Automatic tray placing device

A kind of equipment and automatic technology, applied in the direction of unstacking of objects, stacking of objects, conveyor objects, etc., can solve the problems of manpower consumption, low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of tight and smooth action coordination and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

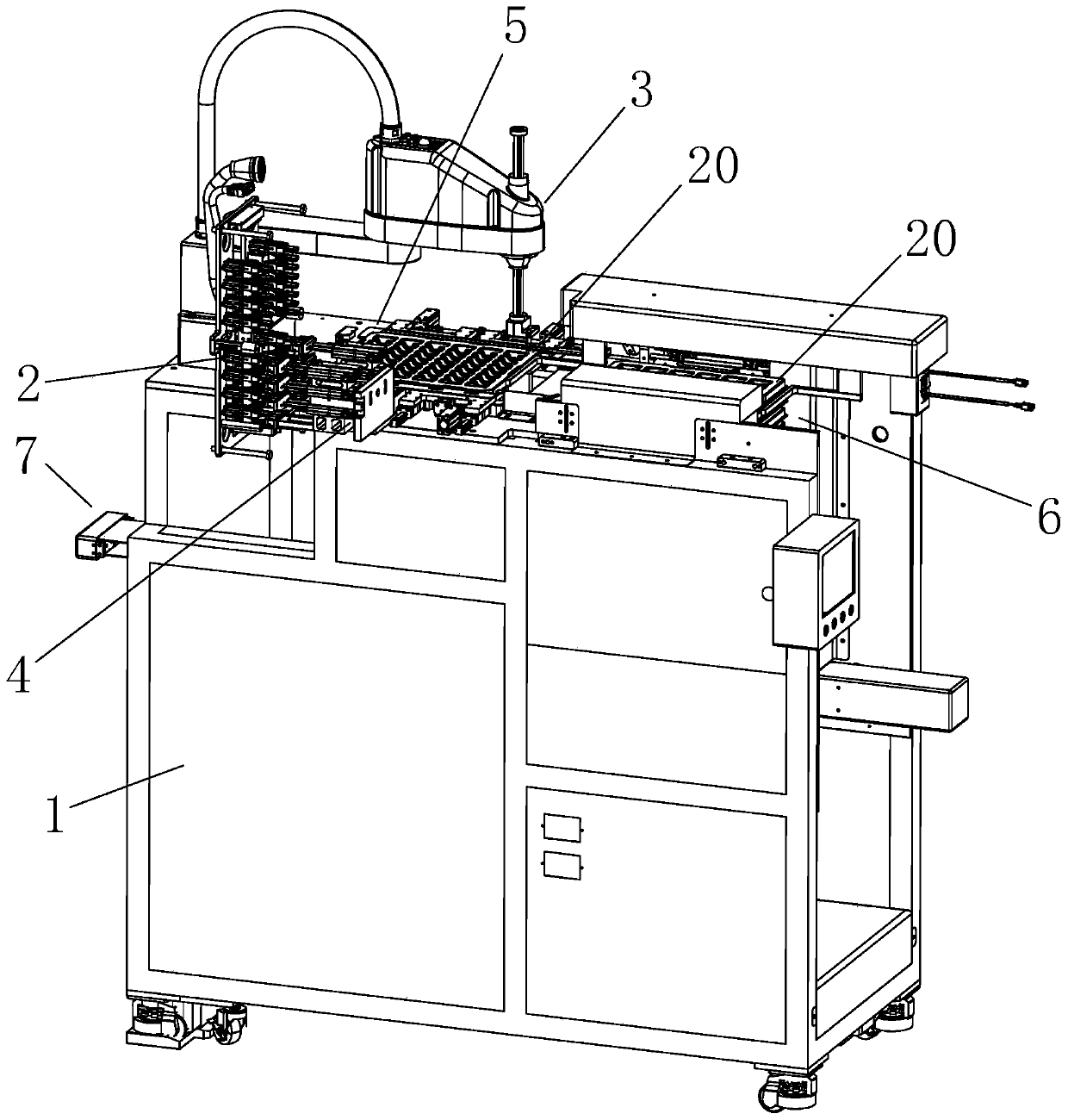

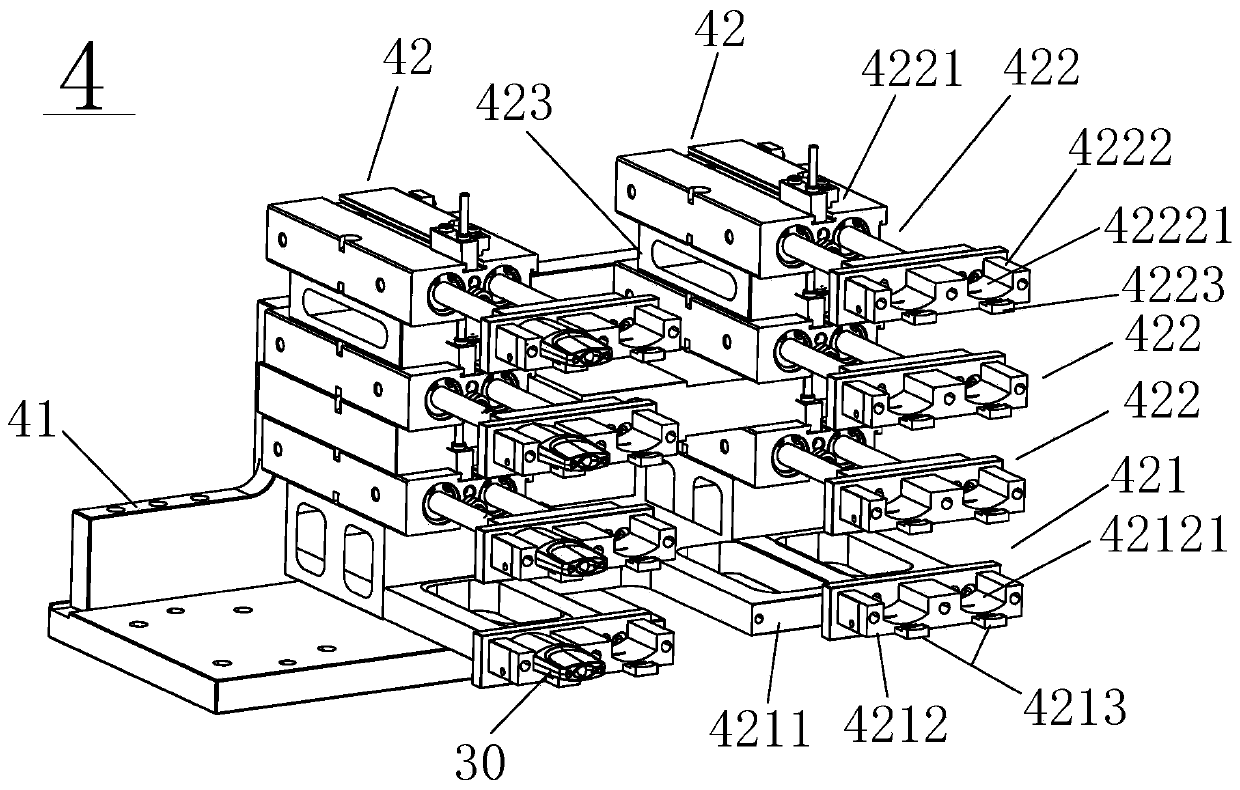

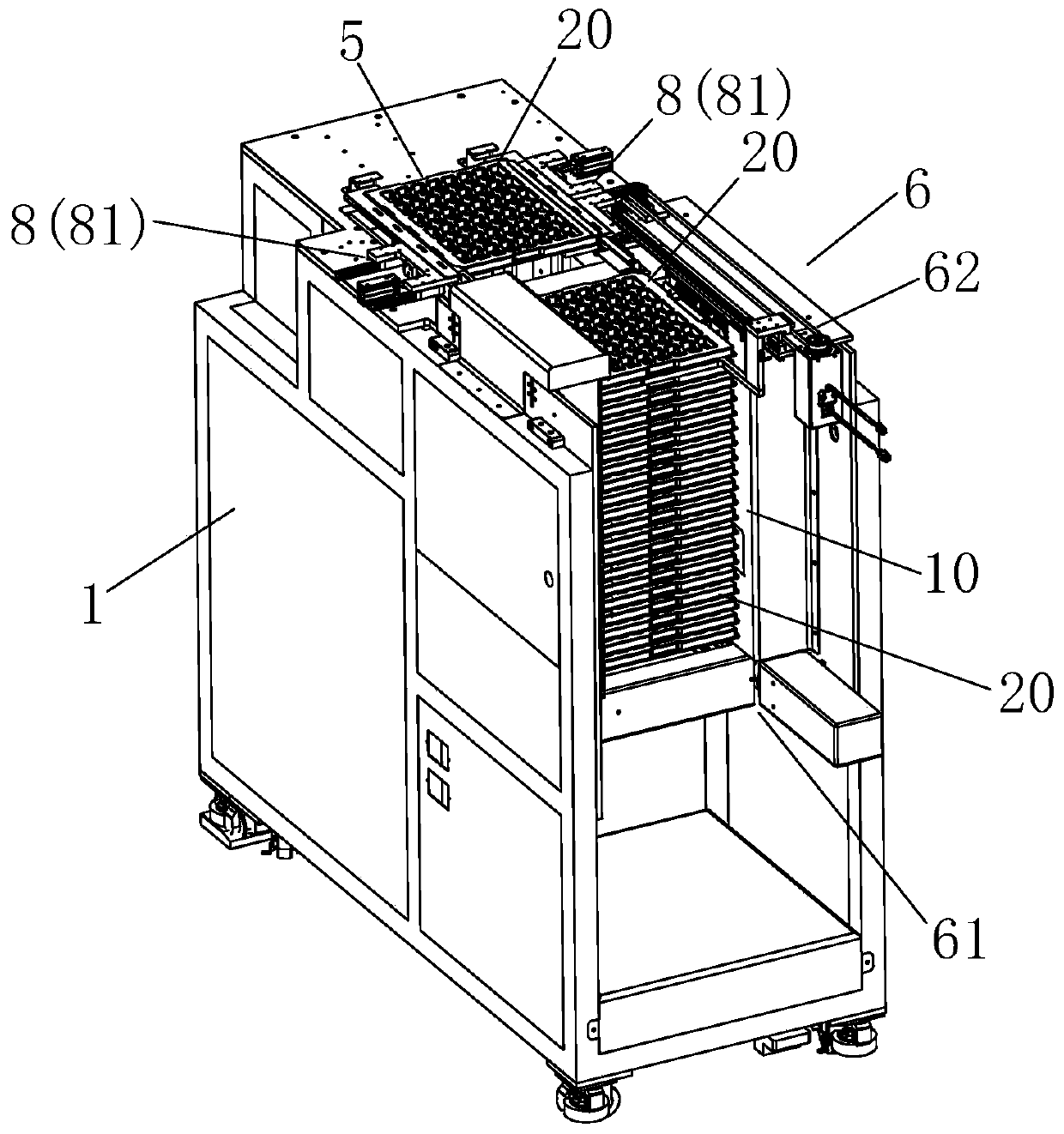

[0031] Please refer to figure 1 , the embodiment of the present invention provides an automatic plate-setting device, including a machine 1, a product feeding manipulator 2, a product plate-setting manipulator 3, a product temporary placing device 4 arranged on the machine 1, a product placed on the machine A product placement area 5 on the platform 1 and located on the side of the product temporary storage device 4, an empty tray feeding and pushing device 6 arranged on the machine platform 1 and located on the side of the product placement area 5, and a product placement area A feeding device 7 below the zone 5. The product 30 is loaded onto the product temporary placement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com