Method for measuring refractive index of material by irradiating edges and bottom surface of biprism

A technology of double prism and refractive index, which is applied in phase influence characteristic measurement, instruments, teaching models, etc. It can solve problems such as inability to measure, complicated adjustment of spectrometer and Abbe refractive index, etc., and achieve easy-to-understand measurement methods and simple calculations , the effect of clear measurement principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

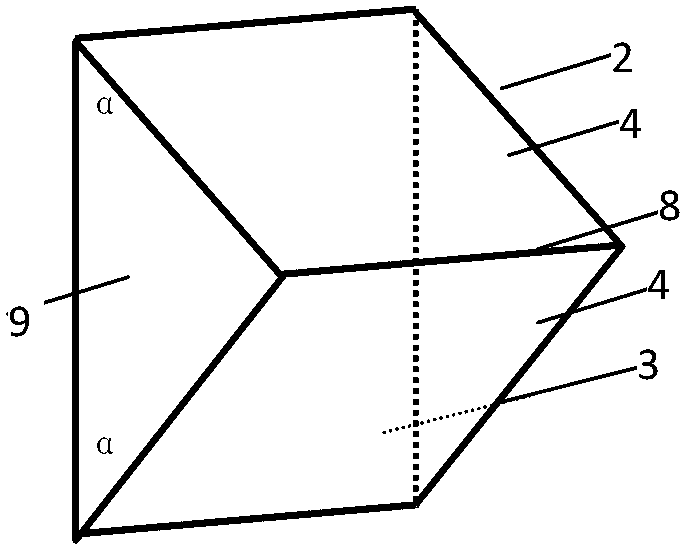

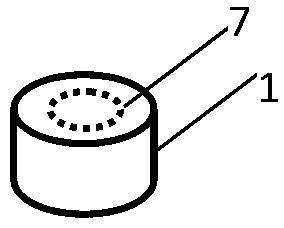

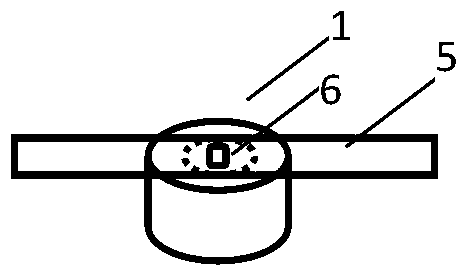

[0020] A method for measuring the refractive index of a material by illuminating the edges and bottom of a double prism, including two lasers 1 and a double prism 2, the double prism 2 includes two isosceles triangular faces and three rectangular faces, the largest rectangular face is the bottom face 3, in addition The two faces are facets 4, the side where the two facets 4 intersect is edge 8, and the isosceles triangle face is called side face 9 (the two isosceles triangle faces are parallel to each other and perpendicular to the three rectangular faces), the isosceles triangle The included angles between the two waists and the base are both α, that is, the included angle between the facet 4 and the bottom 3 is α; α is 0.5-1 o, so the sine value, tangent value and the radian value of the angle are approximately equal, the length of the double prism 2 is 40-60mm, and its thickness is 0.3-1mm, the length of the optical bench is generally more than 1000mm, so the thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com