High-temperature extrusion molding machine

A molding machine, high temperature technology, applied in the field of plastic processing, can solve the problems of poor heating effect, long mixing time, uneven heating of barrel raw materials, etc., to achieve the effect of reducing mixing time, uniform heating, and improving extrusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

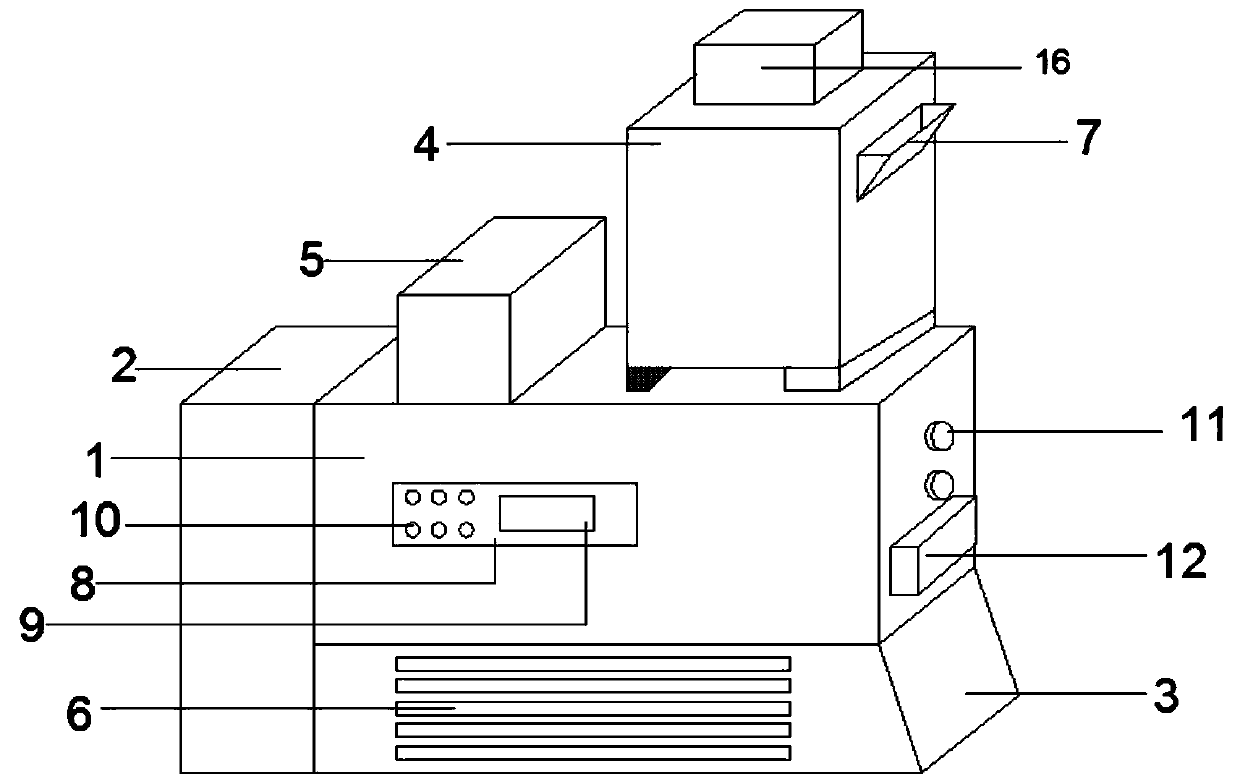

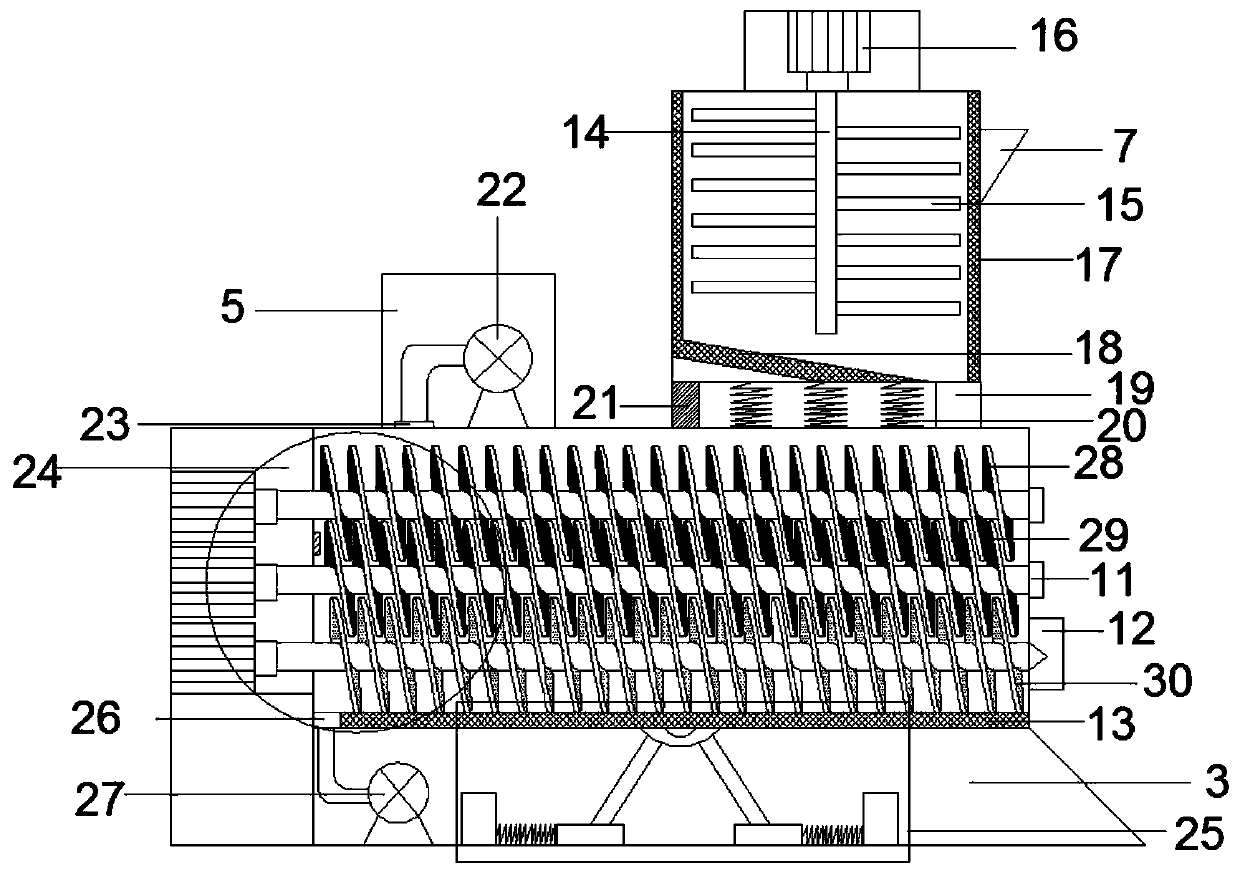

[0031] refer to Figure 1-2 and Figure 5-6, a high-temperature extrusion molding machine, comprising an extrusion box 1, a power box 2 arranged on one side of the extrusion box 1, a feed box 4 at the top of the extrusion box 1 and a base 3 at the bottom of the extrusion box 1, said Stirring motor 16 is arranged on the top of feeding box 4, and stirring shaft 14 is arranged inside feeding box 4, and described stirring shaft 14 is connected with output shaft of stirring motor 16, and described stirring shaft 14 both sides are staggered to be provided with stirring blade 15, The upper end of one side of the feed box 4 is provided with a feed inlet 7, and a layer of electric heating layer 17 is arranged on the inner side wall of the feed box 4, and a feed inlet 19 is arranged on one side of the bottom of the feed box 4, and the feed inlet 19 is connected to the The extrusion box 1 is connected, and the other side of the bottom of the feeding box 4 is provided with a support plat...

Embodiment 2

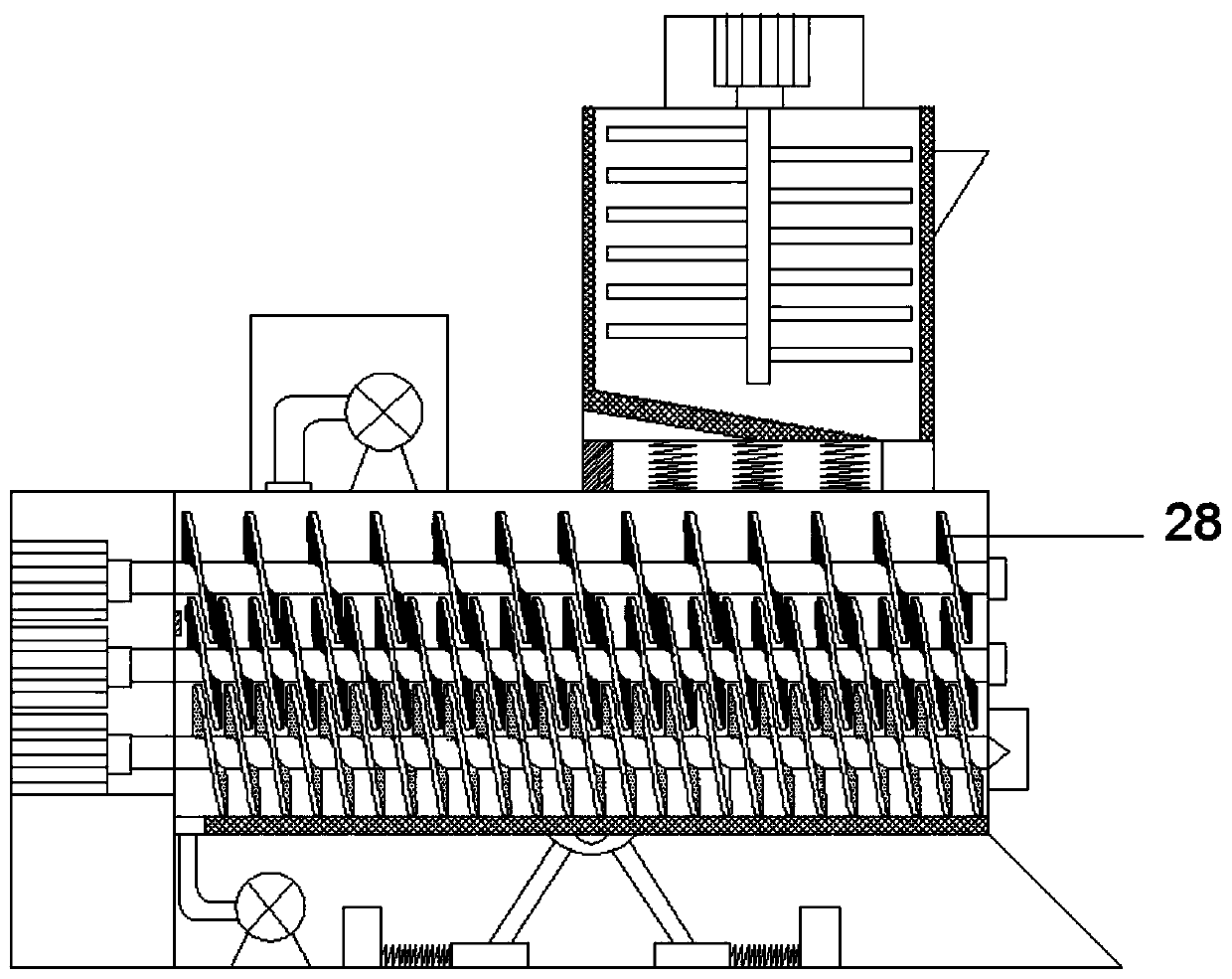

[0038] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the number of helical blades of the first helical blade 28 is half of that of the second helical blade 29, and the first helical blades 28 and the second helical blades 29 are arranged alternately. . It can effectively make the masterbatch fall into the second screw blade 29 and the third screw blade 30 below as soon as possible, so as to speed up the extrusion efficiency, reduce the use of heating wires, and save energy.

Embodiment 3

[0040] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bottom end of the power box 2 is provided with a No. 1 motor 33, and the third rotating shaft 31 and the first rotating shaft 40 extend through the extrusion box 1 into the power box 2. , is rotationally connected with the side wall of the power box 2, the output shaft of the No. 1 motor 33 is rotationally connected with the third rotating shaft 31 and the first rotating shaft 40 through a rotating belt 34, and the second rotating shaft 39 is connected with the No. 2 motor 32 in the power box 2 The output shaft is fixedly connected, and the No. 2 motor 32 and the No. 1 motor 33 are electrically connected with the control button 10 . The third rotating shaft 31 and the first rotating shaft 40 can be rotated synchronously, and the rotation speed of the second rotating shaft 39 and the third rotating shaft 31 and the first rotating shaft 40 can be adjusted conveniently, so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com