A kind of anti-corrosion technology of stainless steel pipe

A stainless steel tube and process technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve problems such as affecting process effect and poor degreasing effect, to ensure treatment quality, improve degreasing effect, and improve anti-corrosion effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

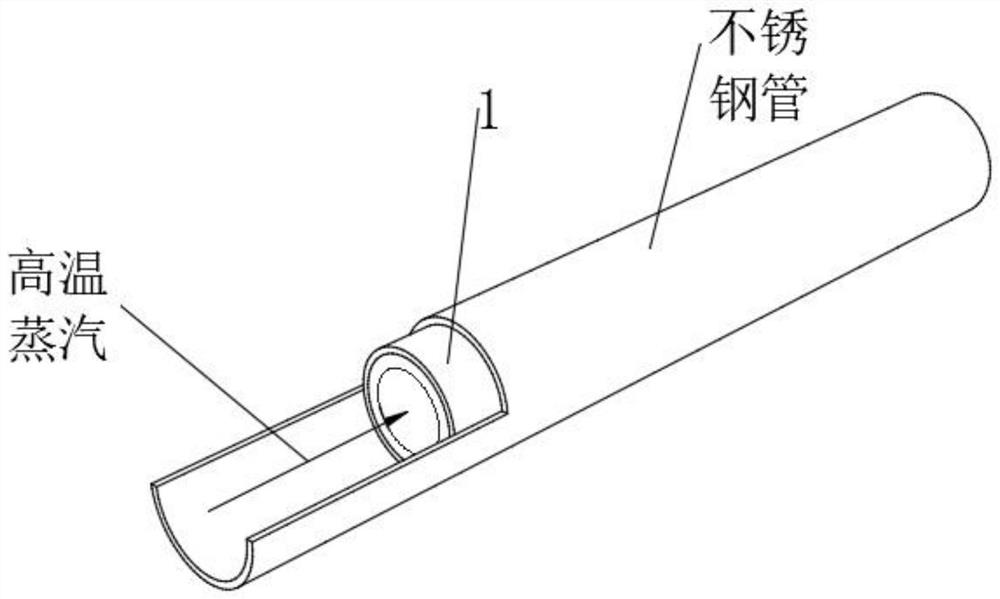

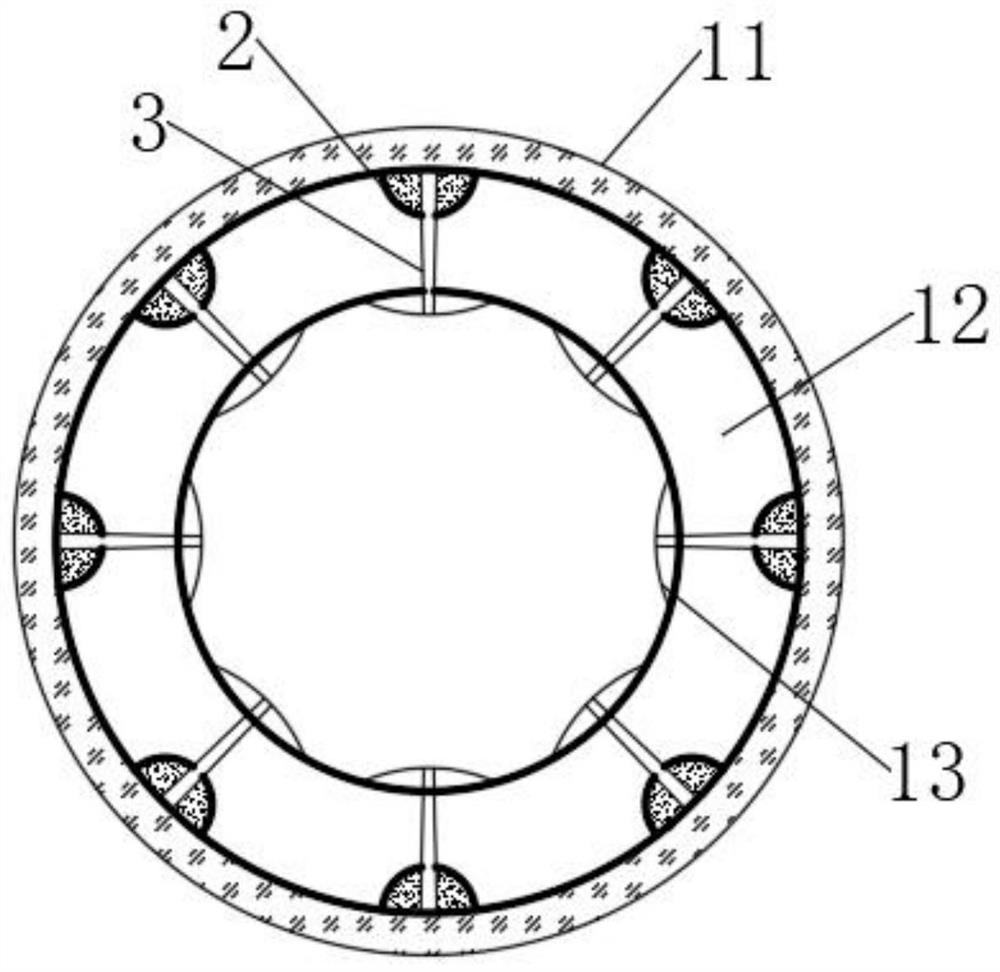

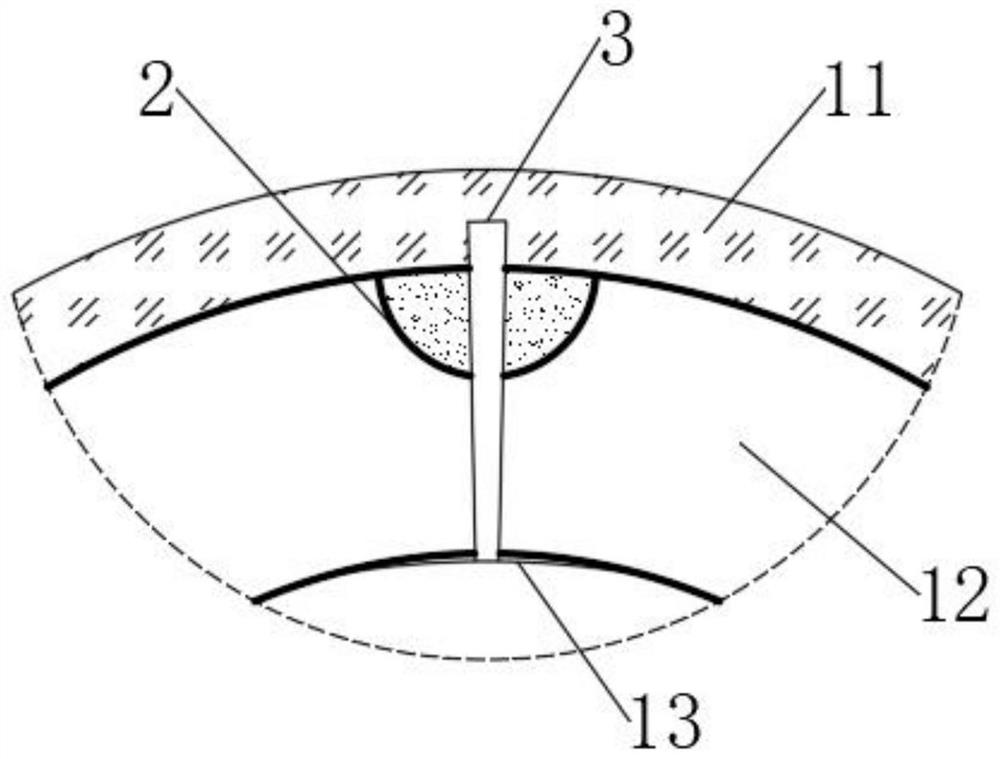

[0047] see figure 1 , a stainless steel pipe anticorrosion process, comprising the following steps:

[0048] S1. Take the degreasing ring 1 and put it in the stainless steel pipe, and then pass the high-temperature steam flow inward;

[0049] S2. Change the flow rate of the steam flow, push the degreasing ring 1 to migrate at high speed, and stop degreasing and degreasing the stainless steel pipe wall at low speed;

[0050] S3. After the degreasing ring 1 is removed from the stainless steel pipe, it is polished to remove the oxide film, and then cleaned and dried;

[0051] S4, sandblasting the stainless steel pipe, then pickling passivation and washing and drying;

[0052] S5. Using a vacuum coating machine to coat the stainless steel tube with a chromium film, and then apply an antirust agent and dry it.

[0053] The temperature of the high-temperature steam is 80-85 degrees Celsius, which can not only provide power, but also heat to improve the degreasing effect.

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com