Test platform and test method for electromagnetic acceleration counterweight impact compression buffer tube

A test platform and test method technology, applied in the direction of impact test, machine/structural component test, measuring device, etc., can solve the problems of poor initial velocity control of impact buffer tube, large installation space of drop weight test tower, poor attitude stability, etc. Achieve the effects of improving reliability, improving test safety, and stabilizing motion posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

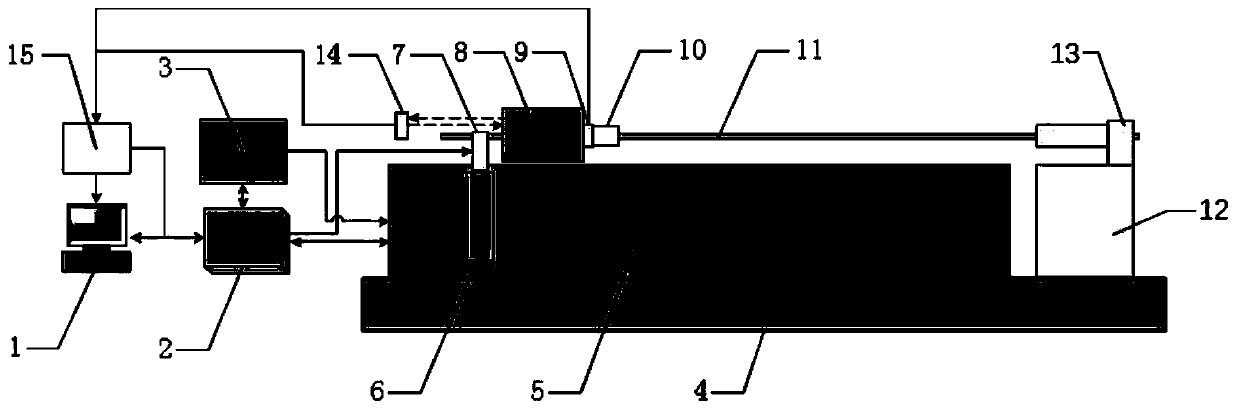

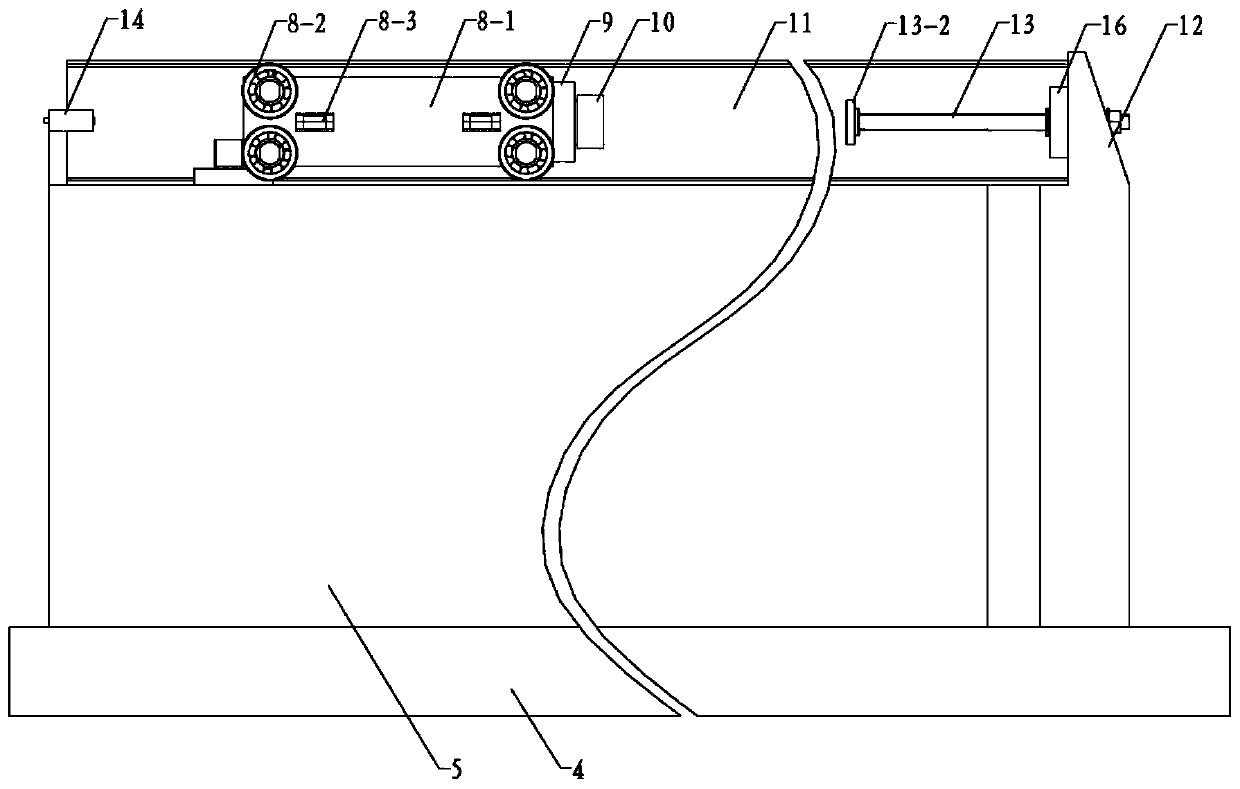

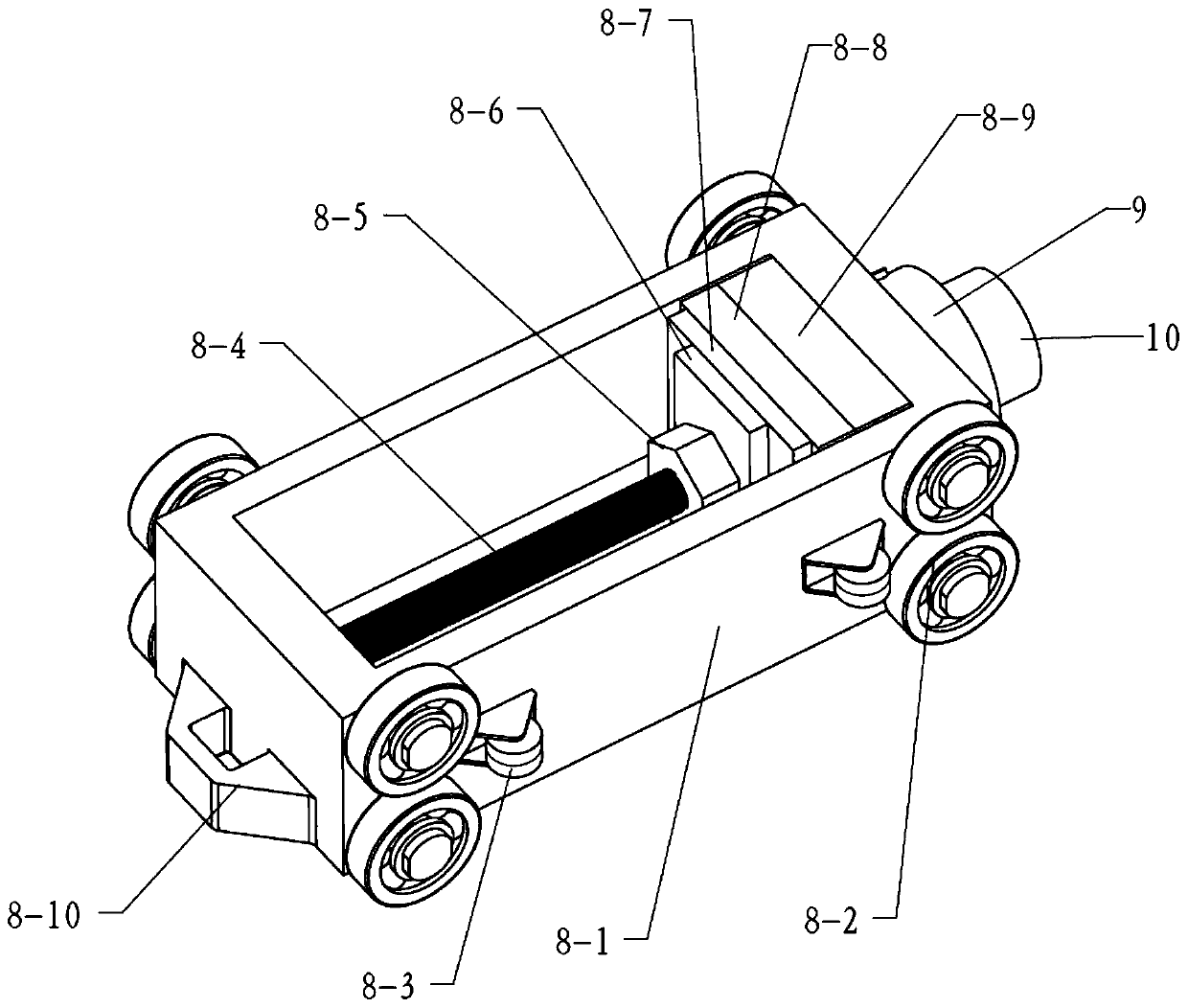

[0065] A specific embodiment of the present invention discloses a test platform for electromagnetic acceleration counterweight impact compression buffer tube, such as Figure 1 to Figure 2 As shown, it includes console 1, control system 2, power supply system 3, installation base 4, electromagnetic ejection system, lock release device 7, counterweight impact system, support guide device 11, buffer tube installation platform 12, displacement speed sensor 14 And data acquisition instrument 15, wherein, operating table 1 is used for carrying out parameter setting and sending operation order to test platform, and can display the signal that test platform collects in real time; Control system 2 is used for the control of test platform; Power supply system 3 Power is provided for the test platform; the electromagnetic catapult system is used to eject the counterweight impact system horizontally, so that the counterweight impact system slides horizontally under the support and constra...

Embodiment 2

[0094] Another specific embodiment of the present invention discloses a test method for electromagnetic acceleration counterweight impact compression buffer tube, based on the test platform for electromagnetic acceleration counterweight impact compression buffer tube in Embodiment 1, the test method includes the following steps:

[0095] Step 1: Assemble the test platform in Example 1.

[0096] Place the installation base 4 on the level ground, fix the electromagnetic catapult 5 and the buffer tube installation platform 12 on the installation base 4, install the support guide device 11, adjust the support guide device 11, so that the guide rail of the support guide device 11 is located Horizontal position; link mover 6, lock release device 7 and counterweight system 8.

[0097] Step 2: Install the buffer tube 13-3 to be tested.

[0098] Install and fix the buffer tube 13-3 on the buffer tube fixing device 13, the specific installation process is: insert the guide rod 13-2 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com