Small ceramic tile cutting machine

A technology for cutting machines and ceramic tiles, which is applied in the field of hardware, can solve the problems of reducing work efficiency and cumbersome operations, and achieve the effects of improving production efficiency, simple operation methods, and strengthening the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

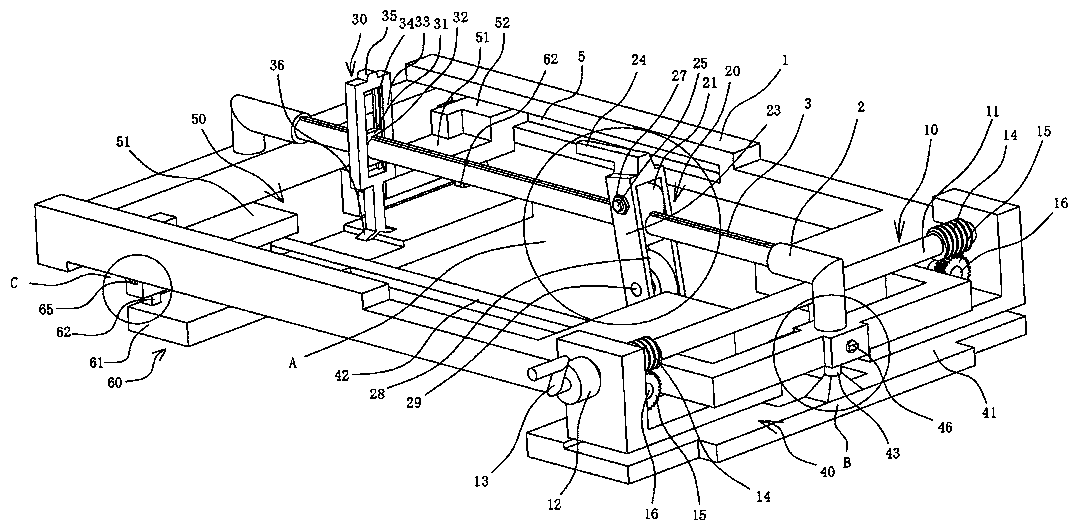

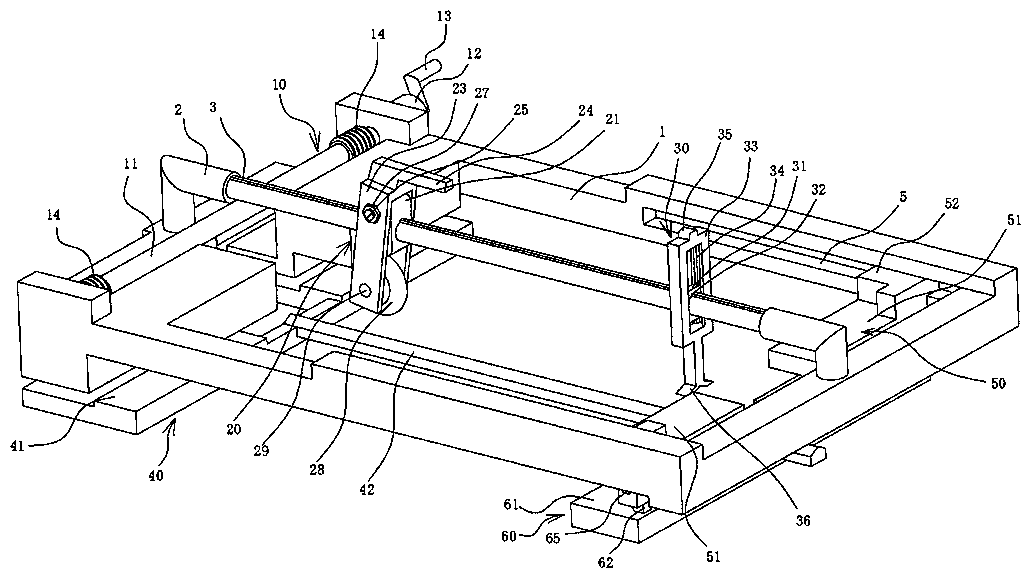

[0026] Such as figure 1 , figure 2 As shown, the small tile cutting machine of the present invention includes a frame 1, one end of the frame 1 is provided with a guide rail 2, a key 3 is provided in the middle of the guide rail 2, a moving mechanism 10 is provided at the right end of the frame 1 to drive the tiles to be cut, and the right end of the guide rail 2 A cutting mechanism 20 for cutting tiles is provided, a separation mechanism 30 for breaking tiles is provided at the left end of the guide rail 2, a first clamping mechanism 40 for clamping tiles is provided at the right end of the frame 1, and the clamping mechanism 40 is arranged below the moving mechanism 10, The left end of the frame 1 is provided with a sliding mechanism 50 that can slide in the frame 1 , and a second clamping mechanism 60 for clamping tiles is provided below the sliding mechanism 50 .

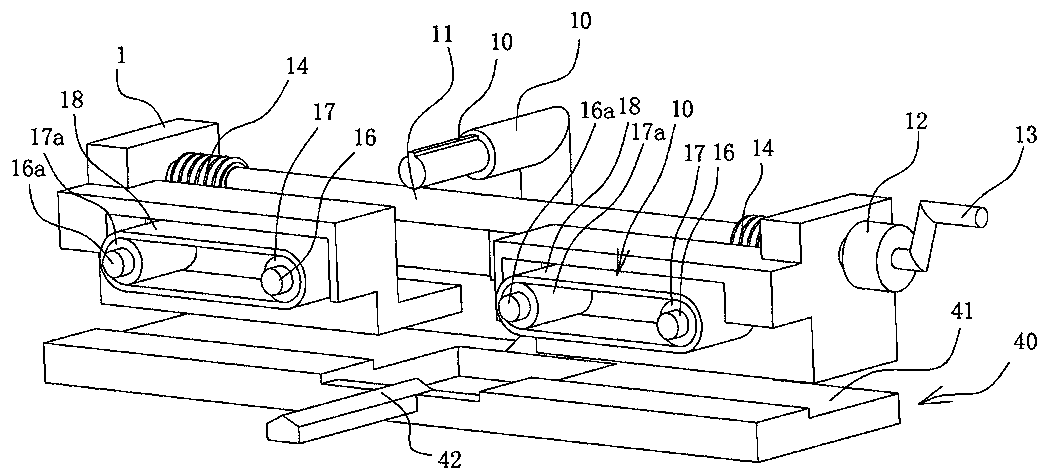

[0027] Such as figure 1 with image 3As shown, the moving mechanism 10 includes a worm 11, the worm 11 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap