Multifunctional horizontal type automatic boxing machine

An automatic cartoning machine, multi-functional technology, applied in the directions of packaging, transportation and packaging, single objects, etc., can solve the problems of messy box body, increase the workload, affect customers' unpacking and use, and reduce the workload of workers. The effect of improving packing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

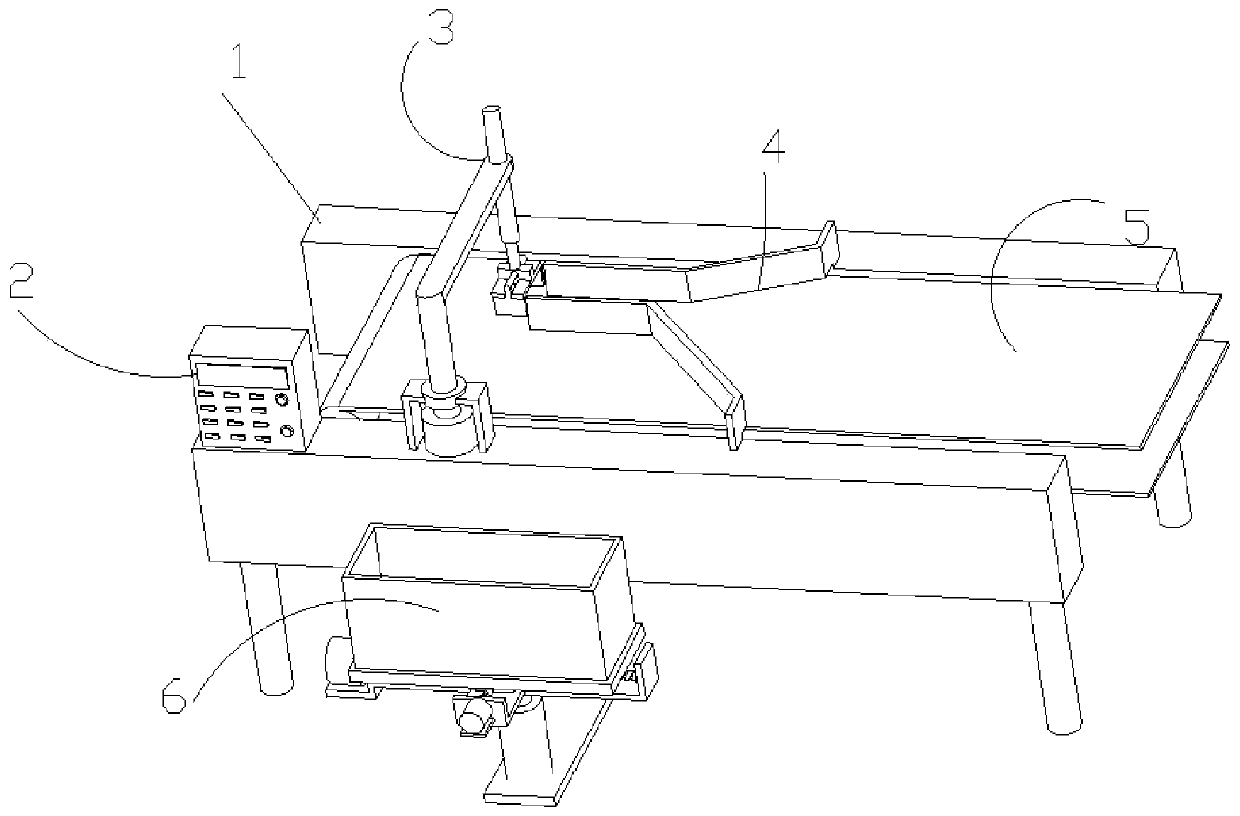

[0037]Such as figure 1 , 2 , 4 and 6, a multi-functional horizontal automatic cartoning machine, including a work frame 1, a controller 2 and a conveyor belt 5, the work frame 1 is connected to the conveyor belt 5 through the rotation of the rotating shaft, and the work frame 1 is symmetrically fixedly connected with a guide material Structure 4, material guide structure 4 includes straight plate 41, inclined plate 42 and connecting plate 43, connecting plate 43 is fixedly connected with inclined plate 42 for guiding, inclined plate 42 is fixedly connected with straight plate 41, connecting plate 43 is fixedly connected with working frame 1 , a controller 2 and a clamping structure 3 are fixed on the working frame 1, the controller 2 includes a control host, a display screen and an operation keyboard, the controller 2 is electrically connected to an external power supply, and the controller 2 is connected to the first electric push rod 35 respectively. , the second electric p...

Embodiment 2

[0039] Embodiment 2 is a further improvement on Embodiment 1.

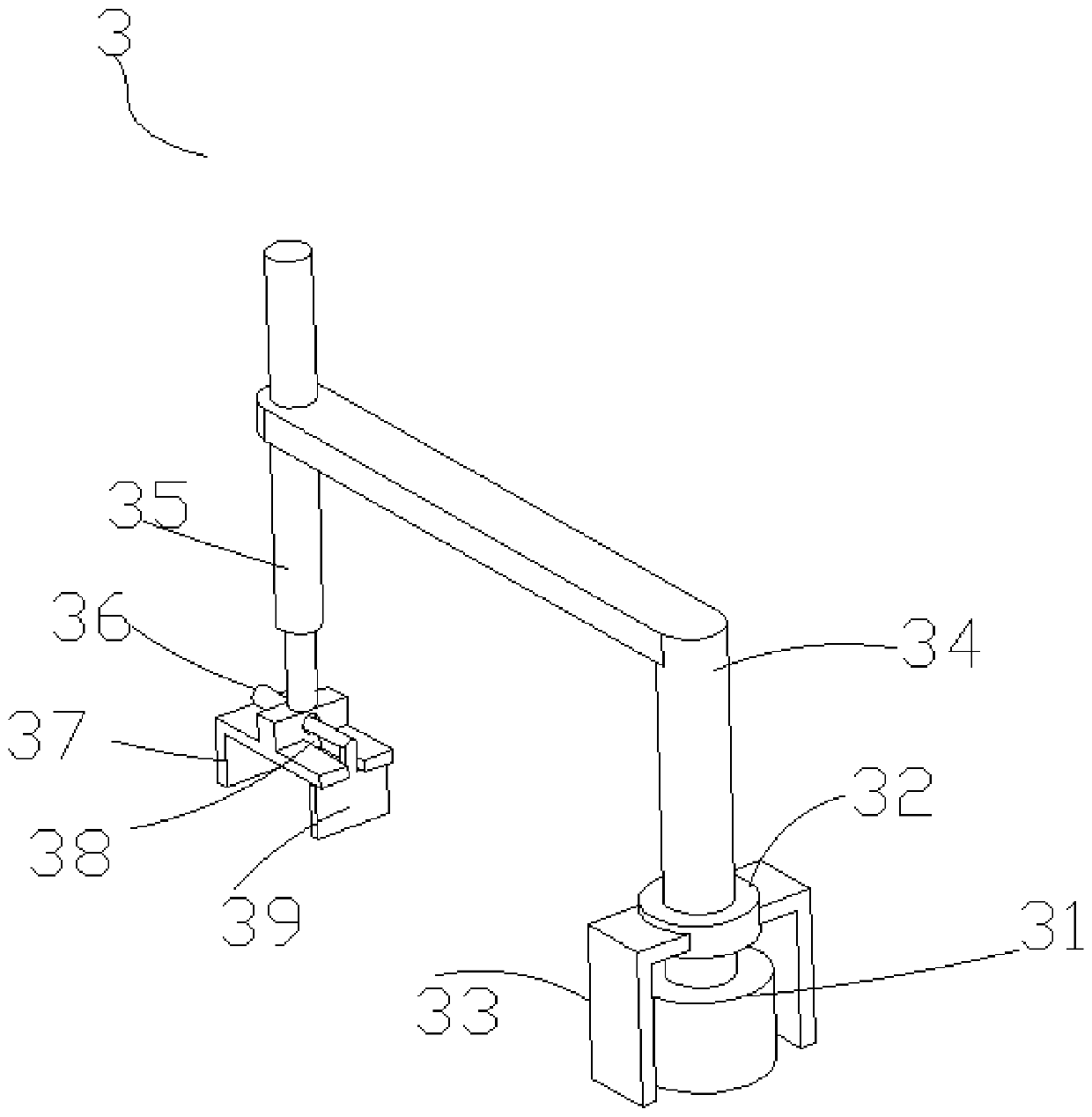

[0040] Such as figure 1 , 2 And 3, the clamping structure 3 includes a rotating motor 31, a support bearing 32, a support plate 33, an L-shaped plate 34, a first electric push rod 35, a second electric push rod 36 and an L-shaped splint 37, and the top of the L-shaped splint 37 is opened There are chute 38, T-shaped slide plate 39 and chute 38 sliding connection, support plate 33 and rotating motor 31 are all fixedly installed on the work frame 1, support plate 33 tops are fixedly connected with the outer ring of support bearing 32, support bearing 32 The inner ring is fixedly connected with the output end of the rotating motor 31 and the L-shaped plate 34. The L-shaped plate 34 is not in direct contact with the rotating motor 31, which can prolong the service life of the rotating motor 34. The lateral part of the L-shaped plate 34 is fixedly installed in the through hole There is a first electric push rod 35, a...

Embodiment 3

[0042] Embodiment three is a further improvement on embodiment two.

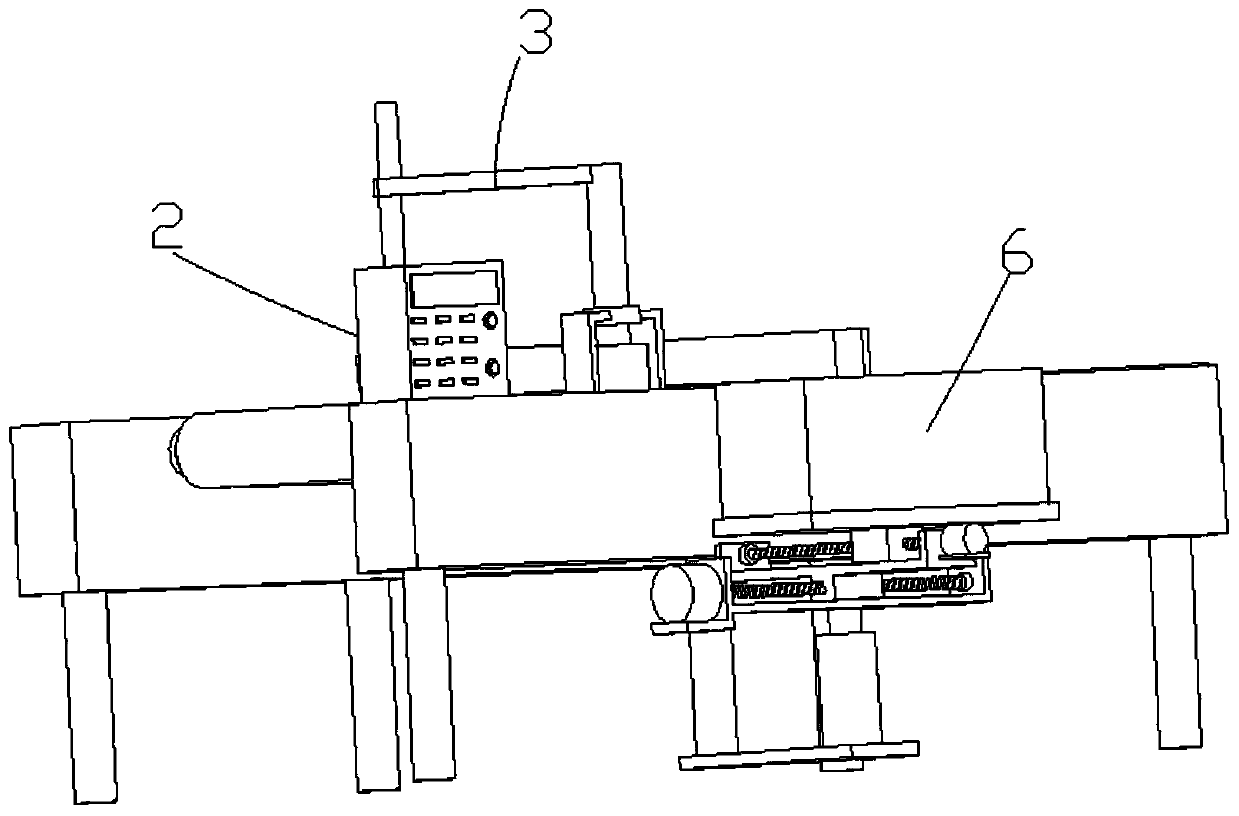

[0043] Such as figure 1 , 2 and 5, the bottom of the mounting frame 1 is provided with a practical box moving structure 6 that cooperates with the clamping structure 3, and the box moving structure 6 includes a horizontal plate 61, a first threaded rod 62, a first drive motor 63, a second threaded rod 64, box body 65, first slider 66, support frame 67, second drive motor 68, first U-shaped plate 69, second slider 610, hydraulic cylinder 611 and second U-shaped plate 612, on the horizontal plate 61 A hydraulic cylinder 611 is fixedly installed, and the telescopic end of the hydraulic cylinder 611 is fixedly connected with a first U-shaped plate 69, and the first U-shaped plate 69 is rotatably connected with a first threaded rod 62 through a fixedly connected bearing, and the first threaded rod 62 is connected to the first threaded rod 62. The output end of a driving motor 63 is fixedly connected, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com