On-line digital detection and feedback automatic correction device and method for out of roundness of PE pipe

A digital detection and roundness technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inaccurate PE pipes, unqualified product quality, low precision, etc., to avoid the expansion of accidents, simple and convenient layout The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

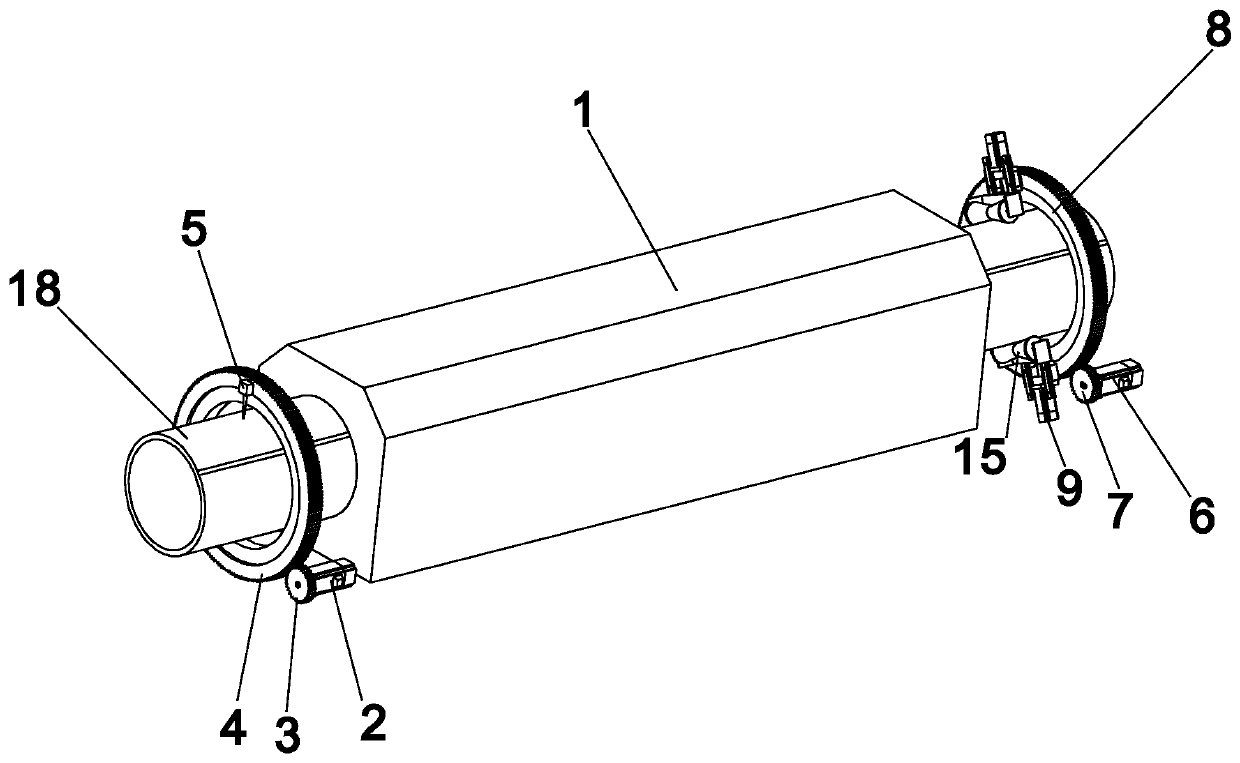

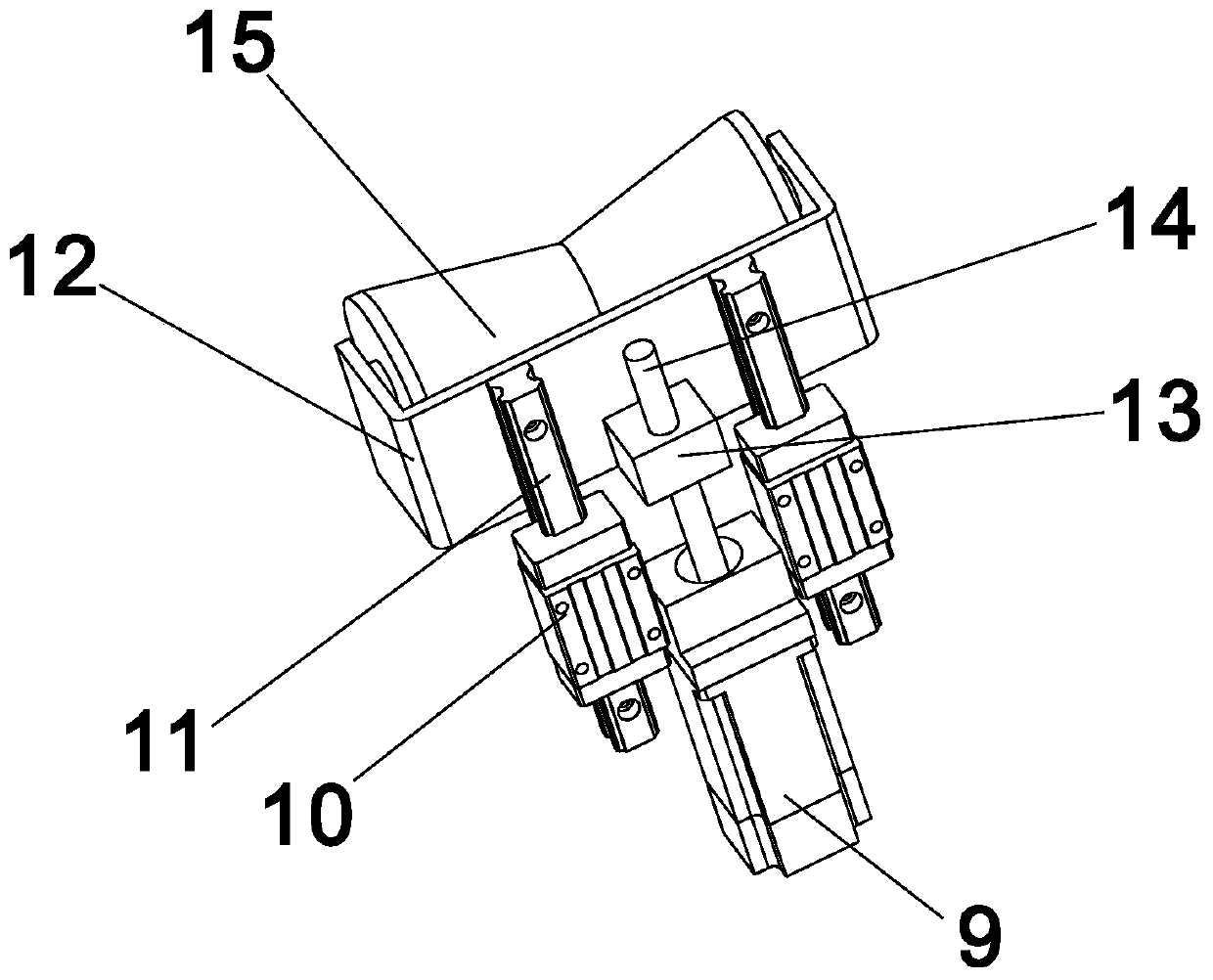

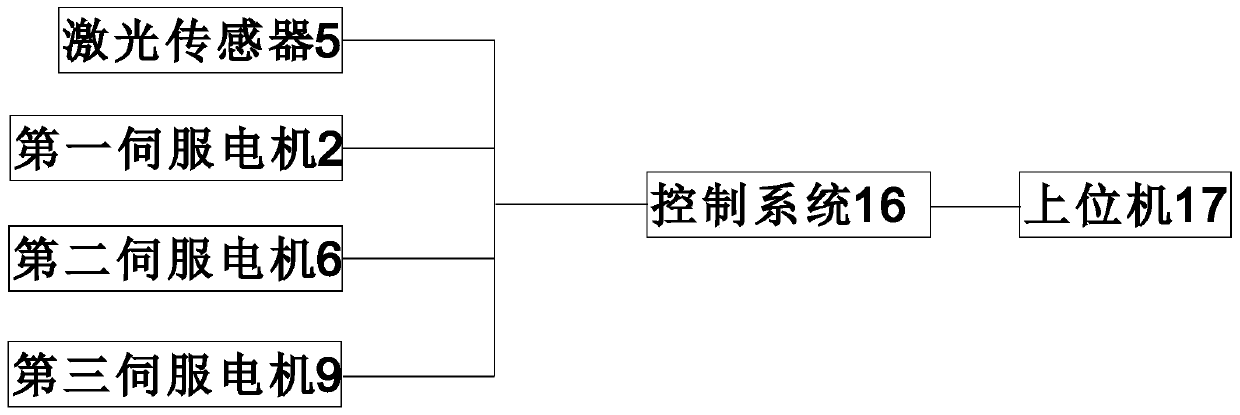

[0039]Such as Figure 1~Figure 3 As shown, the PE pipe out-of-roundness online digital detection and feedback automatic correction device includes a servo correction part arranged at the front end of the PE pipe cooling section 1, and a laser detection part arranged at the rear end of the PE pipe cooling section 1.

[0040] The PE pipe cooling section 1 includes a stainless steel shell, in which a plurality of spray heads are arranged, and the PE pipe is cooled by spraying cold water.

[0041] The laser detection part includes a first servo motor 2, the output shaft of the first servo motor 2 is connected to the first drive gear 3, the first drive gear 3 meshes with the toothed outer ring of the first slewing bearing 4, and the first slewing bearing The inner ring of 4 is fixed; the toothed outer ring of the first slewing support bearing 4 is equipped with a laser sensor 5 . The inner ring of the first slewing ring bearing 4 is fixedly installed on the machine platform at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com