A pole antenna bracket

An antenna bracket and rod antenna technology, which is applied to antennas, antenna supports/installation devices, antenna parts, etc., can solve the problems of unintuitive height adjustment, not easy to overlap, inconvenient to move, etc., so as to facilitate the overall movement , easy to operate, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

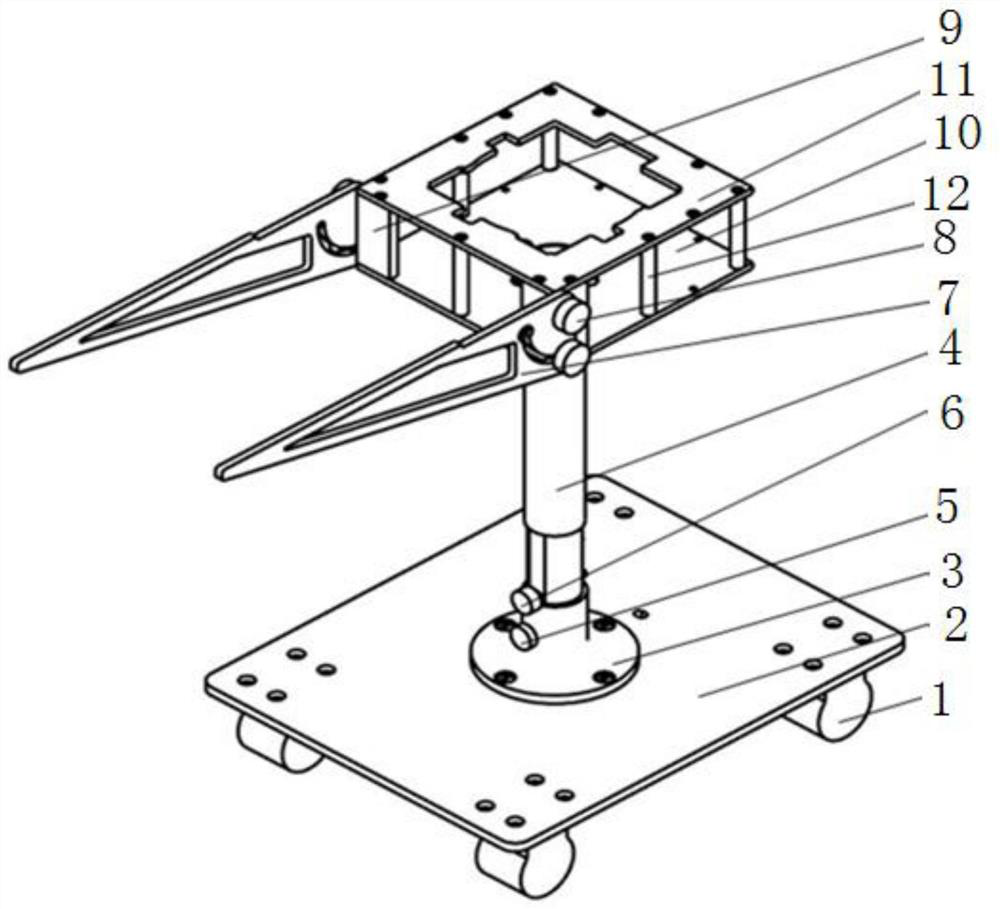

[0023] A rod antenna mount, see Figure 1 to Figure 4 , the antenna support includes a base 2, four casters 1 evenly distributed in a rectangular structure are installed under the base 2, and a cylindrical sleeve support 3 with an open upper end is installed on the base 2, see Figure 5 , the outer wall of the sleeve 4 is set as a stepped surface with the outer diameter of the lower part smaller than the outer diameter of the upper part, the outer wall of the lower part of the sleeve 4 is provided with a longitudinal plane, and the inner side wall of the sleeve support 3 is provided with a matching plane, the sleeve The lower part of 4 extends into the sleeve support 3, and the side wall of the sleeve support 3 is provided with a sleeve locking screw hole, and a sleeve locking screw 5 is arranged in the sleeve locking screw hole. The bottom of cylinder 4 is provided with transverse pin hole, see Figure 6 , the pin hole is provided with a bolt 6, and the pin hole is located a...

Embodiment 2

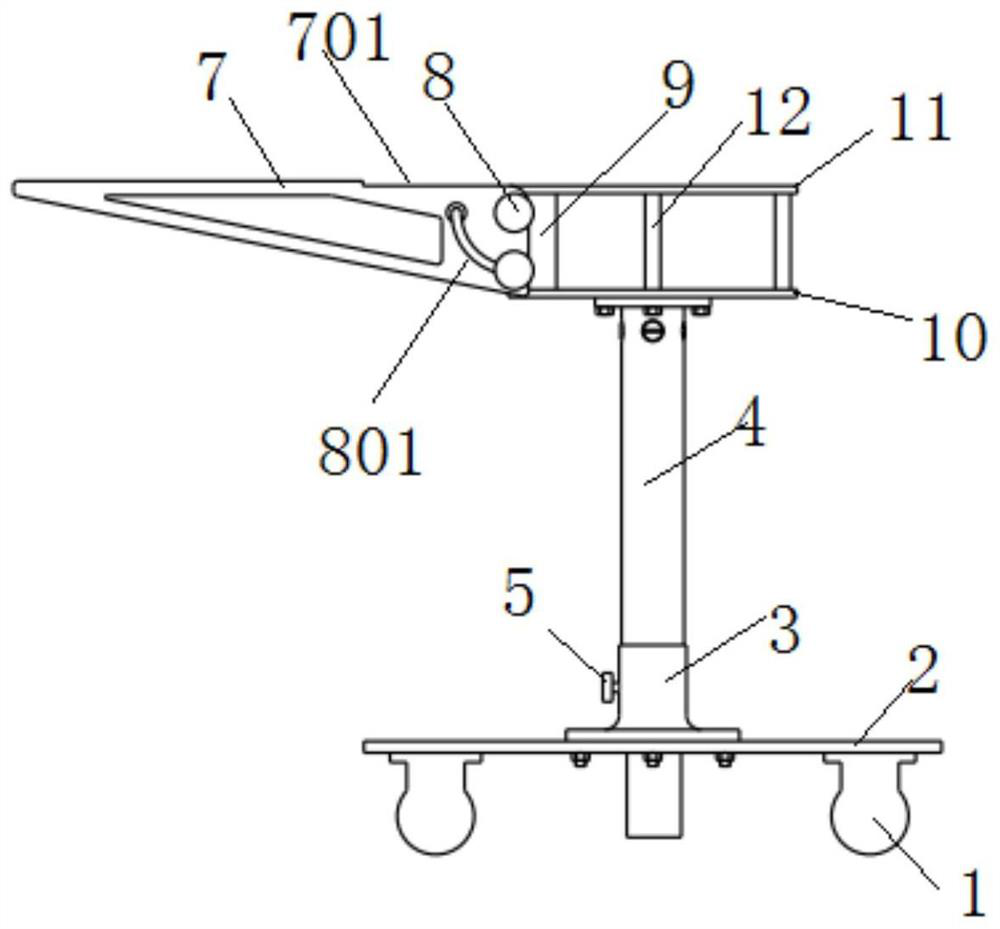

[0026] A rod antenna bracket, similar to Embodiment 1, the difference is that the lap support plate 7 is respectively connected to the outer side of the lap plate supporting fixed corner block 9 through two lap locking screws 8, one of which is lapped The locking screw 8 is located in the sliding groove 801 .

[0027] It may be further possible that, among the two overlapping locking screws 8 of the overlapping support plate 7 , the lower overlapping locking screw 8 is located in the slide groove 801 .

Embodiment 3

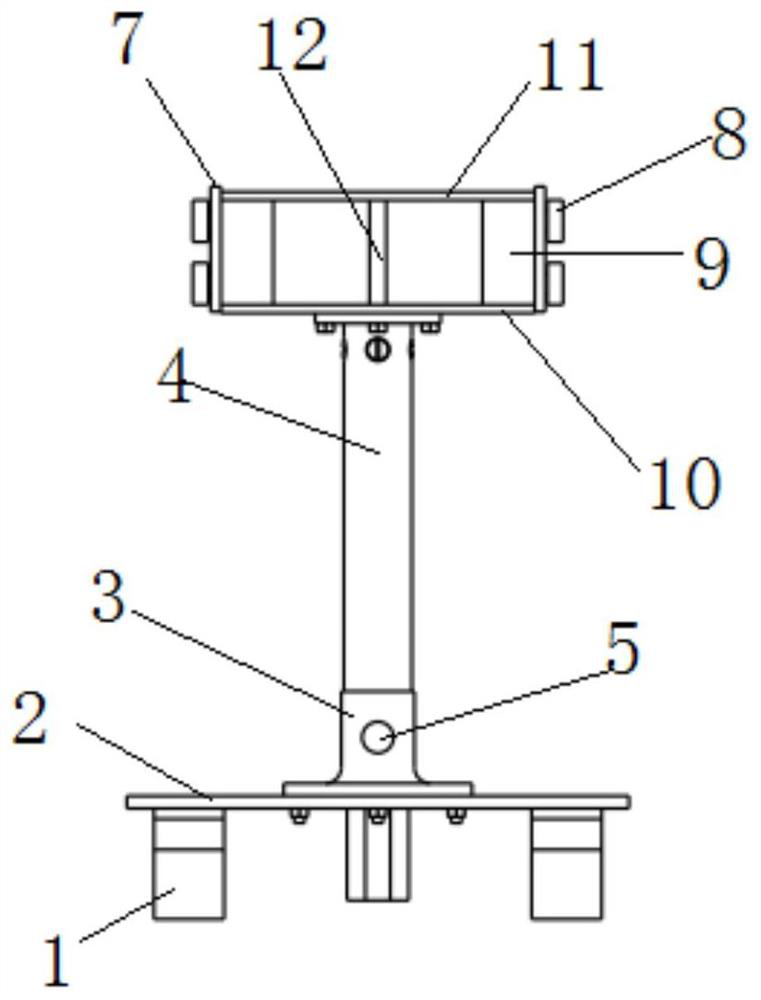

[0029] A rod antenna bracket, similar to Embodiment 1 or Embodiment 2, the difference is that the annular hole on the supporting plate 11 of the rod antenna is a cross-shaped hole.

[0030] Furthermore, the overlapping supporting plate 7 is a right-angled triangular plate whose top side is a horizontal side.

[0031] Furthermore, the right side of the overlapping support plate 7 is a vertical side.

[0032] Furthermore, hollow holes are provided on the overlapping support plate 7 . The hollow hole can also be a right triangle. And the side of the hollow hole is preferably parallel to the side of the adjacent overlapping support plate 7 .

[0033] Furthermore, the longitudinal centerlines of the base 2 , the sleeve support 3 , the sleeve 4 , the lower support plate 10 of the rod antenna and the upper support plate 11 of the rod antenna coincide.

[0034] The rod antenna support, as a height adjustment device suitable for old and new standards, can be adjusted in one step; an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com