Guide carriage having a piezoresistive layer for load measurement

A piezoresistor and sliding seat technology, which is applied in the measurement of the property force of the piezoelectric resistive material, the measuring device, the force/torque/power measuring instrument, etc., can solve the problem of breakdown, high impedance, unsuitable for measuring static stress, etc. Problems, to achieve the effect of favorable cost and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

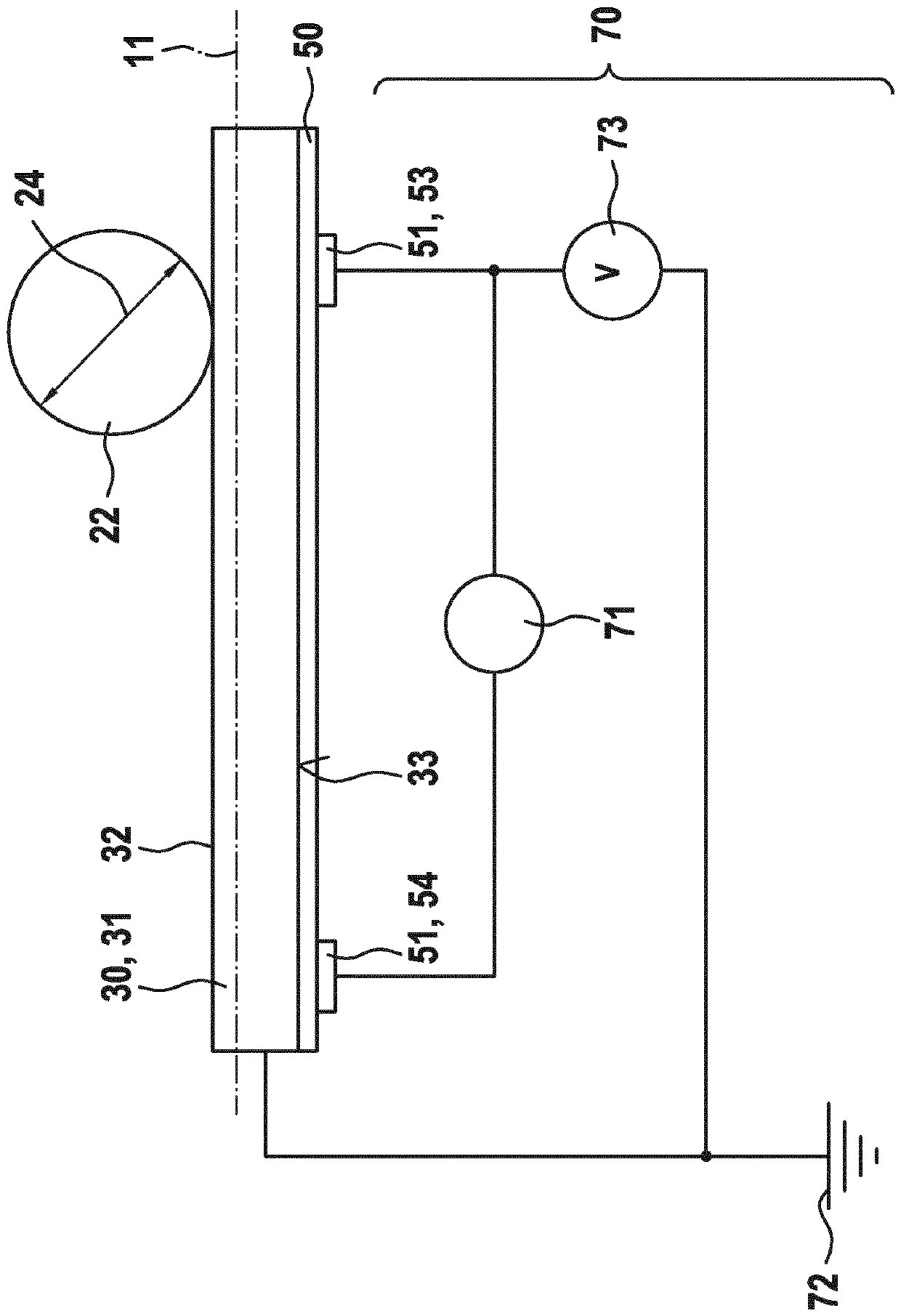

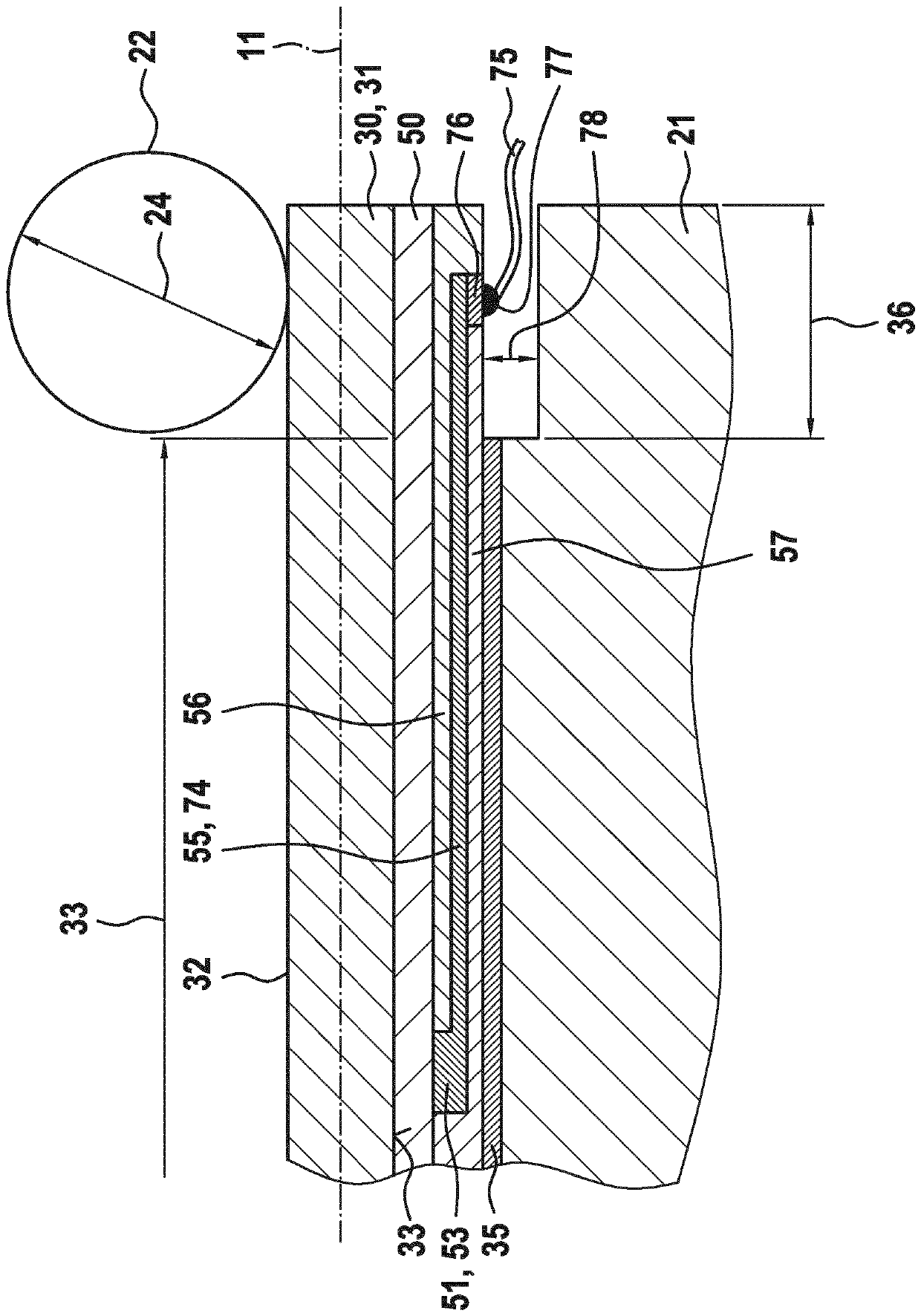

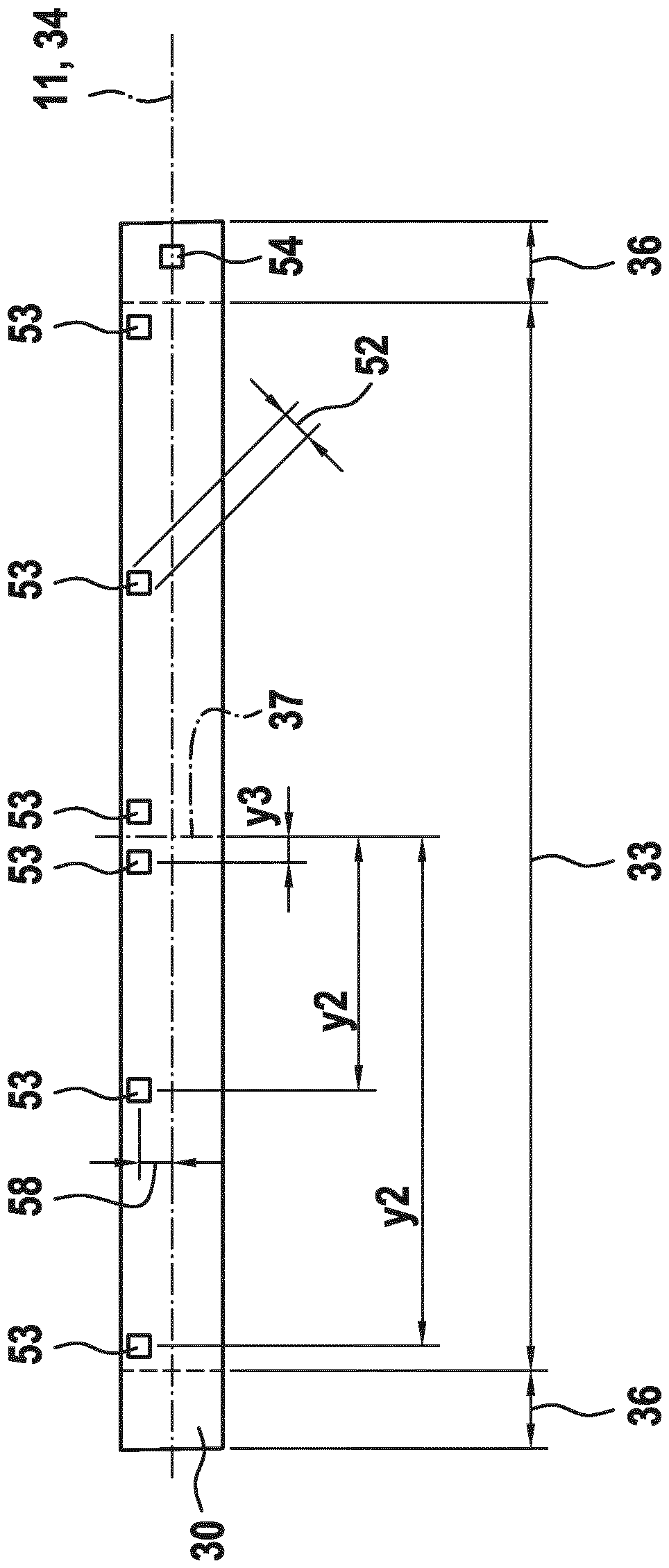

[0030] figure 1A cross-section of a linear rolling bearing 10 with a guide carriage 20 according to the invention is shown. In this case, the guide carriage 20 has four continuous rows of rolling elements 22 , which are designed in the form of rollers. A row of rolling elements 22 is arranged on each raceway insert 30 . The linear rolling bearing 10 is constructed largely according to EP 2 110 571 B1, wherein in particular the raceway insert 30 is glued to the main body 21 . The invention can also be used for guide carriages with ball-shaped rolling elements and for guide carriages without rolling element encirclements.

[0031] The number of rows of rolling bodies can be chosen arbitrarily to a large extent. For example, the invention can also be applied to linear rolling bearings constructed according to EP 2 949 954 B1. Here, ball-shaped rolling elements are provided, wherein two rows of rolling elements are assigned to each raceway insert. The raceway insert rests fri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com