Guide carriage with piezoresistive layer for load measurement

A piezoresistor and sliding seat technology, which is applied to the measurement of properties and force of piezoresistive materials, measuring devices, force/torque/work measuring instruments, etc., can solve the problems of breakdown, unsuitable for measuring static stress, and high impedance. , to achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

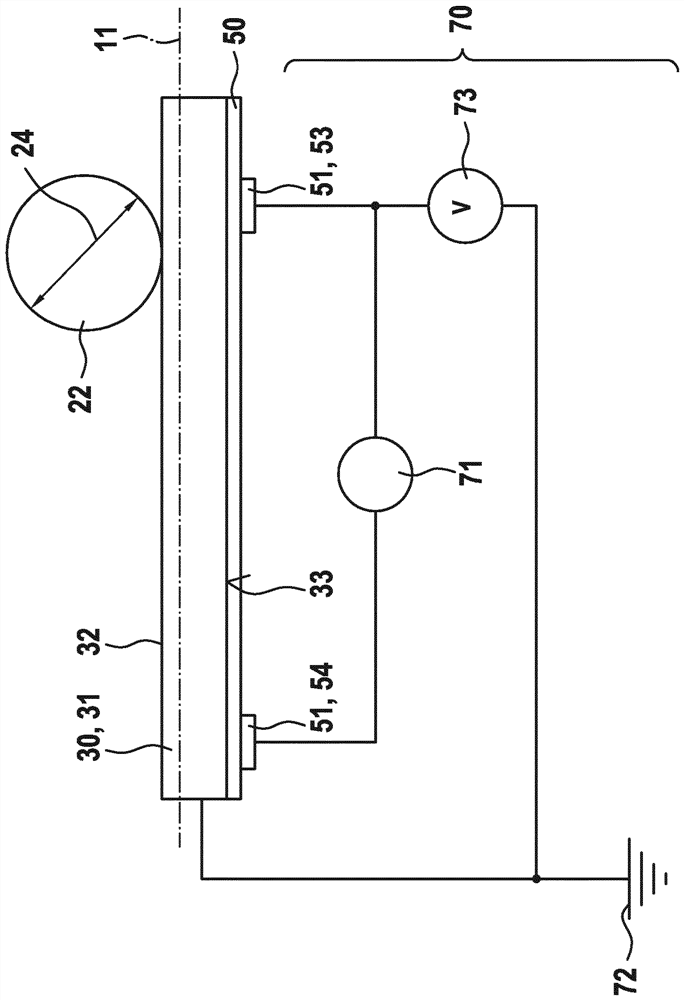

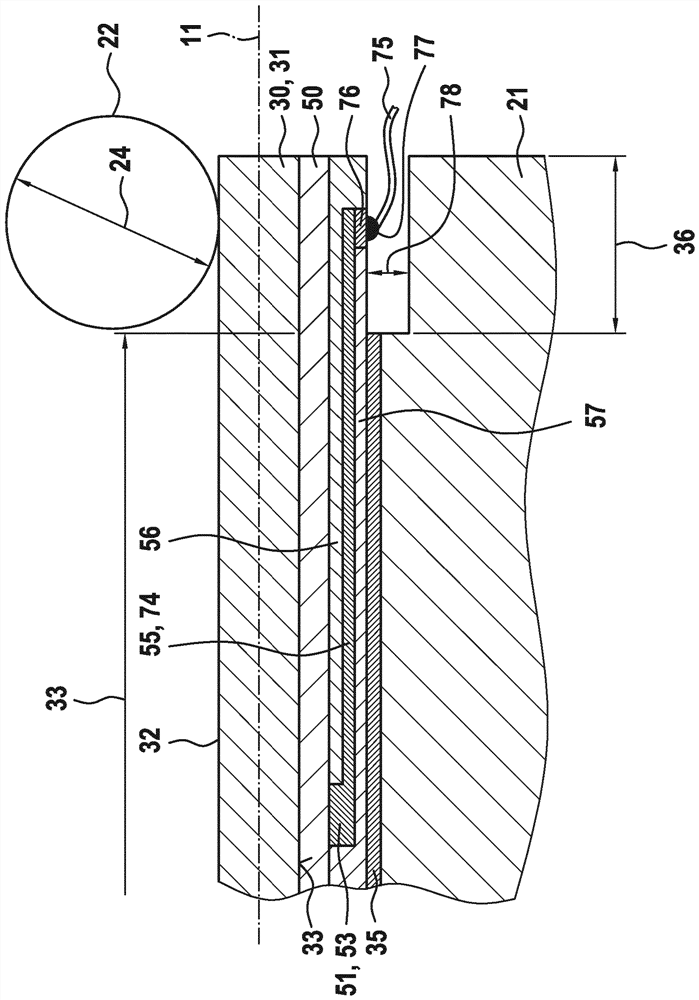

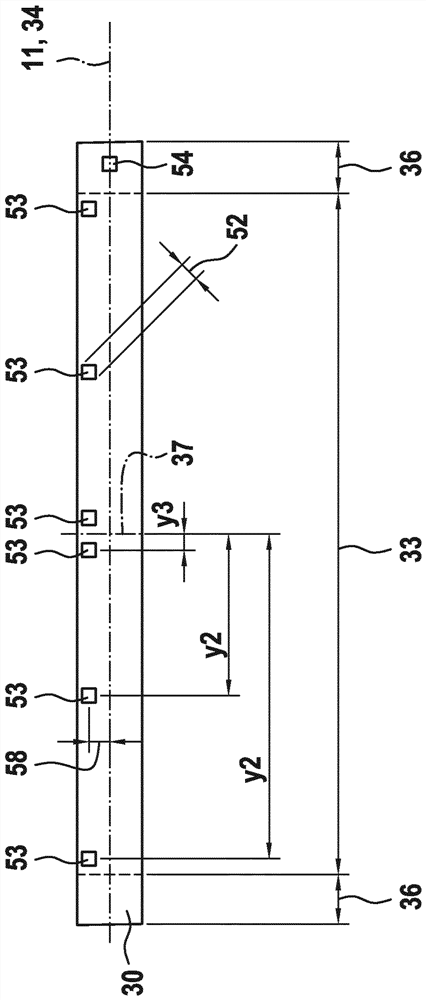

[0030] figure 1A cross-section of a linear rolling bearing 10 with a guide carriage 20 according to the invention is shown. In this case, the guide carriage 20 has four continuously encircling rows of rolling bodies 22 which are designed in the shape of rollers. A row of rolling elements 22 is provided on each raceway insert 30 . The linear rolling bearing 10 is constructed largely according to EP 2 110 571 B1, wherein in particular the raceway insert 30 is bonded to the main body 21 . The invention can also be used for guide carriages with ball-shaped rolling elements and for guide carriages without rolling element surrounds.

[0031] The number of rows of rolling elements can largely be chosen arbitrarily. For example, the invention can also be applied to linear rolling bearings constructed according to EP 2 949 954 B1. Here, ball-shaped rolling bodies are provided, wherein two rows of rolling bodies are assigned to each raceway insert. The raceway insert rests against ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com