Balance mechanism of crane

A technology of balance mechanism and crane, which is applied in the direction of cranes, load hanging components, transportation and packaging, etc. It can solve problems such as crane tipping, inability to dynamically give balance force to crane boom, and lifting weight not reaching the designed lifting weight. , to achieve the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

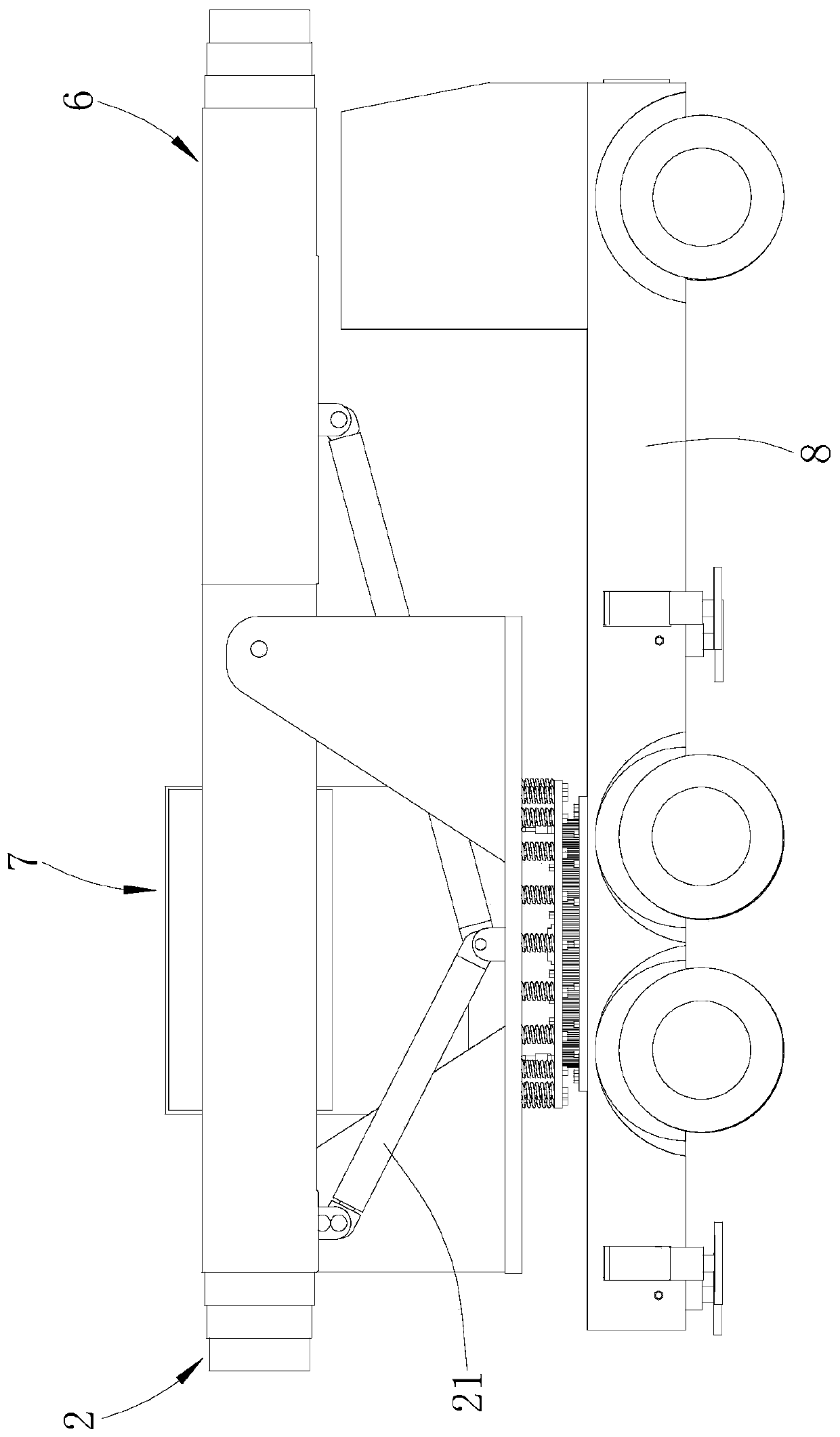

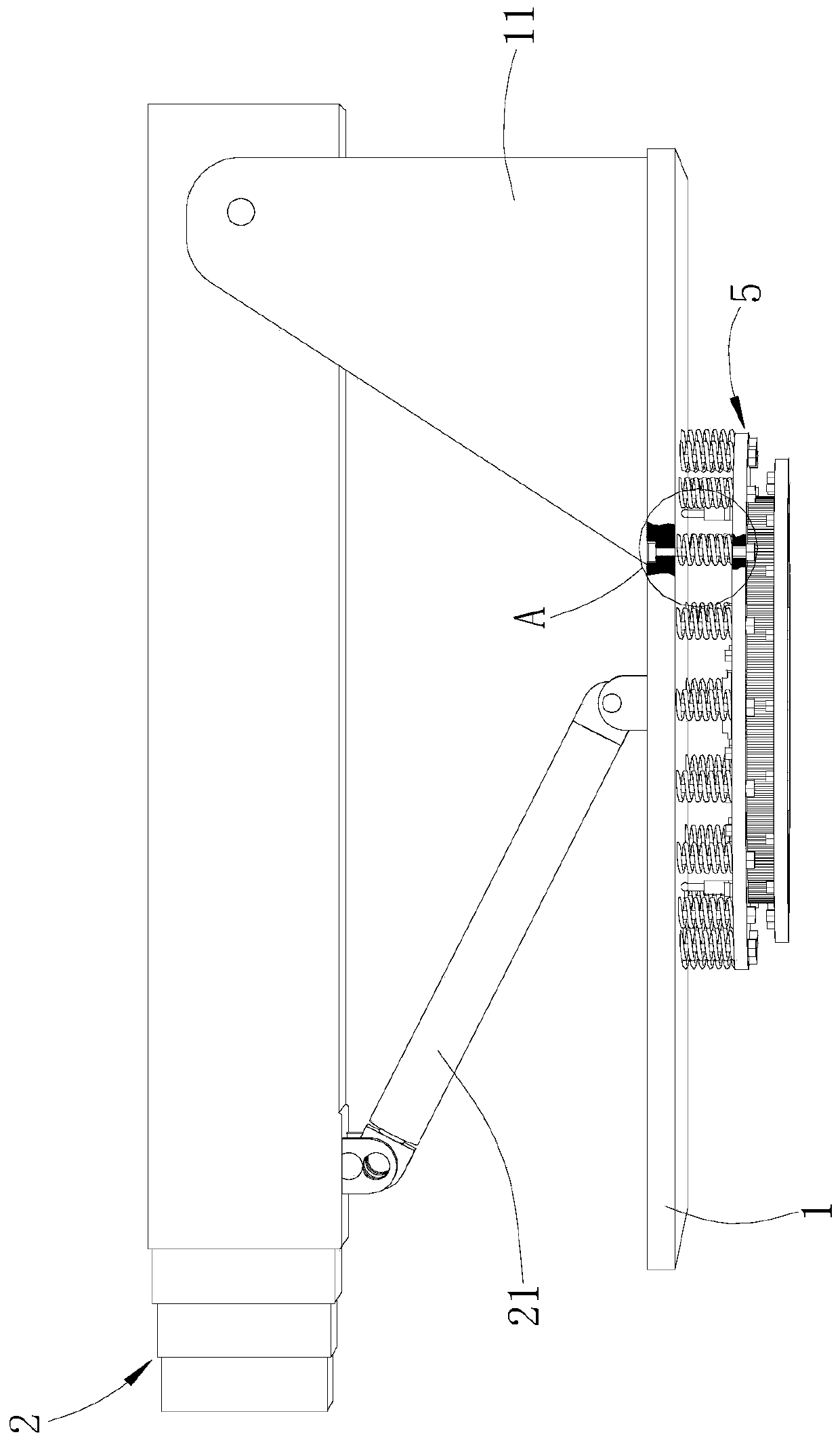

[0024] Such as Figures 1 to 4 shown (for simplicity of view, figure 1 The hooks, winches and other equipment of the original truck crane are not shown in the figure 1 and figure 2 Also do not show the supporting hook and hoisting equipment of counterweight boom 2 in the middle).

[0025] This balance mechanism is installed on the existing truck crane, and the main equipment such as frame 8, lifting arm 6, winch, drive system, hydraulic system, steering system, winch system, control system and so on of the original truck crane are used. The truck crane uses a turntable slewing mechanism.

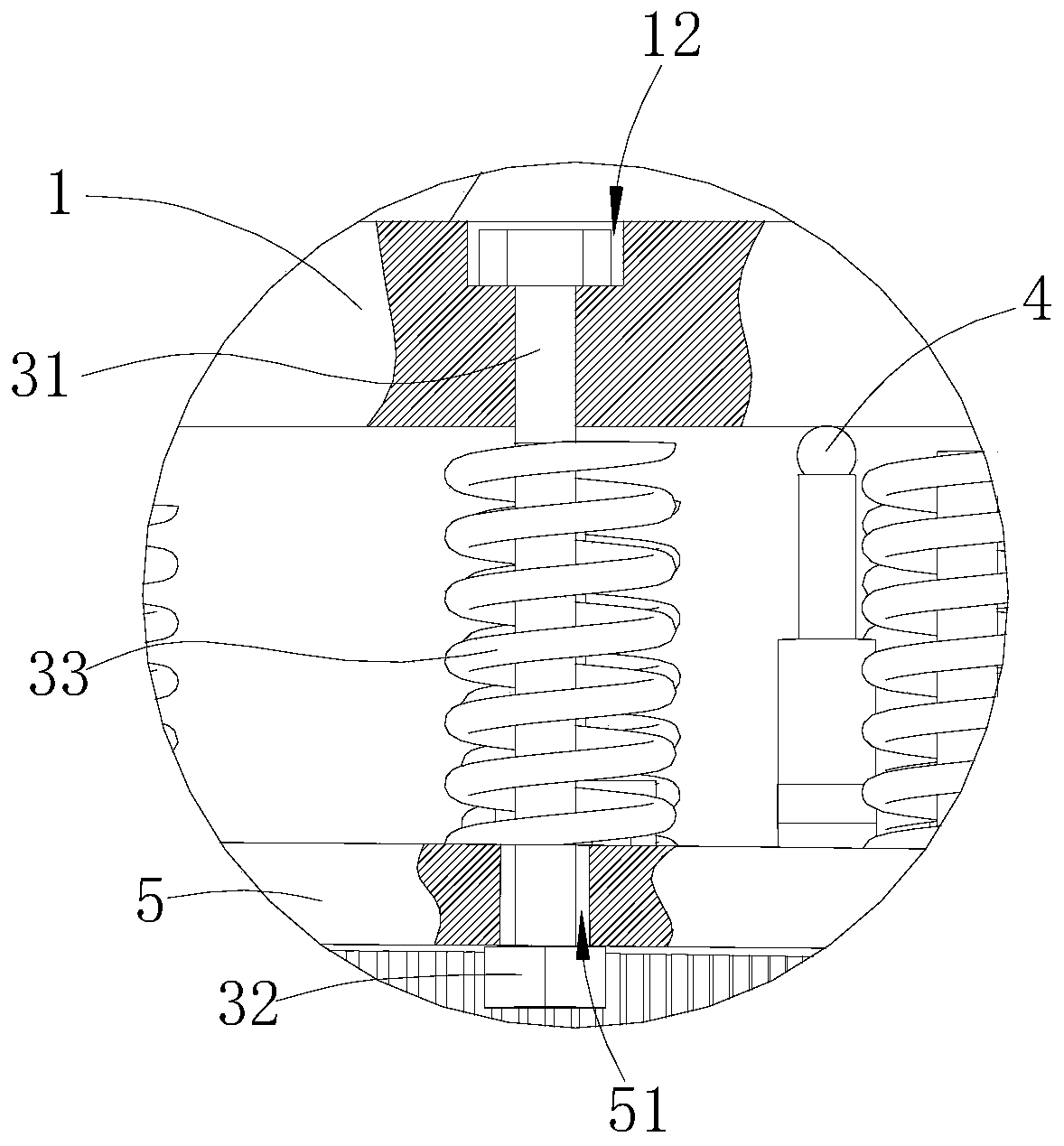

[0026] The balance mechanism comprises a balance plate 1, a counterweight suspension arm 2, four load cells 4 and twenty groups of elastic components.

[0027] The lifting arm 6 of the crane is installed on the upper side of the balance board 1, and the hoisting control room 7 of the crane is also installed on the balance board 1. The hinge seat 11 is welded on the balance board 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com