Novel flexible arm TBM propelling hydraulic system and control method

A hydraulic system and flexible arm technology, applied in the new flexible arm TBM propulsion hydraulic system and control field, can solve the problems of insufficient control accuracy and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

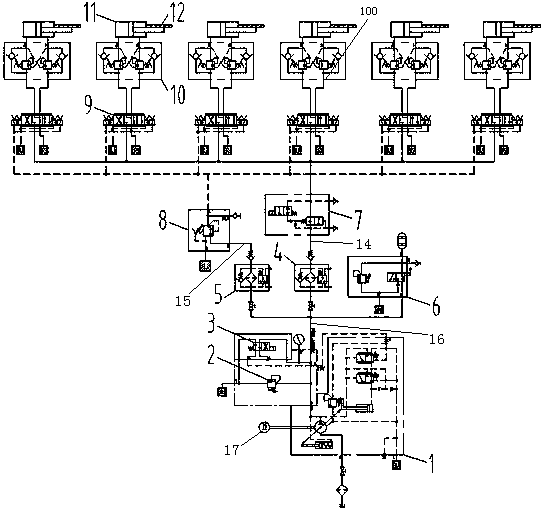

[0030] Embodiment 3, a control method of a novel flexible arm TBM propulsion hydraulic system, is characterized in that: the steps are as follows:

[0031] S1: When starting to work, under the action of the motor 17, the controller controls to open the servo valve 9, and part of the hydraulic oil in the constant pressure pump source 1 enters the servo valve 9 through the external control oil circuit 15;

[0032] S2: Then the hydraulic oil in the constant pressure pump source 1 enters the flexible arm cylinder 11 through the main oil circuit 14 and the servo valve 9, and drives the flexible arm cylinder 11 to perform telescopic movements;

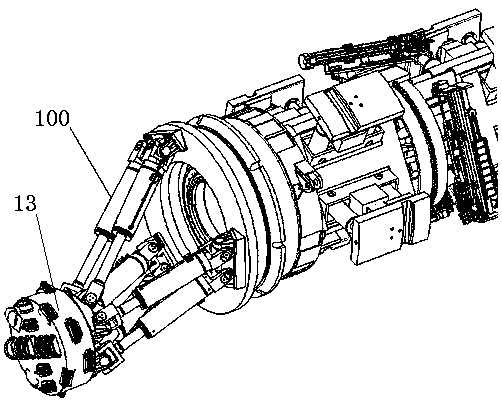

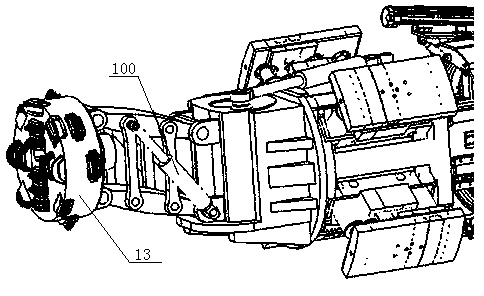

[0033]S3: N flexible arm cylinders 11 of the propulsion cylinder mechanism arranged in parallel act together to adjust the position and angle of the cutter head 13; the displacement sensor 12 transmits the telescopic displacement signal of the flexible arm cylinder 11 to the controller, and the controller controls The servo valve 9 adjusts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com