Roll paper full die-cutting waste removal device

A die-cutting and cardboard technology, which is applied to rotary printing machines, printing machines, printing machines, etc., can solve the problems of low efficiency, incomplete cleaning and low safety, and achieve the effect of convenient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

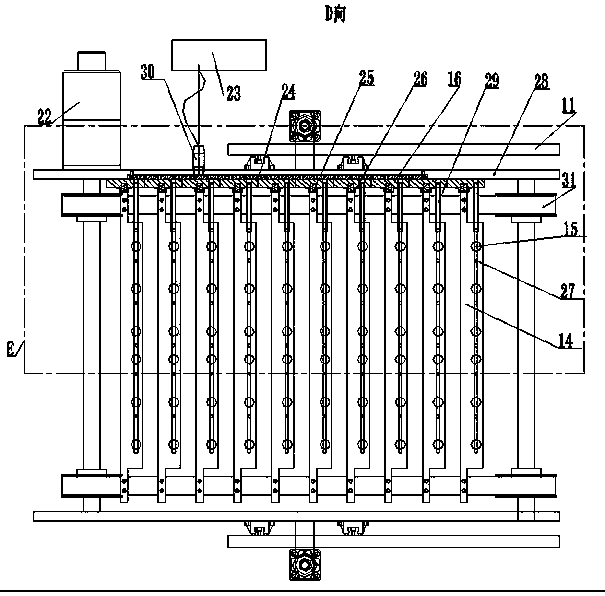

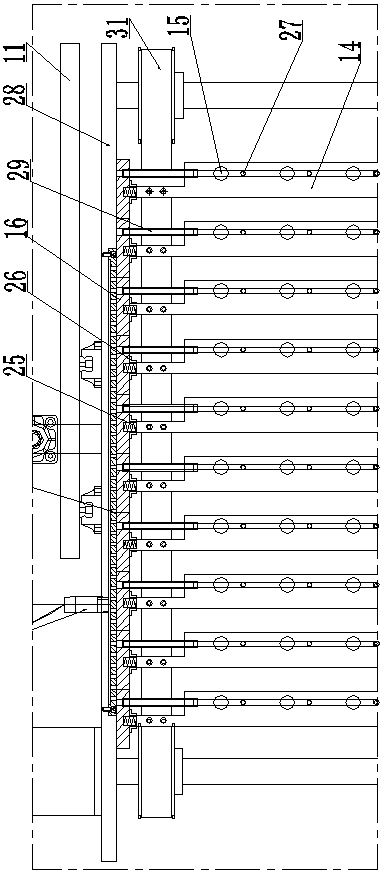

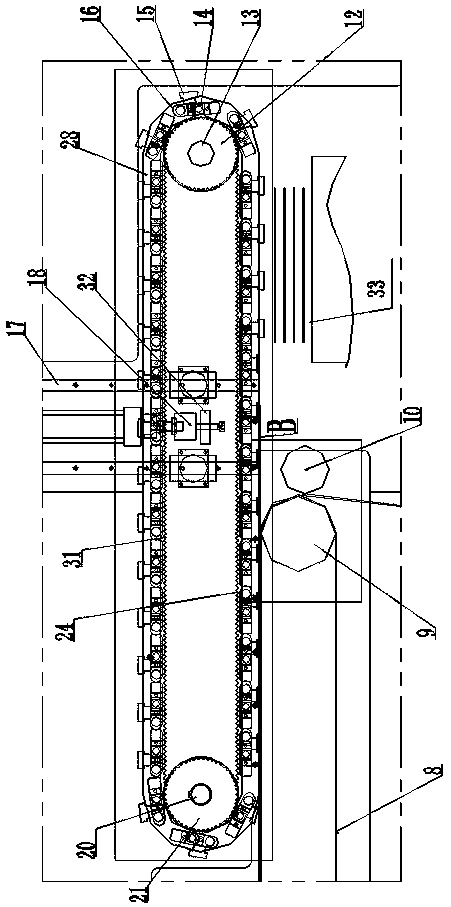

[0022] A roll jam full die-cut waste stripping device, see attached figure 1 to attach Figure 4 , in the figure: die-cutting fixed platform 1, die-cutting knife plate 2, die-cutting moving platform 3, die-cutting support plate 4, pulling support plate 5, die-cutting pulling roller 6, die-cutting pulling motor 6-1, Pulling and pressing roller 7, conveyor belt 8, waste edge pulling roller 9, waste edge pressing roller 10, finished product collection support plate 11, driven pulley 12, driven shaft 13, ventilation square shaft 14, finished product suction nozzle 15, Sealing block 16, linear guide rail slider group 17, cylinder connecting block 18, cylinder 19, driving shaft 20, driving pulley 21, motor 22, vacuum pump 23, ventilation plate 24, compression spring 25, sealing block guide sleeve 26, plug 27. Air suction distribution plate 28, connecting air pipe 29, air intake pipe 30, synchronous belt 31, limit adjustment block 32.

[0023] In this embodiment, it is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com