Flexible self-adaptive hub carrying mechanical arm

An adaptive and manipulator technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that it is difficult to complete the grabbing and handling of wheels of different sizes and specifications, and it is difficult to realize flexible manufacturing, so as to achieve stable clamping force, The effect of great flexibility and simple transmission mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

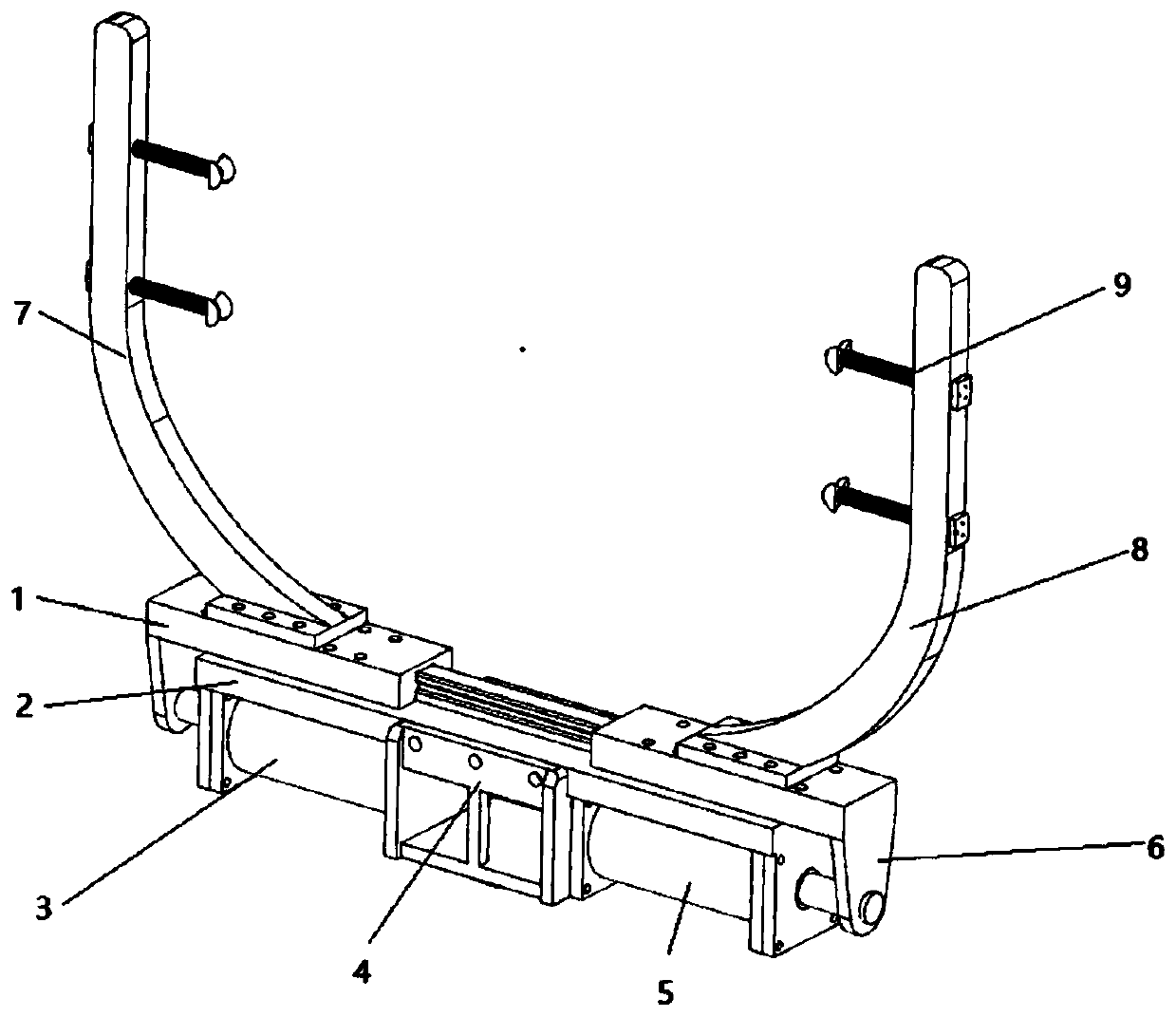

[0020] The following is based on Figure 1 to Figure 6 To further explain the specific implementation of this patent:

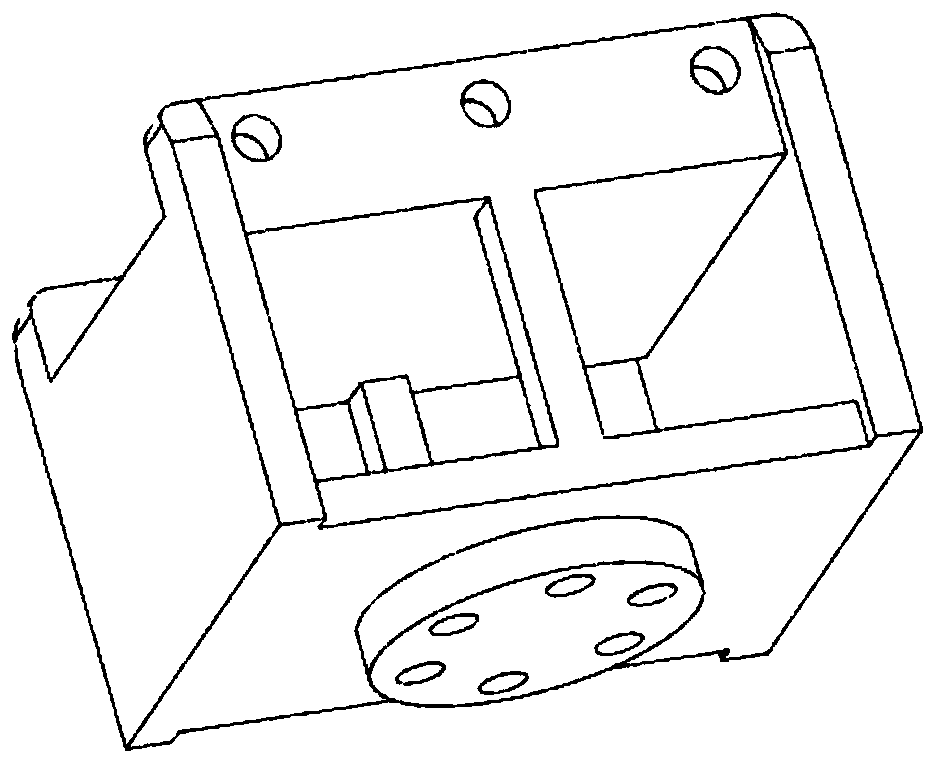

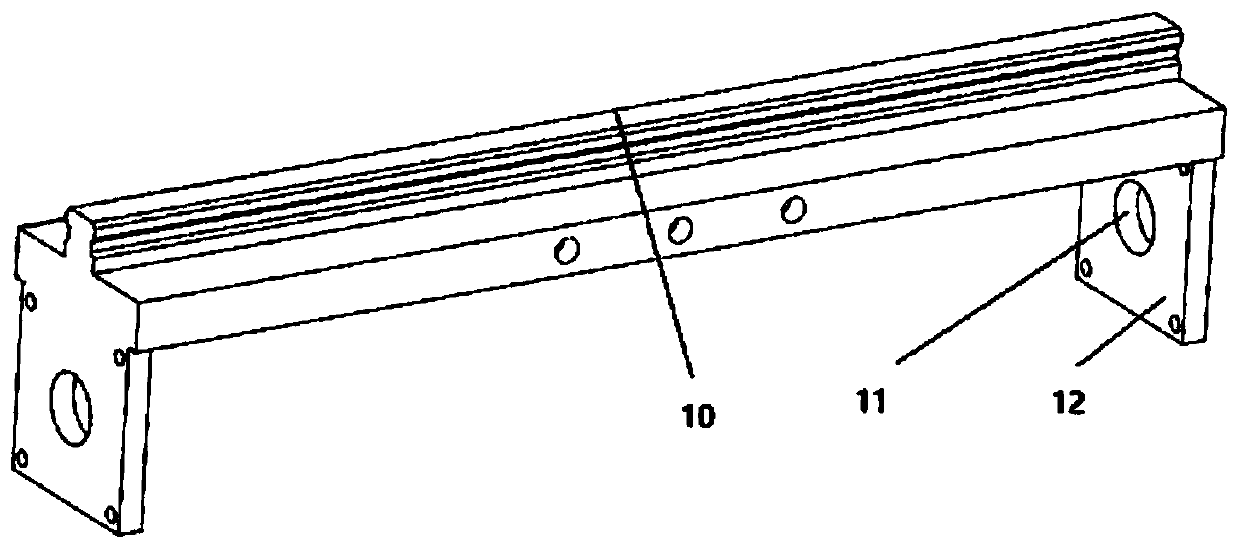

[0021] like figure 1 As shown, a flexible adaptive hub handling manipulator includes a support frame 4, a left cylinder 3, a right cylinder 5, a fixed base 2, a left moving base 1, a right moving base 6, a left finger Type jaw 7, right side finger type jaw 8 and fingertip gripper 9. Described support frame 4 plays the effect of overall support, and structure is as follows figure 1 shown. The left side of the support plate 4 is connected with the left cylinder 3 , and the right side is connected with the right cylinder 5 . The top of the support plate 4 is connected with the fixed base 2 . like image 3 As shown, the top surface of the fixed base 2 is provided with a guide rail 10, and the bottoms of the left mobile base 1 and the right mobile base 6 are provided with a guide rail groove 13 that is slidably connected with the guide rail 10 (such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com