A method and system for subgrade compaction quality detection based on modal parameter identification

A technology for modal parameter identification and compaction quality, applied in roads, roads, road repairs, etc., can solve problems such as few sampling points, overvoltage or undervoltage, not strict intelligent compaction technology, etc., to improve quality and efficiency , to avoid the effect of overvoltage or undervoltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

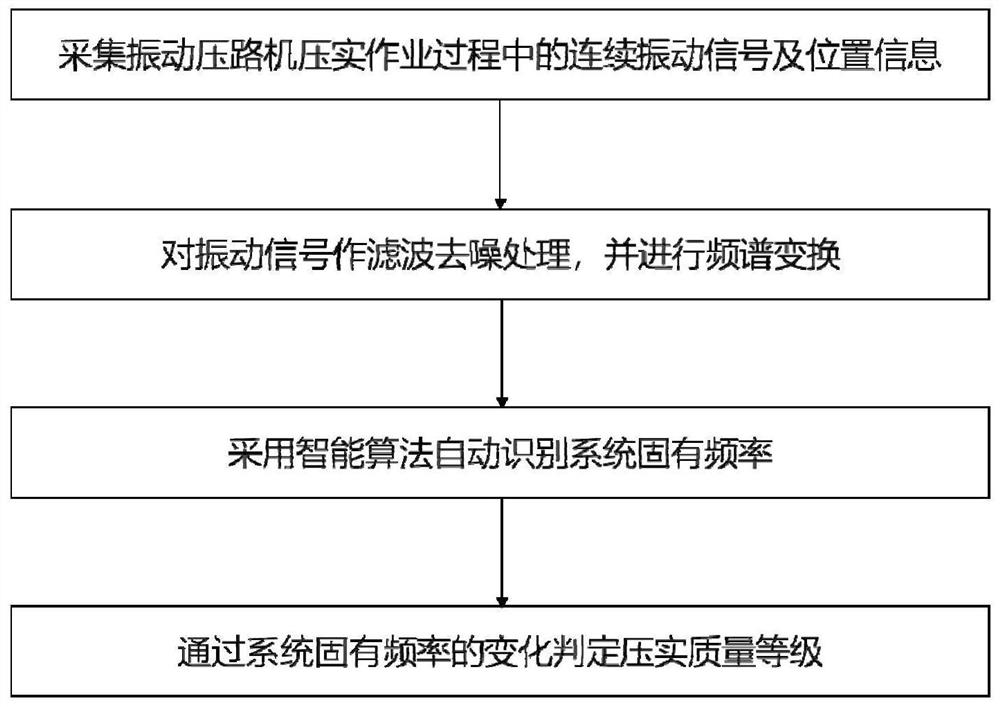

[0048] The present disclosure provides a roadbed compaction quality detection method based on modal parameter identification, including:

[0049] Step 1: Collect the position information and vibration signal during the compaction operation of the road roller, and filter the vibration signal to filter the interference signal;

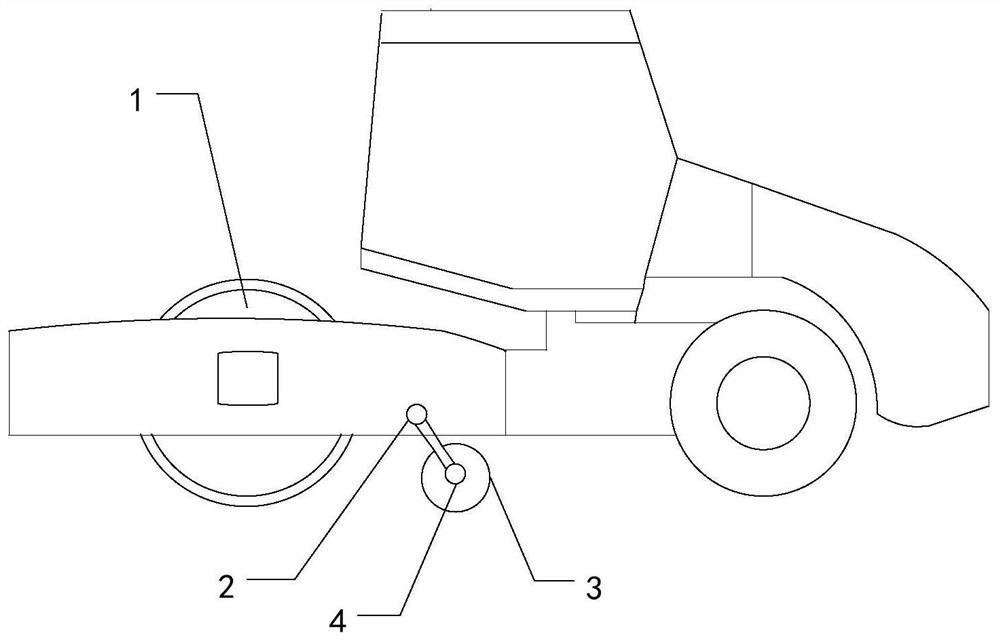

[0050] In said step 1, the position information and the vibration signal at the steel wheel during the operation of the road roller are collected through the GPS positioning device and the vibration signal sensor installed on the road roller; wherein, the location information is consistent with the collection frequency of the vibration signal, so that the position One-to-one correspondence between data and vibration signals;

[0051] The vibration response signal includes system excitation components and system intrinsic attribute components, so it is necessary to filter the vibration response signal, including filtering the simple harmonic excitation fr...

Embodiment 2

[0090] The present disclosure provides a subgrade compaction quality detection system based on modal parameter identification, including:

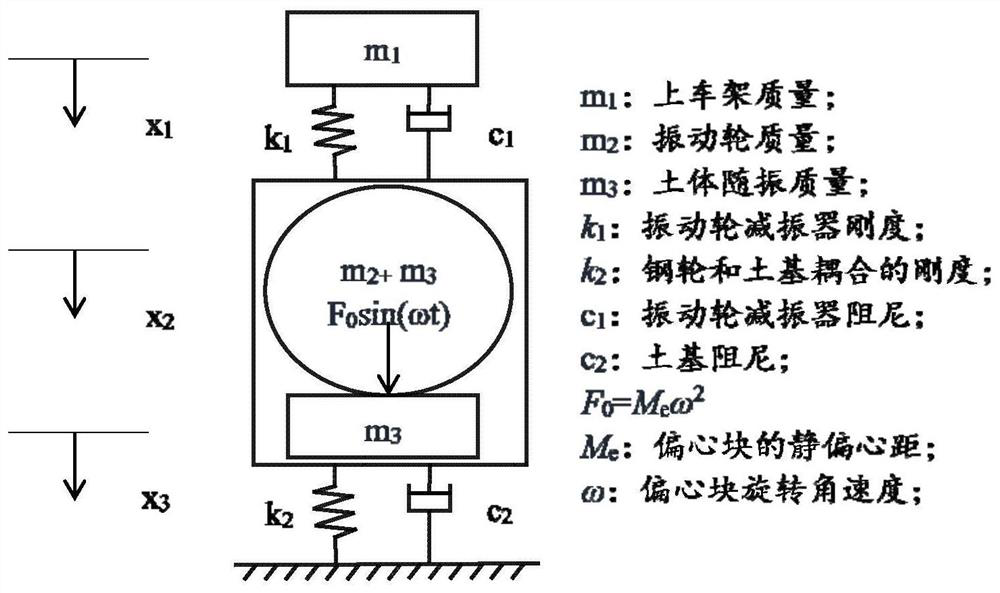

[0091] A signal acquisition module, which is used to obtain position information and vibration signals during the compaction operation of the road roller, perform filtering processing on the vibration signals, perform frequency domain analysis on the filtered vibration signals, and obtain frequency domain signals;

[0092] A signal identification module, which is used to identify the system parameters of the roller-soil vibration system in the frequency domain signal by using the modal parameter identification method to obtain the natural frequency of the system;

[0093] The compaction quality detection module is used to determine the change in the stiffness of the roller-soil vibration system through the change in the natural frequency of the roller-soil vibration system, and determine the change in the compaction quality of the compacted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com