Trigger device, trigger system and trigger method of pneumatic net gun of unmanned aerial vehicle

A technology of triggering device and unmanned aerial vehicle, which is applied to unmanned aerial vehicles, motor vehicles, compressed air guns, etc., can solve the problems of large volume of triggering device, large influence of ambient temperature, complicated operation, etc., and achieves light weight and reliability. High, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

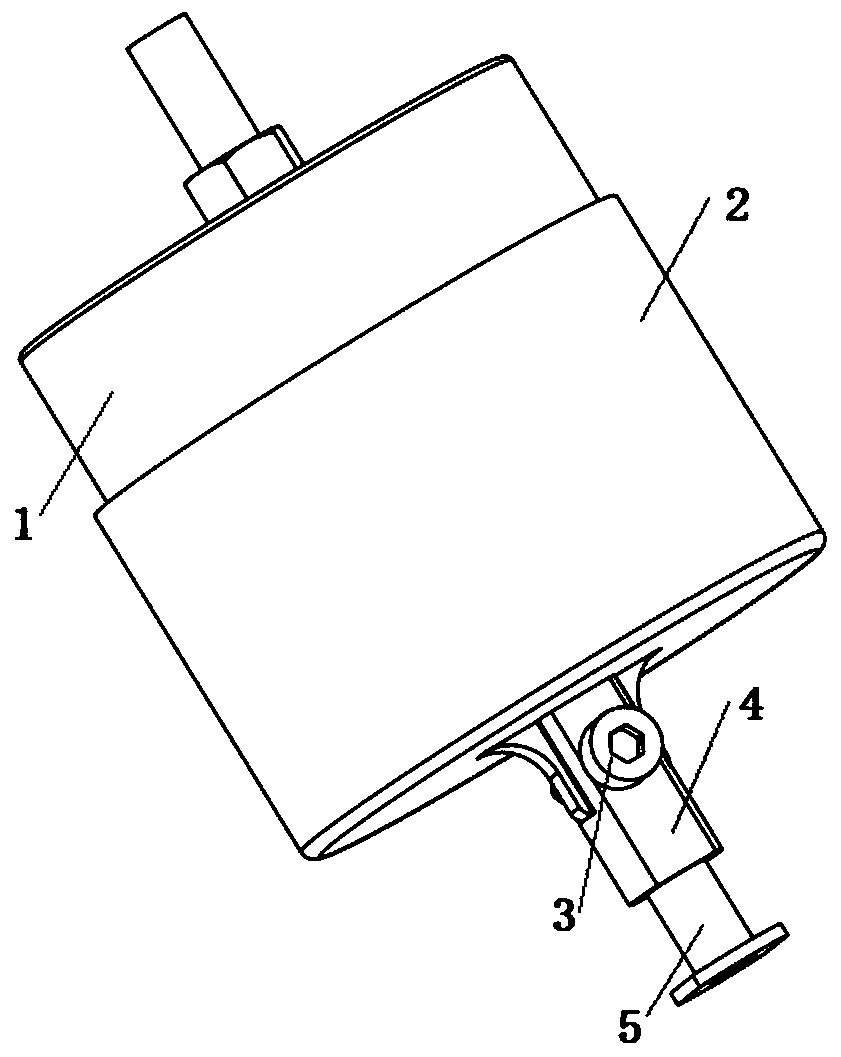

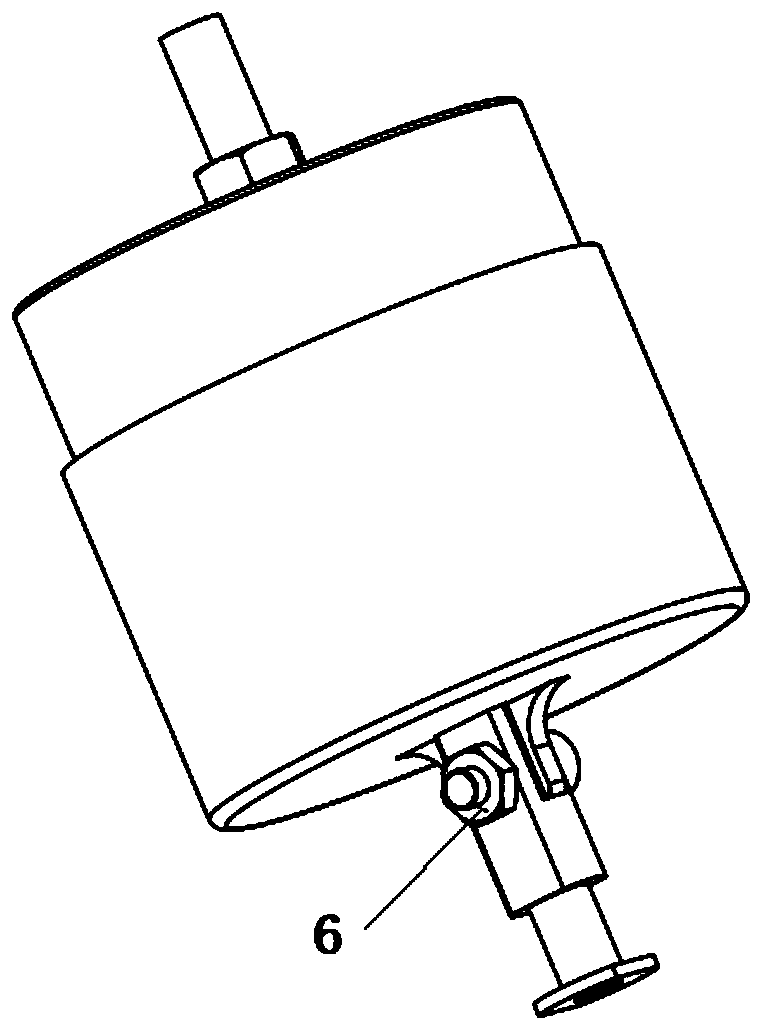

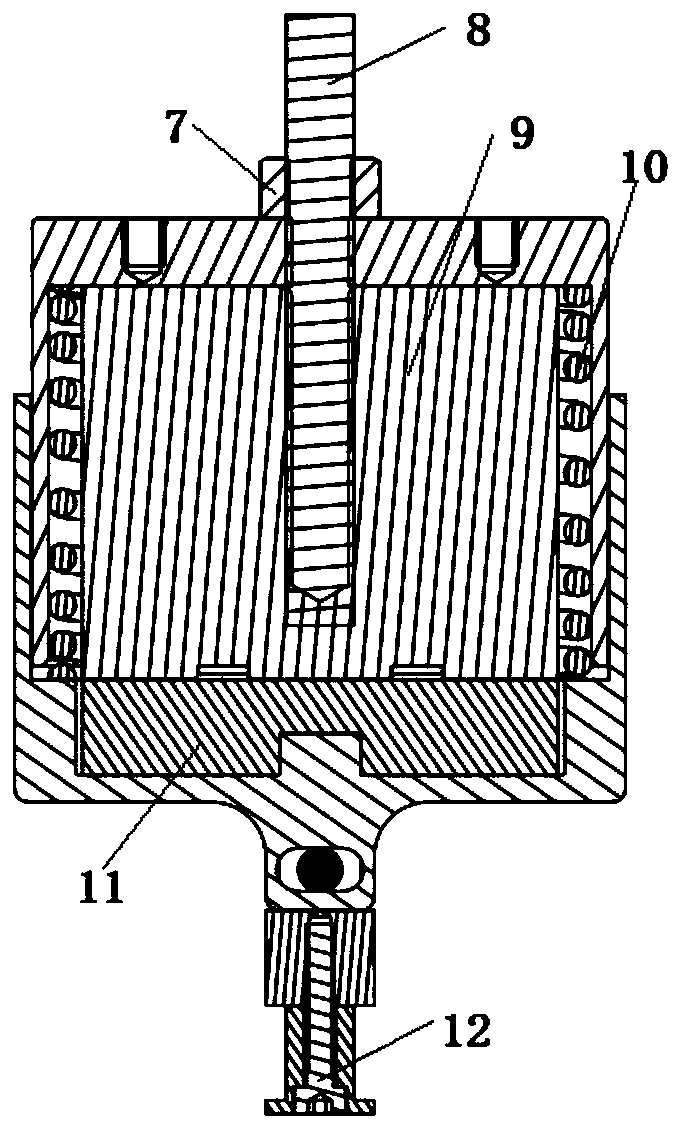

[0046] A specific embodiment of the present invention, such as Figure 1-Figure 4 As shown, a pneumatic net gun trigger device includes a top cover 1 , a bottom cover 2 , a de-energized electromagnet 9 , a suction cup 11 and a spring 10 . The de-energized electromagnet 9 is arranged in the top cover 1 , the suction cup 11 is arranged in the bottom cover 2 , and the spring 10 is compressed in the top cover 1 by the suction of the de-energized electromagnet 9 and the suction cup 11 . The spring 10 is used to apply elastic force to the bottom cover 2 to eject the bottom cover 2, so that the bottom cover 2 applies a trigger force to the pneumatic net gun 17.

[0047]Pneumatic net gun trigger device suction cup 11 is a cast iron material, and all the other part materials are aluminum alloys. Lost power type electromagnet 9 has magnetic force when not applying voltage at ordinary times, and magnetic force disappears when applying 24V voltage. Lost power type electromagnet 9 also c...

Embodiment 2

[0080] A pneumatic net gun trigger system such as Figure 5 , Figure 6 As shown, it includes the pneumatic net trigger device in Embodiment 1, and also includes an upper clamp 16 and a lower clamp 18; The clamps 18 are connected, and the pneumatic net gun 17 is clamped in the circular hole formed by the upper clamp 16 and the lower clamp 18 .

[0081] The upper clamp 16 is provided with a rectangular groove and a first semicircular groove, and the pneumatic net gun trigger device is arranged in the rectangular groove.

[0082] The center position of the top of the rectangular groove of the upper fixture 16 protrudes upwards to form a raised bar 1601. The center of the raised bar 1601 is provided with a first opening 1602. The upper end of the stud 8 passes through the first opening 1602, and passes through the stud 8 and the third The nut 15 installs the trigger device in the rectangular groove; the second nut 7 of the trigger device enters the protruding strip 1601, so tha...

Embodiment 3

[0087] A triggering method of a pneumatic net gun adopts the trigger system of a pneumatic net gun in embodiment 2, comprising the following steps:

[0088] Step 1. Install the trigger device;

[0089] Remove the trigger seat 5 from the trigger link 4, then remove the trigger link 4 from the bottom cover 2, and then fix the trigger device with the removed trigger link 4 and trigger seat 5 in the rectangular groove: stud 8 The upper end passes through the first opening 1602, the second nut 7 of the trigger device enters the protruding strip 1601, and the trigger device is installed in the rectangular groove through the stud 8 and the third nut 15; the fourth screw 14 passes through the second opening The hole 1603 is screwed into the threaded hole provided on the bottom surface of the top cover 1 to further fix the trigger device. Then use the first screw 3 and the first nut 6 to install the trigger link 4 on the bottom cover 2, finally pass the trigger seat 5 through the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com