Upstream pumping mechanical seal ring having elliptical grooves

A mechanical seal, elliptical technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as easy leakage, poor sealing effect, etc., to prolong the life of the seal, facilitate design and production, and uniform pressure distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

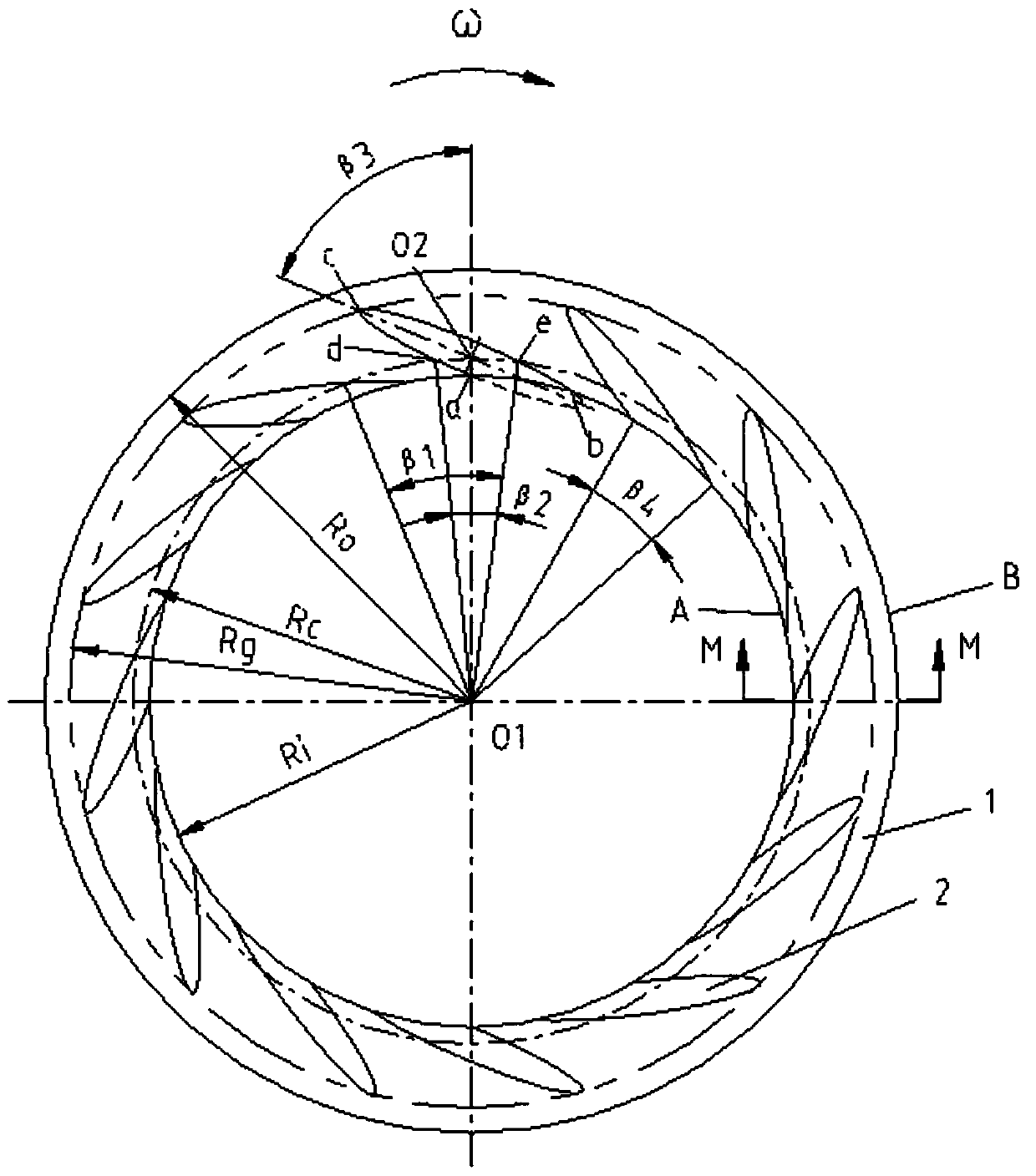

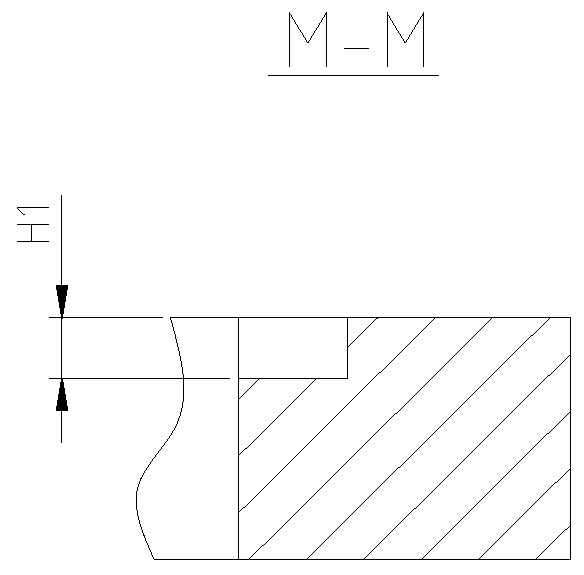

[0030] The present invention provides an upstream pumping mechanical seal ring with an oval groove, such as figure 1 and figure 2 As shown, the sealing ring includes a moving ring and a static ring, the moving ring and the static ring are provided with a sealing end face 1, and at least one sealing end face 1 of the moving ring and the static ring is provided with a plurality of elliptical fluids uniformly distributed along the circumferential direction The dynamic pressure groove 2, the fluid dynamic pressure groove 2 includes notches ab, upstream surface ac and backflow surface bc connected in sequence. The notch ab is set on the low-pressure side A of the sealing end face 1, that is, the inner side of the sealing end face 1 in the figure; The direction of rotation of the moving ring is opposite.

[0031] Specifically, in the figure: ab is the notch; ac is the upstream surface; bc is the backflow surface; A is the low pressure side; B is the high pressure side; L1 is the ...

Embodiment 2

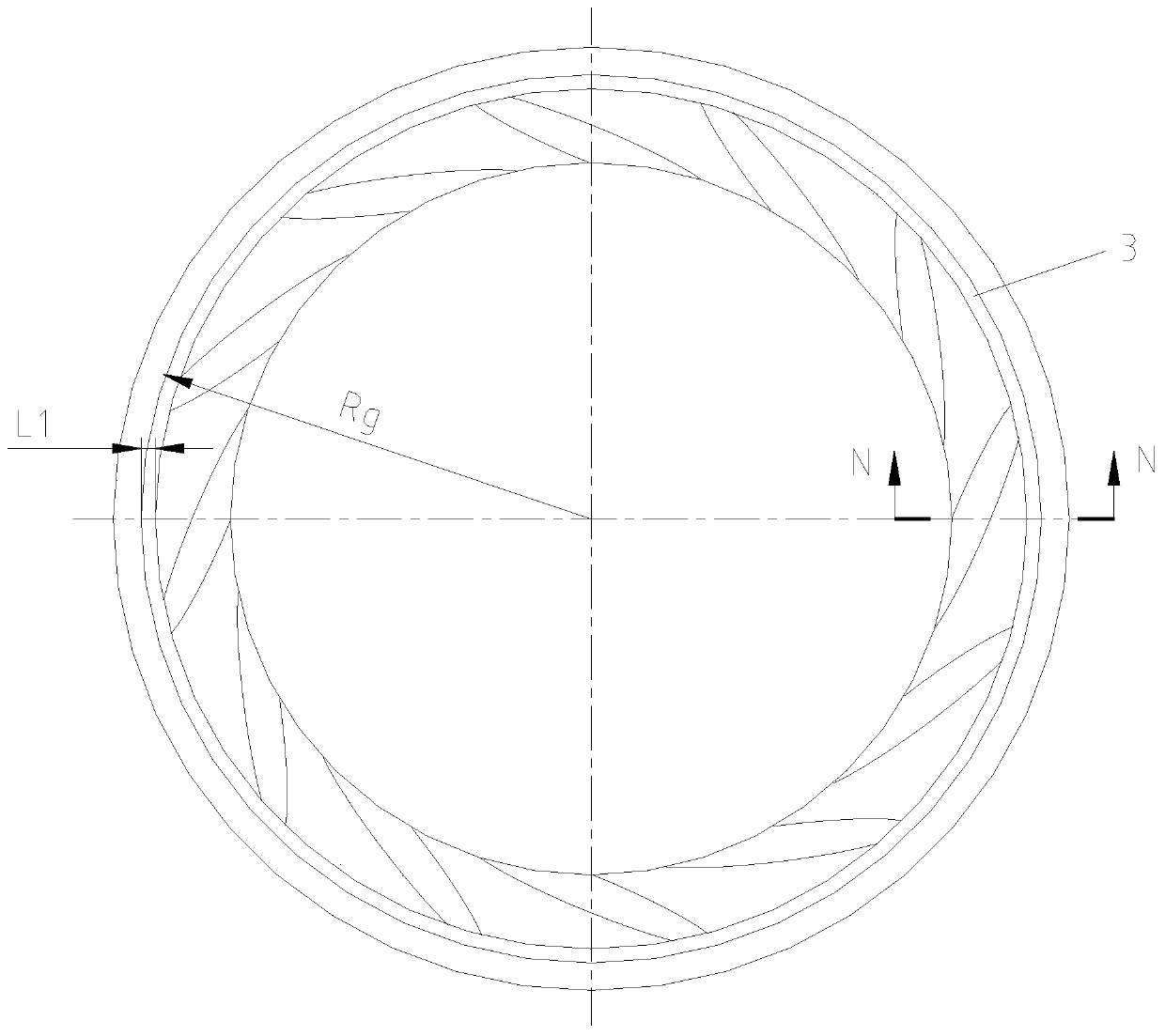

[0035] This embodiment is an embodiment improved on the basis of the first embodiment. Such as image 3 and 4As shown, the upstream pumping mechanical seal ring with an elliptical groove in this embodiment is also provided with an annular pressure equalizing groove 3 on the sealing end face 1, and the annular pressure equalizing groove 3 is arranged on the side of the fluid dynamic pressure groove 2 away from the notch. On one side, the annular pressure equalizing groove 3 runs through and communicates with a plurality of fluid dynamic pressure grooves 2 . The groove depth of the annular pressure equalizing groove 3 is 1-50 μm, and the groove depth of the annular pressure equalizing groove 3 is equal to or smaller than that of the fluid dynamic pressure groove 2 . The radial width of the annular pressure equalizing groove 3 is 0.5-3 mm. The annular pressure equalizing groove 3 connects each fluid dynamic pressure groove 2 at the root of the groove, so that the pressure dist...

Embodiment 3

[0037] This embodiment is also an embodiment improved on the basis of the first embodiment. Such as Figure 5 and 6 As shown, the upstream pumping mechanical seal ring with an elliptical groove in this embodiment is also provided with an annular grit chamber 4 on the end face, and the annular grit chamber 4 is arranged at a certain position in the middle of the hydrodynamic pressure groove 2. The annular grit chamber 4 runs through and communicates with a plurality of fluid dynamic pressure grooves 2 . The depth of the annular grit chamber 4 is 20 μm to 3 mm, and the depth of the annular grit chamber 4 is greater than or equal to the depth of the hydrodynamic pressure chamber 2 . The radial width of the annular grit chamber 4 is 0.5-3mm. The annular grit chamber 4 can accommodate particles in the fluid, preventing the particles from damaging the sealing end face 1 of the sealing ring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com