Loose fiber dehydration process

A bulk fiber and process technology, which is applied in the field of liquid-phase continuous processing of textile materials, can solve the problems of bouncing on conveyor belts and rolls, physical properties of loose fibers are reduced, and become weak.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

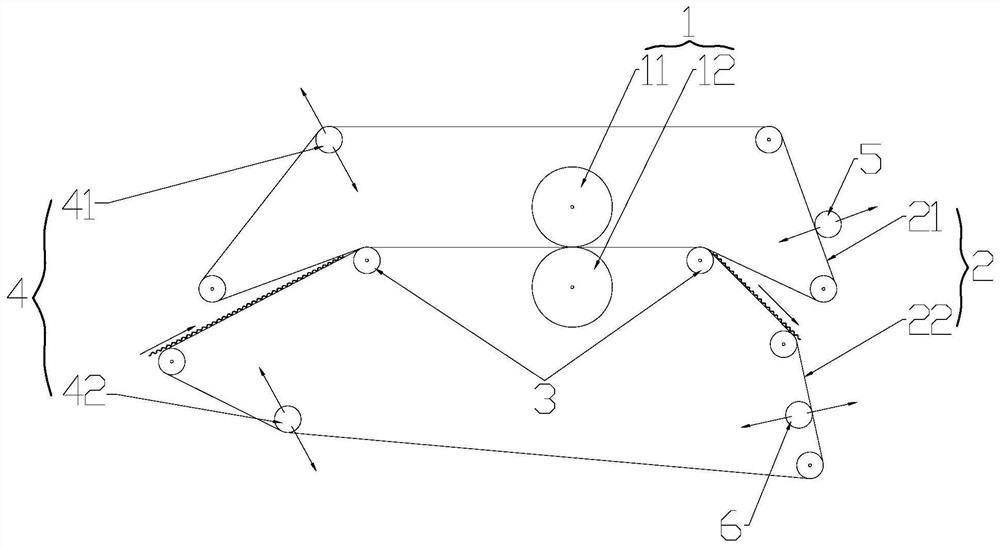

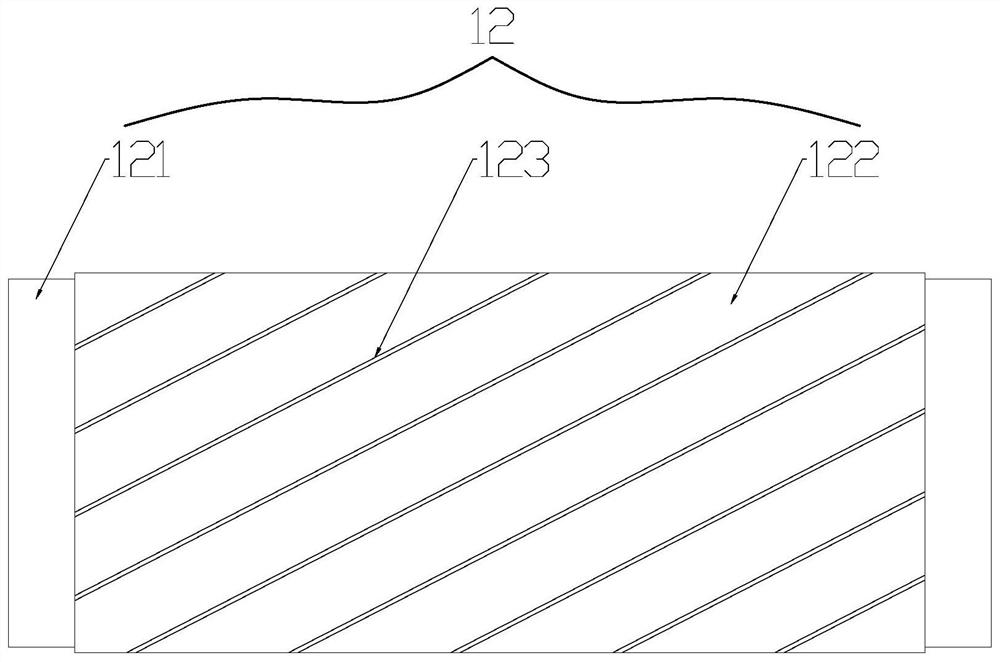

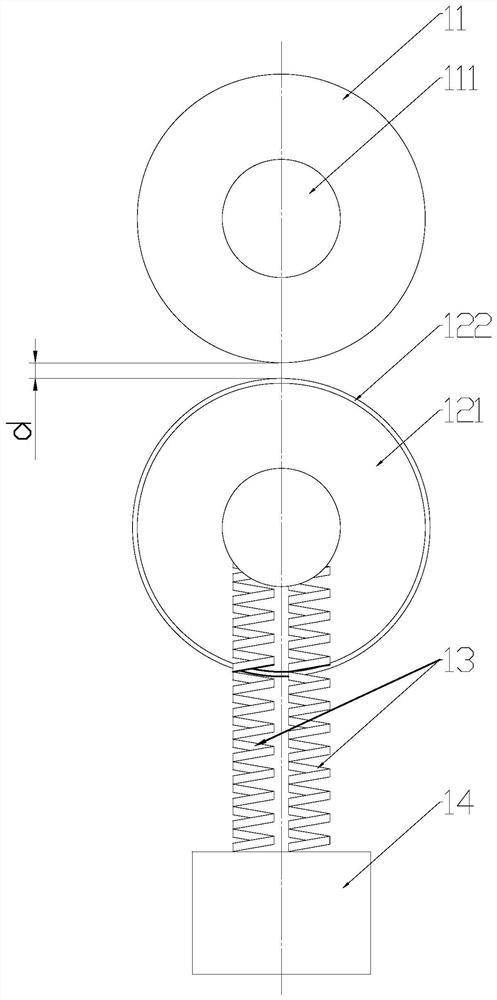

[0023]A loose fiber dehydration process, combiningfigure 1 , The loose fibers to be treated are transported by the guide belt 2, and the water is squeezed out when passing between the pair of rollers 1. The guide belt 2 is provided with hydrophobic holes, and the squeezed water is discharged through the hydrophobic holes. Each pair of rollers 1 Including the upper roller 11 and the lower roller 12, the roller 1 is driven by an oil cylinder (not shown in the figure). At least one of the upper roller 11 and the lower roller 12 is equipped with a buffer device (spring in the figure) 13, and the surface pressure of the loose fiber reaches a certain level. In the range, the buffer device 13 deforms to drive the corresponding roll 1 (upper roll 11 and / or lower roll 12) to move, and pull the corresponding upper roll 11 and / or lower roll 12 to move until the distance between the two is appropriate.

[0024]In the dewatering process of loose fibers, especially when the conveyor belt is used for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com