Garbage treatment device

A technology of a garbage disposal device and a flat plate, applied in the direction of presses, manufacturing tools, etc., can solve the problems of unavoidable landfill leachate, pollution, and inability to fully extrude landfill leachate, and achieve the effect of avoiding pollution of groundwater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

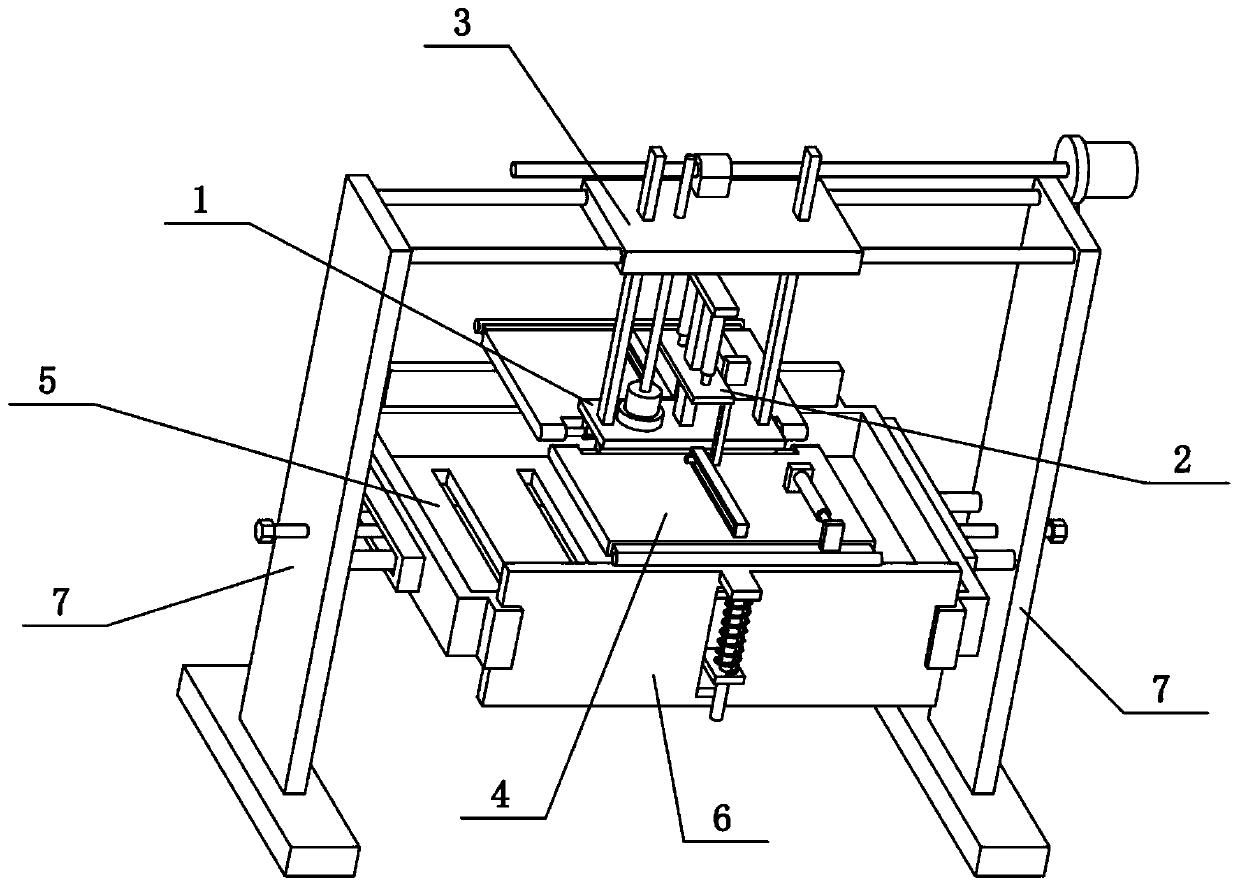

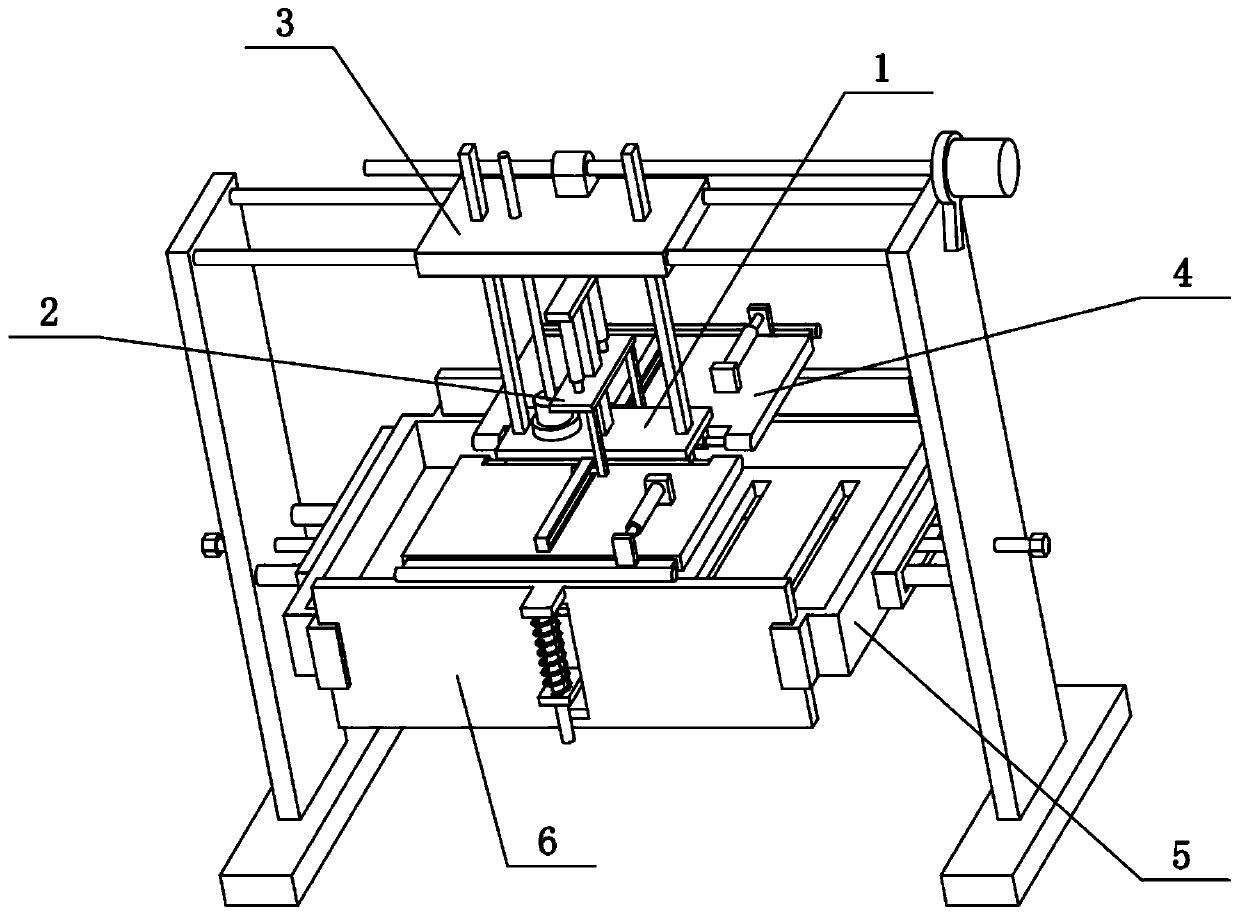

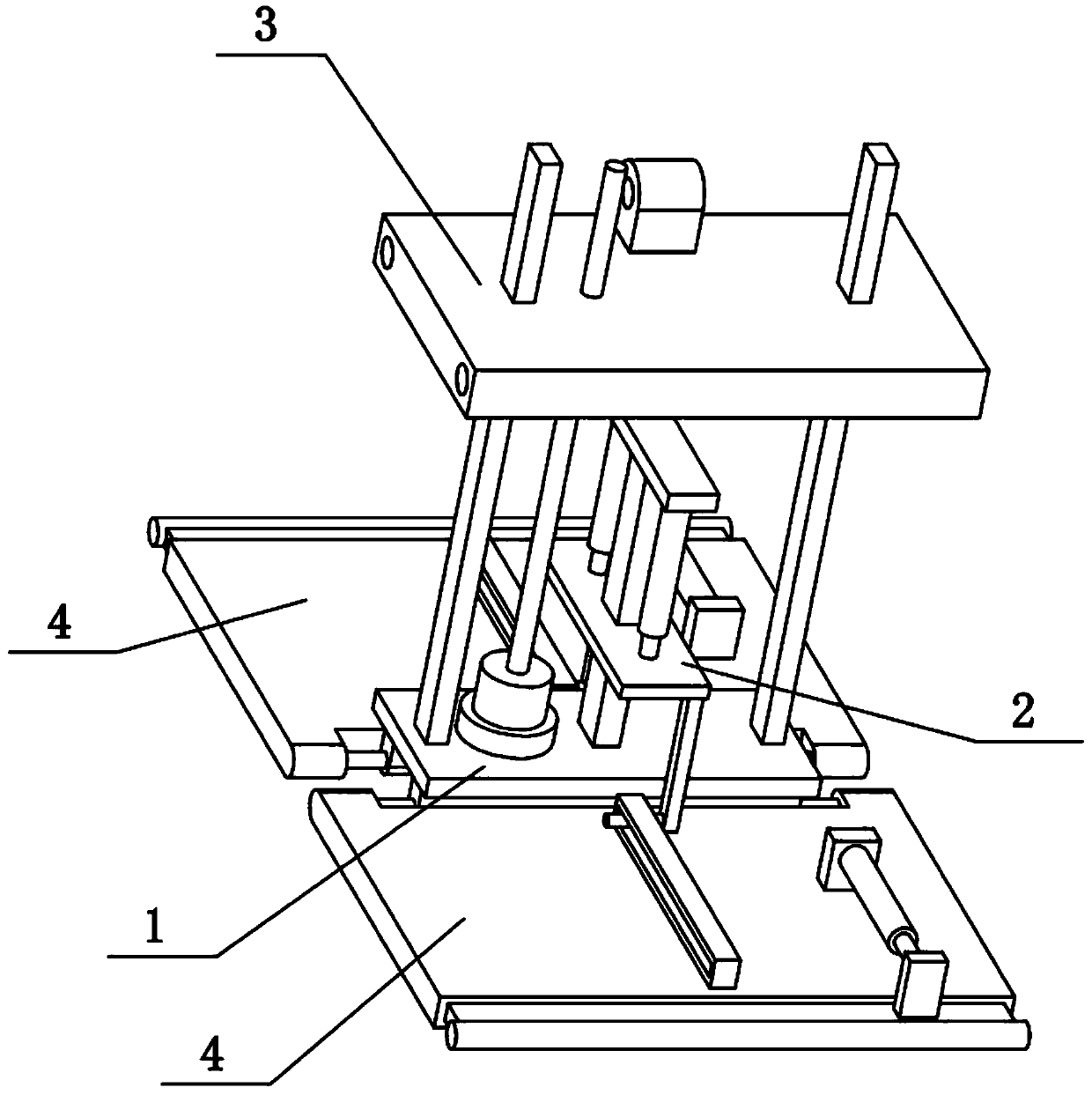

[0028] Combine below Figure 1-9 Describe this embodiment, the present invention relates to the field of garbage disposal, more specifically a garbage disposal device, including a flat plate 1, a convex strip 101, a top plate 104, an electric telescopic rod I105, a middle rod 106, a lifting plate 2, and a connecting strip 201 , sliding cylinder 202, pressing plate 4, major axis 401, sliding hole rod 402 and sliding hole 403, the present invention can fully squeeze out the landfill leachate in the rubbish, avoiding landfill leachate from polluting groundwater.

[0029] The front and rear ends of the lower side of the flat panel 1 are fixedly connected with convex strips 101, the upper center of the flat panel 1 is fixedly connected with a middle rod 106, and the middle rod 106 is slidably connected with a lifting plate 2, and the front and rear sides of the lower side of the lifting plate 2 Both ends are fixedly connected with connecting strips 201, the lower ends of the two co...

specific Embodiment approach 2

[0031] Combine below Figure 1-9 To illustrate this embodiment, the garbage disposal device also includes an electric telescopic rod II404, a convex seat 405 and a telescopic plate 406, the two pressure plates 4 are hollow structures, and the outer sides of the two pressure plates 4 are slidingly connected with the telescopic plate 406, two The upper side of the telescopic plate 406 is fixedly connected with the convex seat 405, the upper side of the two pressing plates 4 is fixedly connected with the electric telescopic rod II404, and the outer ends of the two electric telescopic rods II404 are fixedly connected with the two convex seats 405 respectively. When performing the operation of "making the angle between the two pressure plates 4 smaller", the two electric telescopic rods II404 are extended simultaneously, so that the two telescopic plates 406 are stretched out, and the area of the two pressure plates 4 is enlarged, which is convenient for garbage disposal. The lef...

specific Embodiment approach 3

[0033] Combine below Figure 1-9 Referring to this embodiment, the garbage disposal device further includes a cylindrical edge 407, and the outer ends of the two telescopic plates 406 are both provided with a cylindrical edge 407. The cylindrical edge 407 reduces the frictional force on the lower part of the pressing plate 4 to prevent the two pressing plates 4 from being stuck when clamping the garbage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com