Electric push rod capable of only pushing but not pulling

An electric push rod and screw technology, applied in the field of mechanical device transmission, can solve the problems of high risk, low safety performance, easy to be pinched, etc., and achieve the effects of convenient operation, improved safety performance and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

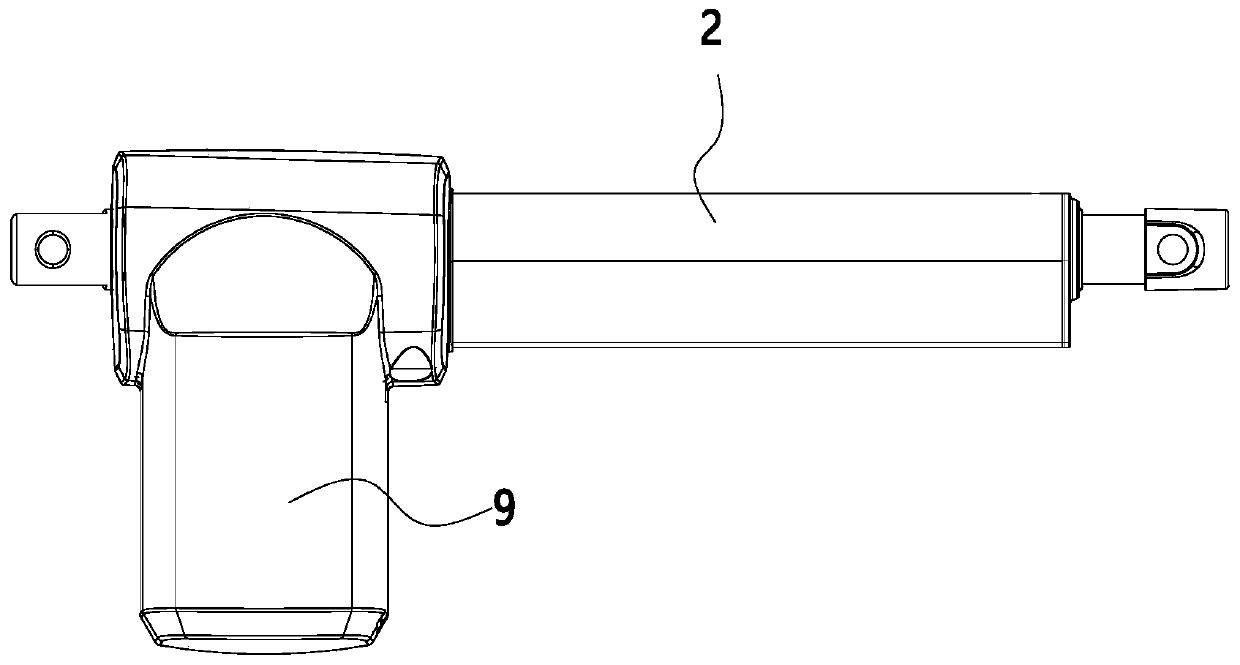

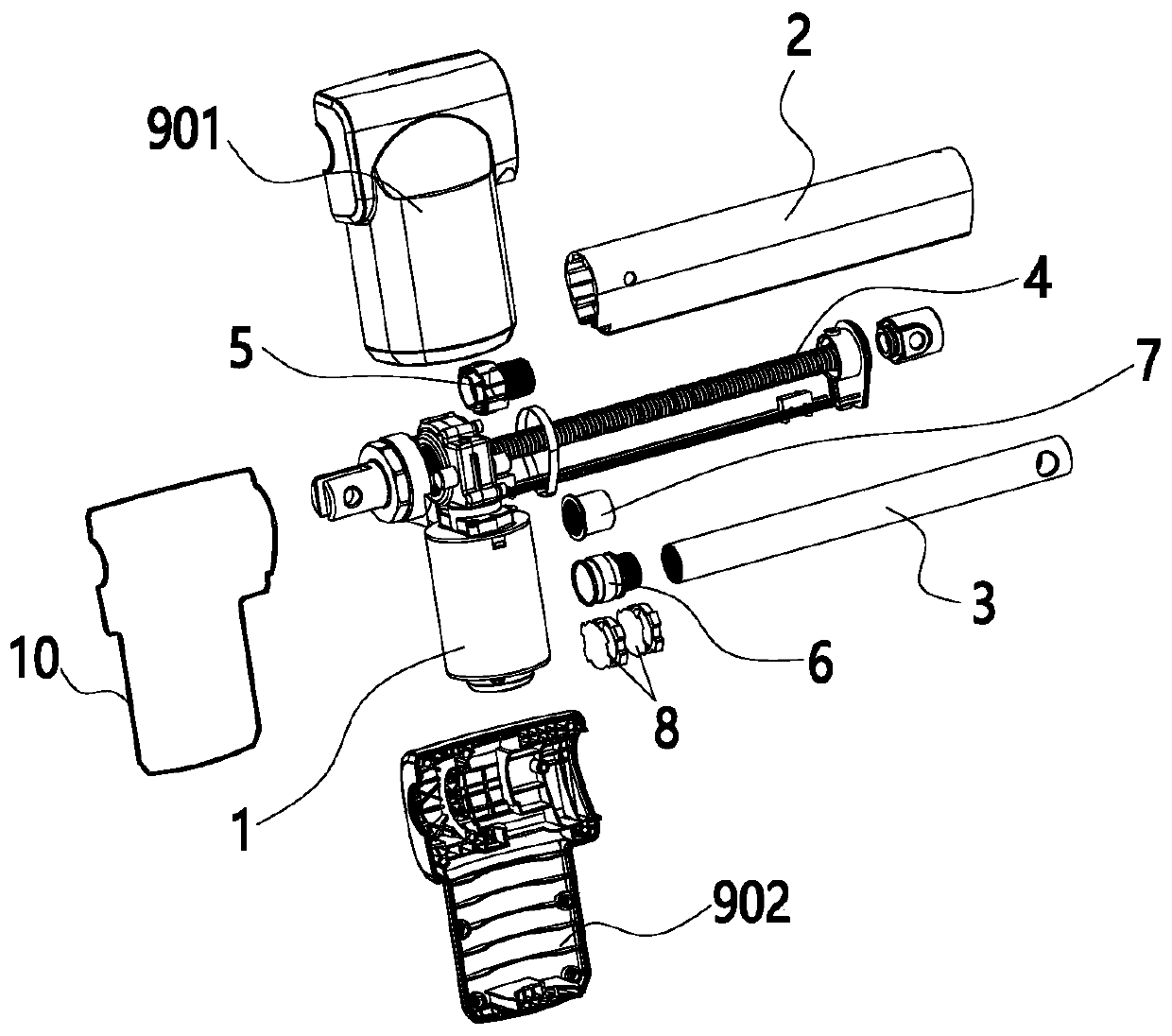

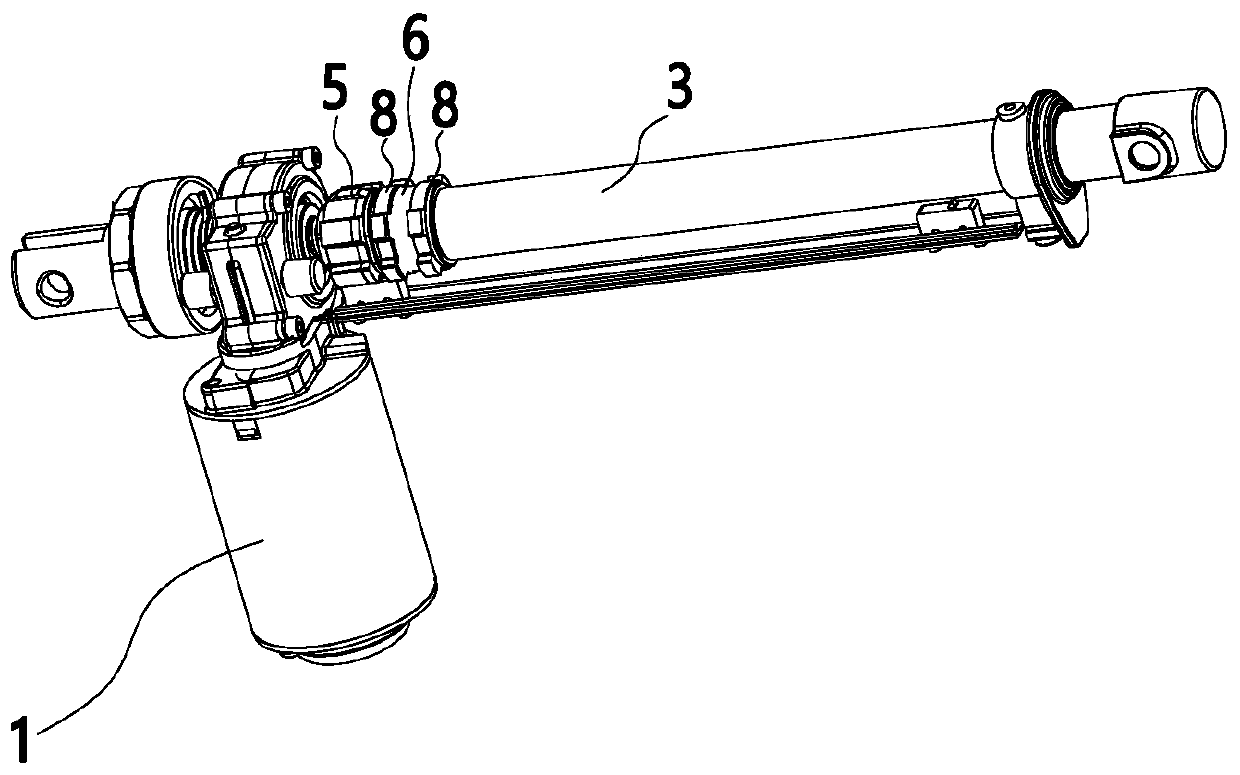

[0039] Such as Figure 1 to Figure 12 As shown, an electric push rod that only pushes but does not pull, the electric push rod includes a drive motor 1, an outer tube 2 fixedly connected to the drive motor 1 and an inner tube 3 sleeved in the outer tube 2, and the outer tube 2 is also provided with Driven by the drive motor 1, the screw 4 rotates and the nut 5 is sleeved on the screw 4 and moves along the axial direction of the screw 4. The drive motor 1 and the screw 4 are connected by transmission, and the inner tube 3 is provided with a coupling Set of 6, such as Image 6 As shown, the coupling sleeve 6 includes a first coupling portion 601 fixedly connected to the inner tube 3 , a second coupling portion 602 for slidingly sleeved on the nut 5 and a step connecting the first coupling portion 601 and the second coupling portion 602 part 603 , the coupling sleeve 6 bears the axial force on the nut 5 through the step part 603 .

[0040] When the drive motor 1 rotates forward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com