Transmission device and method for manufacturing same

A transmission device and cooling element technology, which is applied to transmission device parts, chemical instruments and methods, mechanical equipment, etc., and can solve the problems of increased shell weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

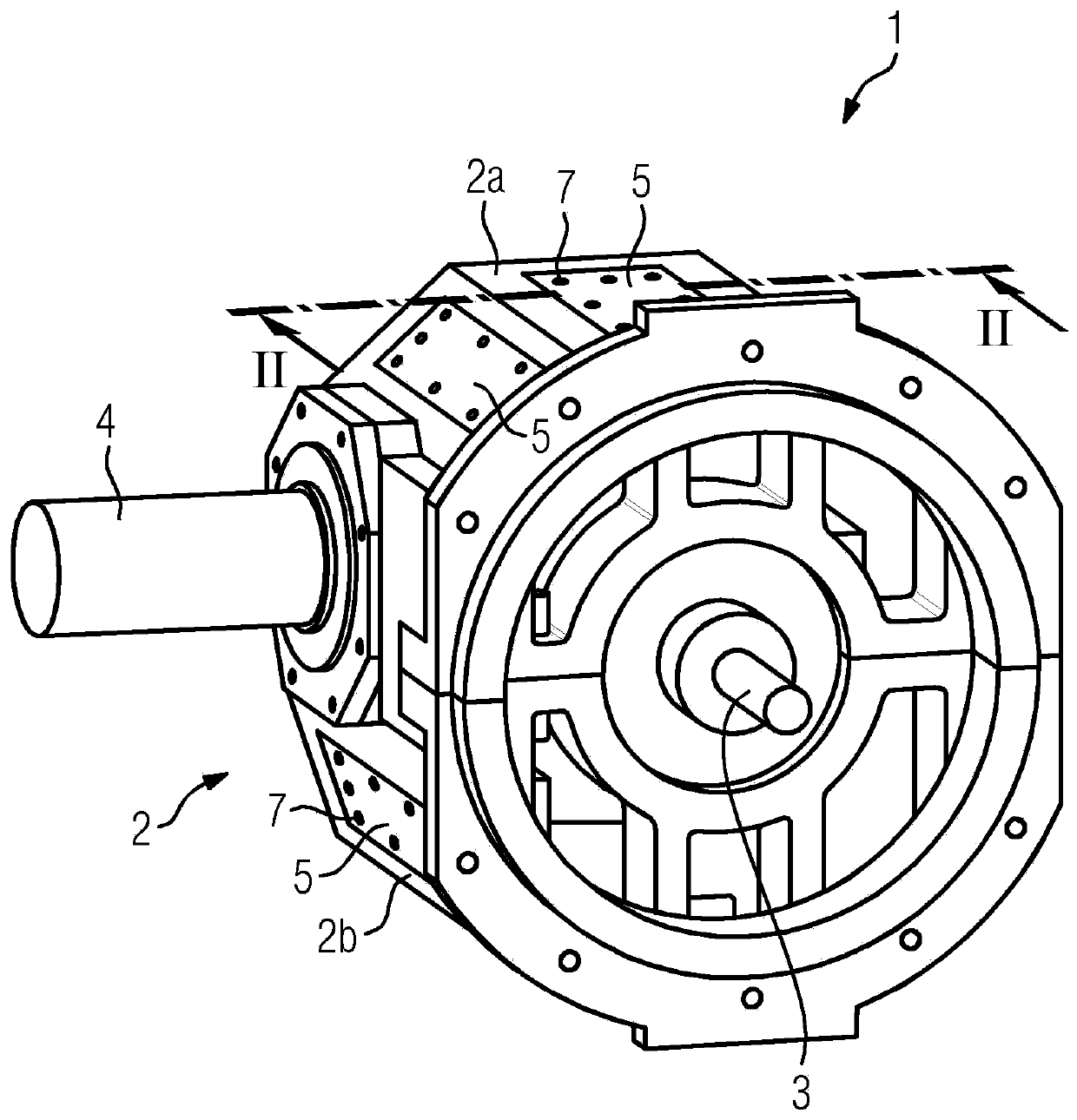

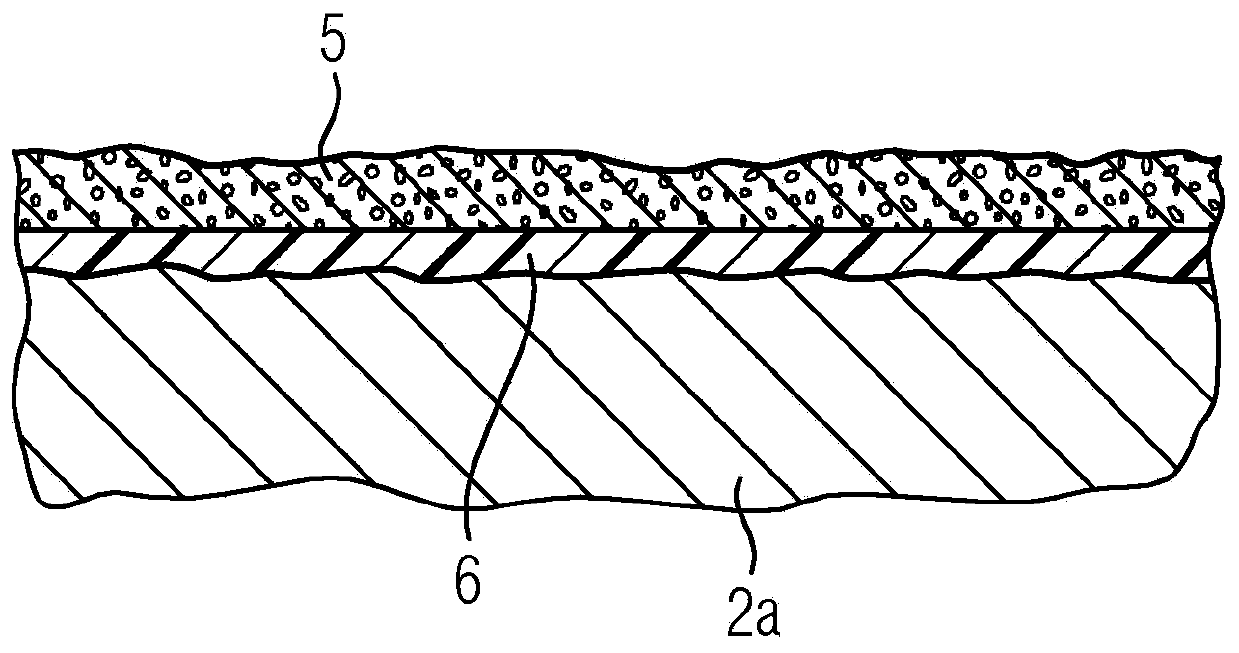

[0016] figure 1 A transmission 1 according to an embodiment of the invention is shown, wherein this is a spur gear designed as a bevel spur gear. Obviously, however, the specific transmission type is not critical to the invention. The transmission 1 has a housing 2 which is divided into an upper housing part 2a and a lower housing part 2b. The upper housing part 2 a and the lower housing part 2 b are here symmetrically constructed and can be cast in the same mold, wherein this is not mandatory. The transmission 1 also comprises a drive shaft 3 and a driven shaft 4 through which the drive power enters the transmission 1 and which is connected to a device not shown, for example a conveyor belt device (for example only). A cooling structure in the form of a cooling element 5 made of open-celled metal foam is arranged on the outer side of the housing 2 , the cooling structure being fastened on the housing 2 as a separate component. The cooling element 5 is currently designed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com