Process and device for treating black liquor

A technology of black liquor and black liquor tank, which is applied in the field of black liquor processing technology and its devices, can solve the problems of environmental damage, high cost of chemicals, high COD and salinity, and achieve the effects of lightening load, reducing burden and reducing COD.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

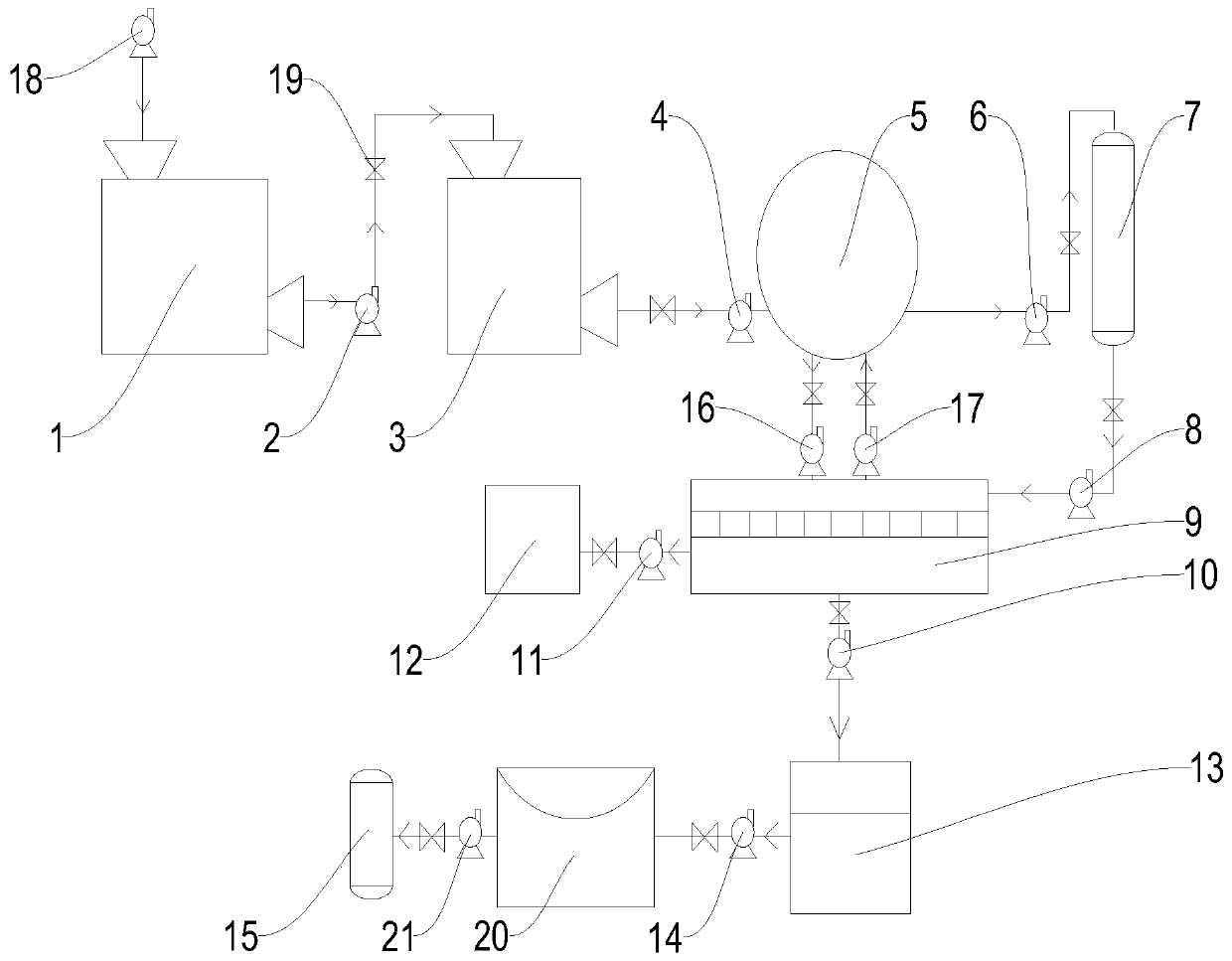

[0039] Such as figure 1 Shown, a kind of process of processing black liquor comprises the following steps:

[0040] A, raw material waste liquid in 1000kg papermaking process enters described first black liquor squeezer 1 and described second black liquor squeezer 3 successively through described raw material liquid feeding pump 18 and squeezes to obtain 500kg dilute black liquor ;

[0041]B, the 500kg dilute black liquor in step A is passed in the described sedimentation tank 5 by described dilute black liquor feeding pump 4, then in the described sedimentation tank 5, add the calcium hydroxide of 80g, generate calcium carbonate solid Precipitation, after 3h of precipitation, the 230kg supernatant of the settling tank 5 is passed through the second delivery pump 6 into the desulfurization tower 7 as a desulfurizer to obtain 184kg desulfurization waste liquid;

[0042] C, the 184kg desulfurization waste liquid that obtains in the step B is passed in the described filter pres...

Embodiment 2

[0047] The difference with Example 1 is that the calcium carbonate solid precipitation at the bottom of the settling tank 5 is passed into the filter press 9 by the precipitation feed pump 16 to obtain calcium carbonate solids and clear liquid, and the filter press The clear liquid in 9 is passed in the described settling tank 5 by the reflux pump 17, and the calcium carbonate solid is passed in the collection tank 12 by the fourth delivery pump 11. The method realizes the full treatment of raw material waste liquid and the collection of calcium carbonate in the papermaking process, and realizes waste utilization.

Embodiment 3

[0049] Such as figure 1 Shown, a kind of process of processing black liquor comprises the following steps:

[0050] A, raw material waste liquid in 1000kg papermaking process enters described first black liquor squeezer 1 and described second black liquor squeezer 3 successively through described raw material liquid feeding pump 18 and squeezes to obtain 510kg dilute black liquor ;

[0051] B, the 510kg dilute black liquor in step A is passed in the described sedimentation tank 5 by described dilute black liquor feeding pump 4, then in the described sedimentation tank 5, add the calcium hydroxide of 82g, generate calcium carbonate solid Precipitation, after 3h of precipitation, the 225kg supernatant of the settling tank 5 is passed into the desulfurization tower 7 through the second delivery pump 6 as a desulfurizer to obtain 174kg desulfurization waste liquid;

[0052] C, the 174kg desulfurization waste liquid that obtains in the step B is passed in the described filter pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com