Intelligent unmanned topspeed loading system for container loading

A container, intelligent technology, applied in loading/unloading, transportation and packaging, conveyor control devices, etc., can solve the problems of increasing the vibration and shaking of the carrier plate, uneven support force, difficult to achieve synchronous lifting, etc., to reduce vibration. and the degree of shaking, the effect of preventing the concentration of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

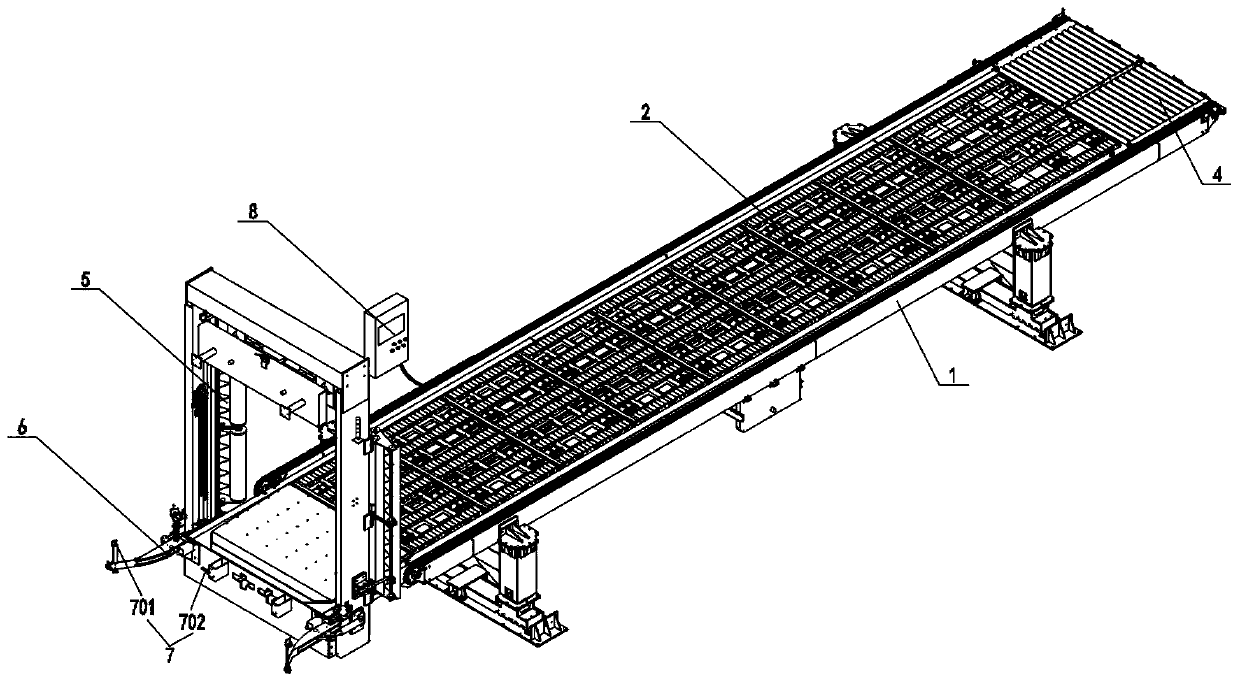

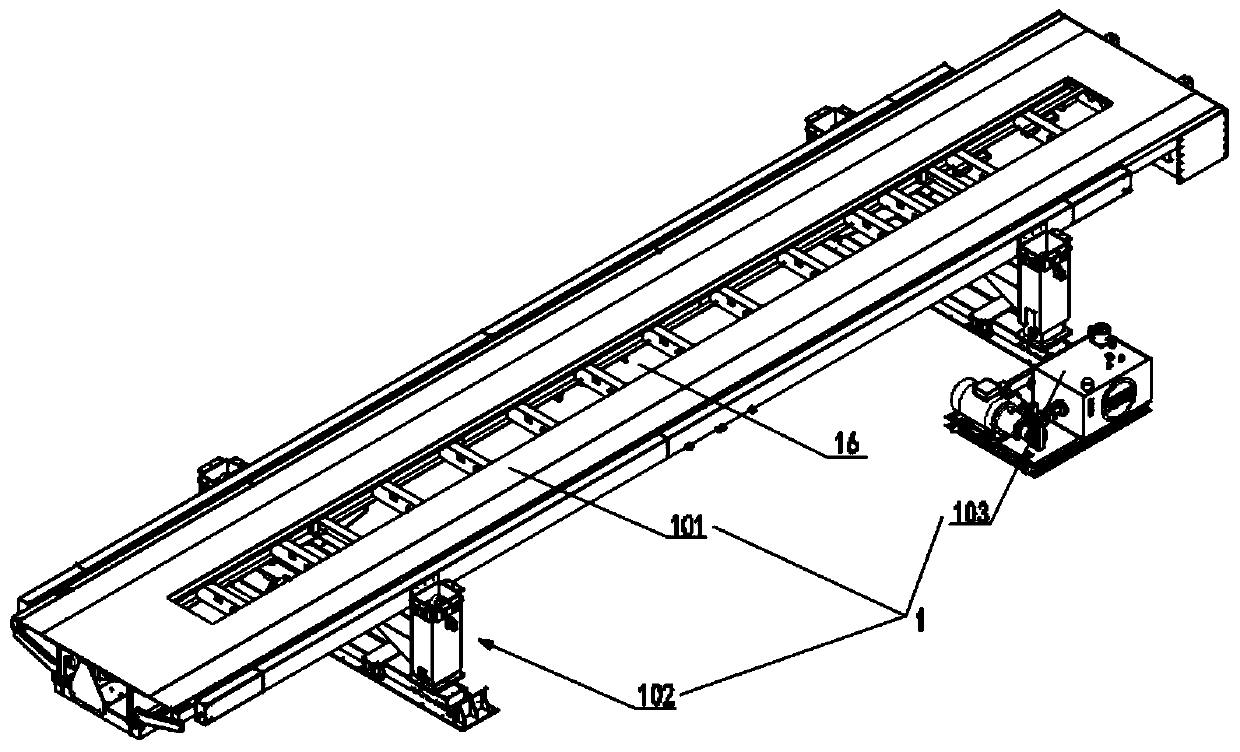

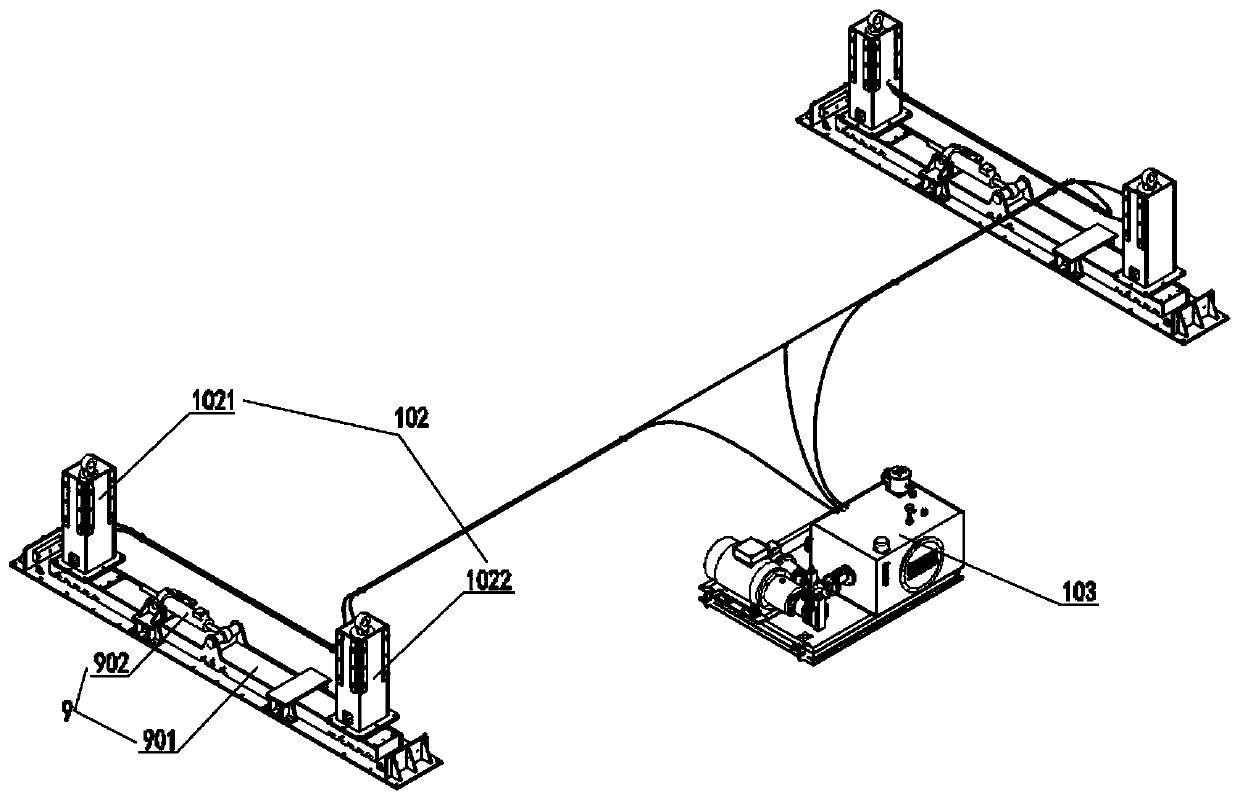

[0039] refer to Figure 1-13 , an intelligent unmanned extreme-speed loading system for container loading, comprising an adaptive platform mechanism 1, an adaptive carrier mechanism 2, a carrier driving mechanism 3, a platform connection limit mechanism 6, a compartment sensing mechanism 7 and an electric control system 8 (the electric control system 8 adopted in the present embodiment is a programmable PLC encoder), the self-adaptive platform mechanism 1 includes a support platform 101 and two groups of hydraulic support mechanisms 102 fixed at the front and rear ends of the support platform 101, Both groups of hydraulic support mechanisms 102 include a supporting main hydraulic cylinder 1021 and a supporting auxiliary hydraulic cylinder 1022. The rodless en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com