Device and method of monitoring state of working medium in compression refrigeration system operation

A compression refrigeration and refrigeration system technology, applied in the direction of refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of refrigerant loss, difficult to obtain value data, and difficult to eliminate faults, so as to prevent damage and protect the natural environment , the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

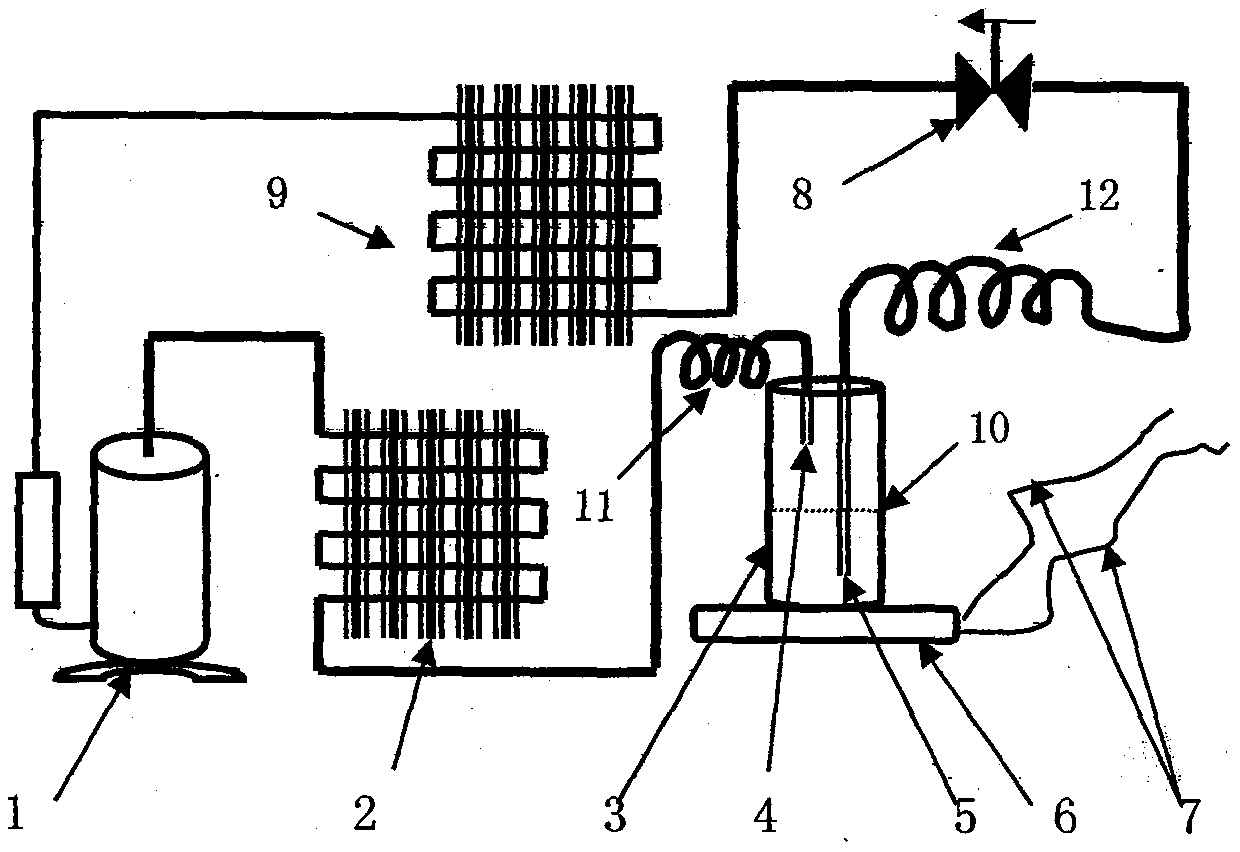

[0023] figure 1 Among them, the connecting pipe (11) between the liquid storage tank and the condenser and the connecting pipe (12) between the liquid storage tank and the throttle valve adopt a non-load-bearing connection, and the connecting pipe can be a common connecting hose or The influence of pipeline connection on the weight measurement of the liquid storage tank is reduced by the spiral shape or the twisted shape. Since the unit weight increases greatly after the refrigerating medium is liquefied, a little involvement does not hinder the judgment of faults and other situations.

[0024] figure 1 Middle (6) can be made of a pressure sensor and a corresponding spring or a flexible base to become a base with an emphasis function; they can be a tension lifting detection device made of a tension sensor component; they can also be a device made of a tension switch or a pressure switch Direct alarm or direct control.

[0025] When the refrigeration system is shut down, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com