Heating furnace discharged ground roller cooling structure

A cooling structure and heating furnace technology, applied in the field of iron and steel smelting and processing, can solve problems such as increasing the frequency of oil replenishment, lack of ground rollers, interrupted maintenance of the production line, etc., to reduce the stuck situation, reduce the frequency of occurrence, and stabilize and concentrate the flow direction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

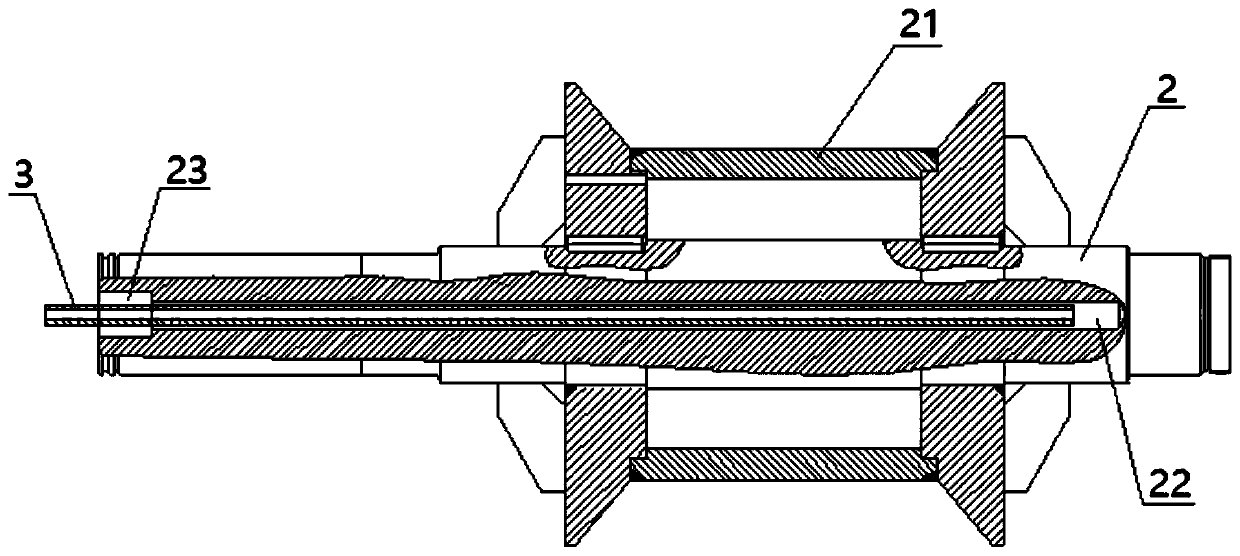

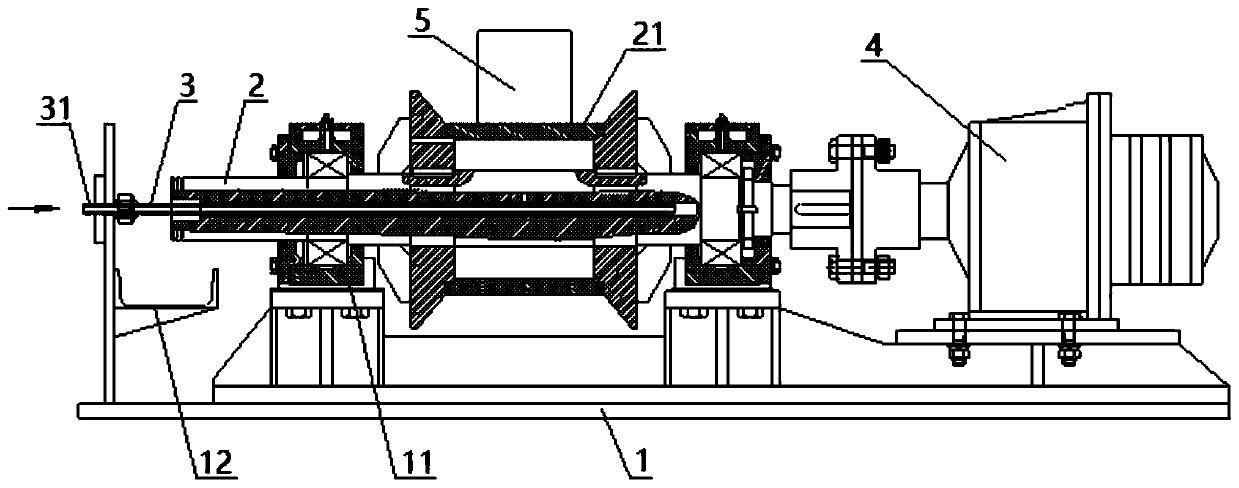

[0021] Please refer to the accompanying drawings, this embodiment provides a cooling structure for the ground roll of the heating furnace, including a base 1 and a tapping roll erected on the base 1, the tapping roll includes a hollow shaft 2 and is sleeved on the hollow shaft 2 An annular transport trough 21 is fixedly connected to the hollow shaft 2 for carrying and transporting the continuous casting billet 5 . The base 1 includes two bearing frames 11 , the bearing frames 11 are arranged symmetrically with respect to the transport groove 21 , and the hollow rotating shaft 2 is movably arranged on the bearing frames 11 . The hollow rotating shaft 2 is arranged horizontally. The hollow rotating shaft 2 includes a blind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com