Process for improving flatness of installation plane of basin under sanitary ceramic table and installation quality of product

A technology for installing flat and sanitary ceramics, which can be used in ceramic molding machines, manufacturing tools, etc., and can solve problems such as the influence of adhesive glue and uneven installation surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A process for improving the flatness of the installation plane of the sanitary ceramic undercounter basin and improving the installation quality of the product, comprising the following steps:

[0030] A. Body forming:

[0031] A1, Mold Cleaning: Clean up impurities and dust in the mold; in this way, the surface flatness of the green body 2 can be maintained, and impurities are prevented from being mixed into the green body 2;

[0032] A2. Preparation before mold closing and grouting; to ensure the normal operation of pressure-holding and grouting, and improve the efficiency of grouting;

[0033] A3. Clamping and fixing;

[0034] A4, grouting: grouting into the mold cavity;

[0035] A5. Slurry suction forming and pressure holding;

[0036] A6, Pulping and consolidation;

[0037] A7. Open the mold and take off the blank.

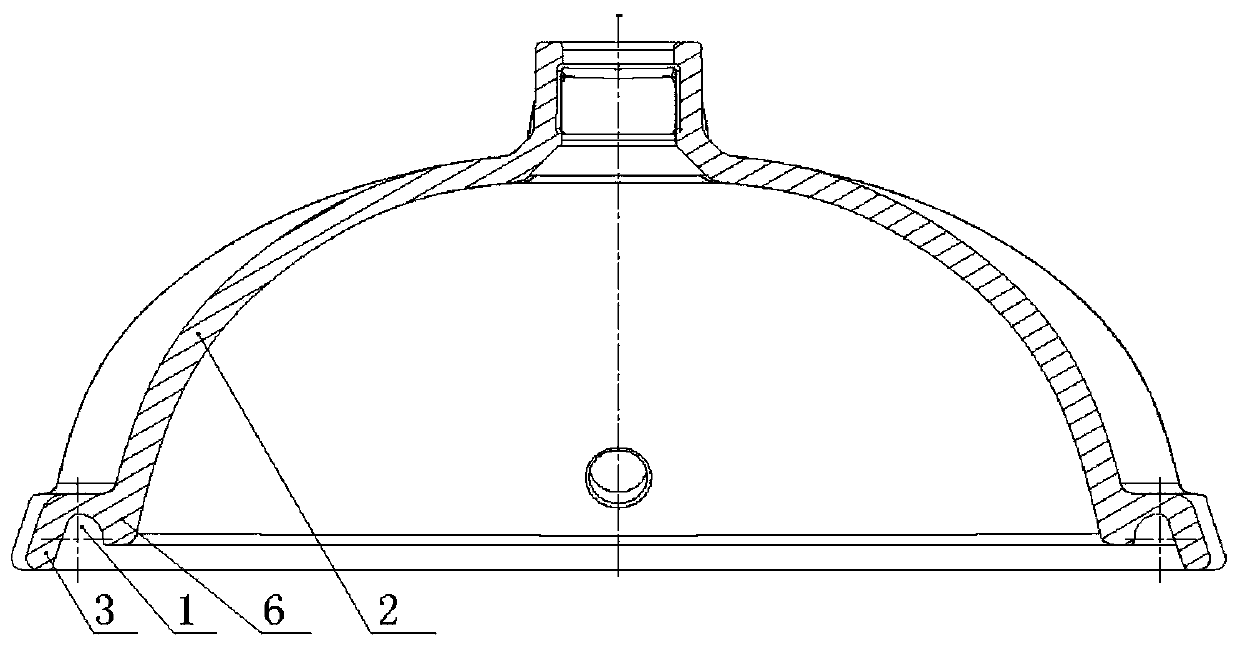

[0038] B. Drying of the green body: the formed green body 2 is inverted and dried naturally for 5 hours, such as figure 1 As shown, an annular g...

Embodiment 2

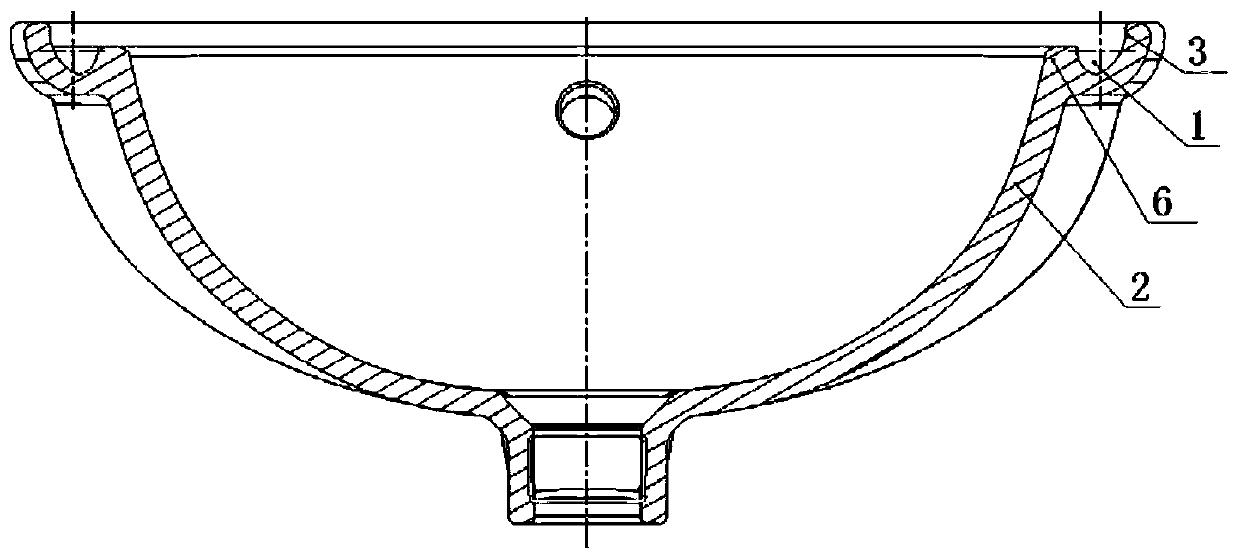

[0047] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the connection between the inner side wall of the outer edge 3 of the groove 1 and the bottom wall of the groove 1 of the formed undercounter basin product 5 is an arc transition, that is, as image 3 status shown. Compared with the angle between the inner wall and the bottom wall of the groove 1, the groove 1 can form a better anti-arch bridge structure, so that the groove 1 can be better connected with the green body 2 when the green body 2 is turned upside down and dried naturally. An arch bridge support is formed, thereby improving the stability of the green body 2 being inverted.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that, as figure 1 As shown, the height difference between the outer edge 3 and the inner edge 6 of the groove 1 is 10mm at the initial stage of drying, and 5mm at the later stage of drying. In the early stage of drying, the width of the groove 1 is 25mm, and the depth is 10mm; in the later stage of drying, the width of the groove 1 is 22mm, and the depth is 9mm.

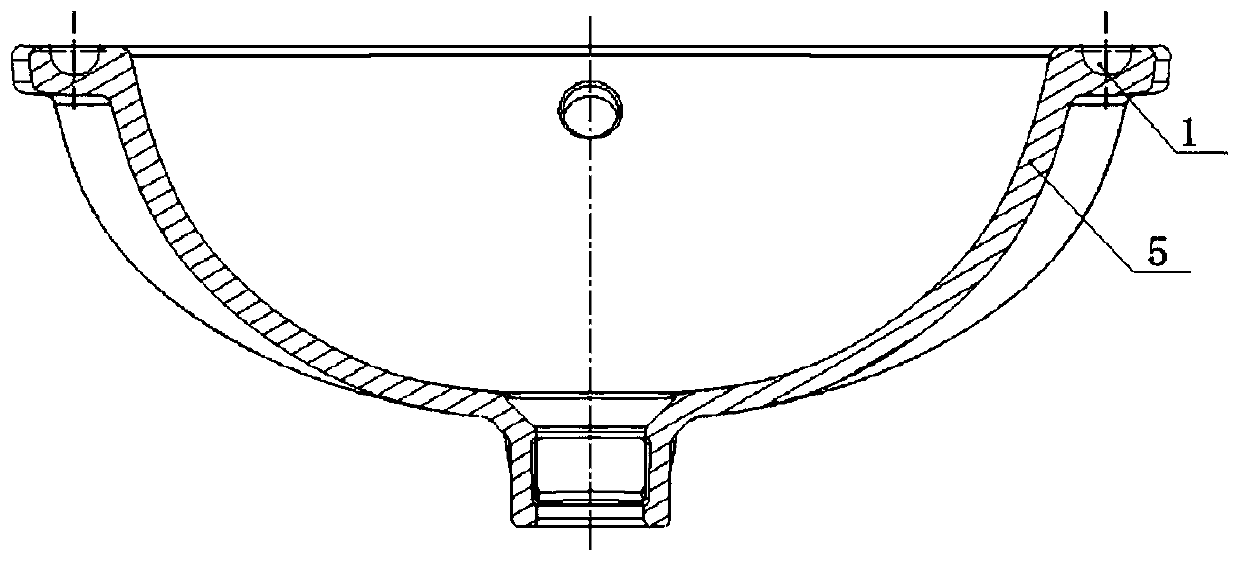

[0050] Such as figure 2 As shown, the height difference between the inner and outer edges of the groove 1 on the finished product 5 of the undercounter basin is zero, and the width of the groove 1 on the finished product 5 of the undercounter basin is 20mm and 8mm deep.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com