 is rotationally connected with two wire brushes 6. Torsion spring 61, the right side of the top of the hollow guide rod 5 is connected with a handle 7, the upper part of the front side of the sliding sleeve 4 is provided with a spray assem...

Embodiment approach 2

[0031] On the basis of Embodiment 1, such as figure 2 and Figure 4 As shown, a pulling assembly 10 is also included, and the pulling assembly 10 includes a sliding sleeve 101, a sliding rod 102, a third spring 103, a clamping rod 104, a touch block 106 and a pull cord 107, and the right part of the hollow guide rod 5 is installed with The sliding sleeve 101 that plays a guiding role, the sliding sleeve 101 is slidingly provided with a sliding rod 102, the sliding rod 102 is wound with a third spring 103, one end of the third spring 103 is connected with the sliding sleeve 101, and the other end of the third spring 103 is connected with the sliding sleeve. The rod 102 is connected, the left end of the sliding rod 102 is rotatably connected to the clamping rod 104, the left side of the clamping rod 104 is connected to the pull rope 107, the two wire brushes 6 are connected to the pull rope 107, and the right side of the bottom of the hollow guide rod 5 has a special-shaped gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com