Cultivation and planting device for urban ecological landscape plants

An ecological landscape and planting device technology, which is applied in the field of urban ecological landscape plant cultivation and planting devices, can solve problems such as defects in plant cultivation methods, and achieve the effects of eliminating manual watering, receiving uniform light, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

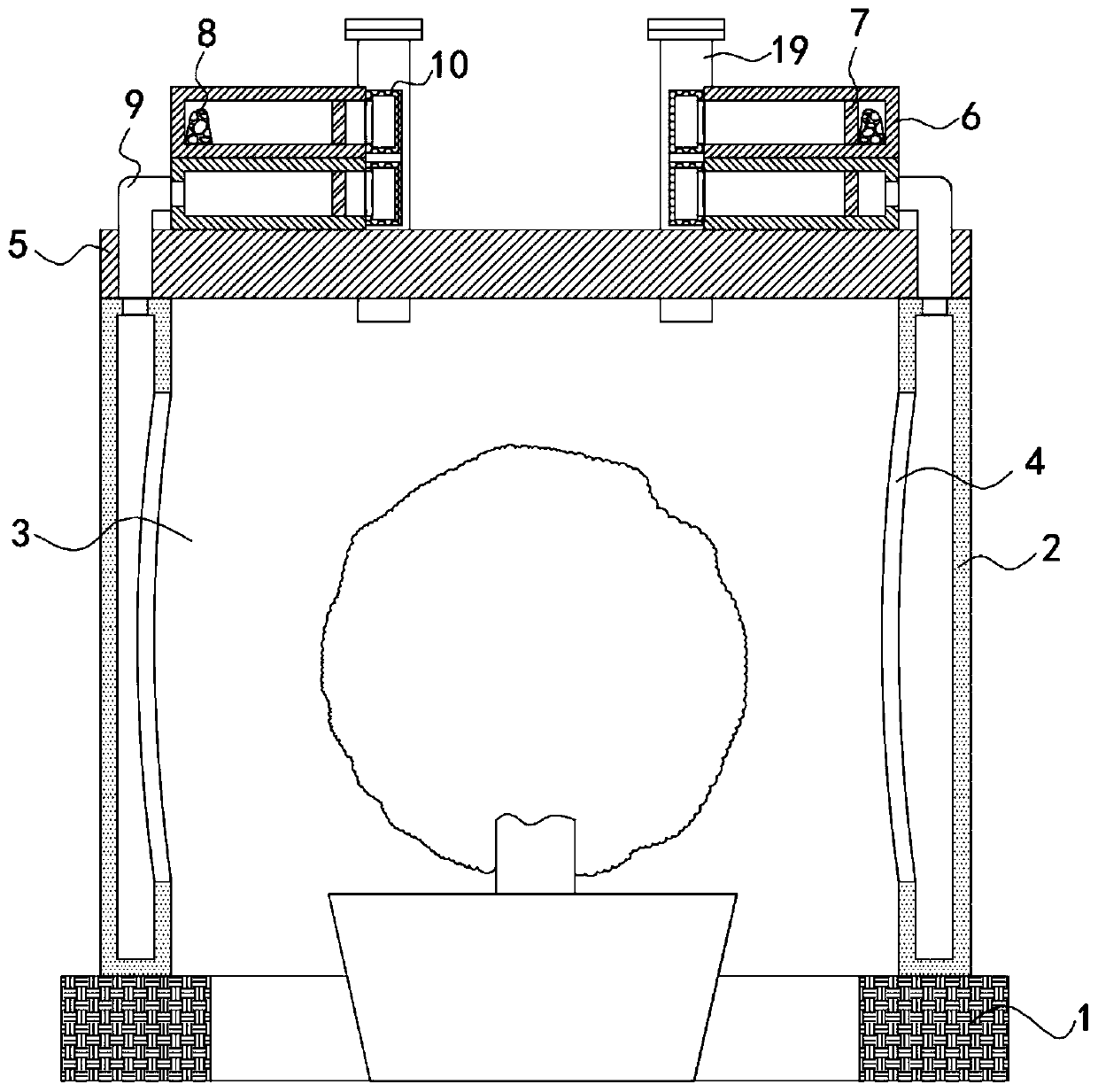

[0020] Such as figure 1 As shown, a cultivation and planting device for urban ecological landscape plants includes a fixed ring 1. When the device is covered on the plant, the setting of the fixed ring 1 can ensure the fixity of the overall device and make the fixing of the device more stable. The upper end of the fixed ring 1 There are at least four vertically arranged hollow glass plates 2 fixedly connected, and a culture chamber 3 is formed between a plurality of glass plates 2, and a light-changing film 4 is inserted through the side wall of the glass plate 2 close to the culture chamber 3. Specifically, The material of the light-changing film 4 can be flexible glass, and the upper ends of multiple glass plates 2 are fixedly connected with the same cover plate 5 .

[0021] In this embodiment, the upper end of the cover plate 5 is provided with an adjustment mechanism corresponding to the position of the glass plate 2. The adjustment mechanism includes two horizontal adjust...

Embodiment 2

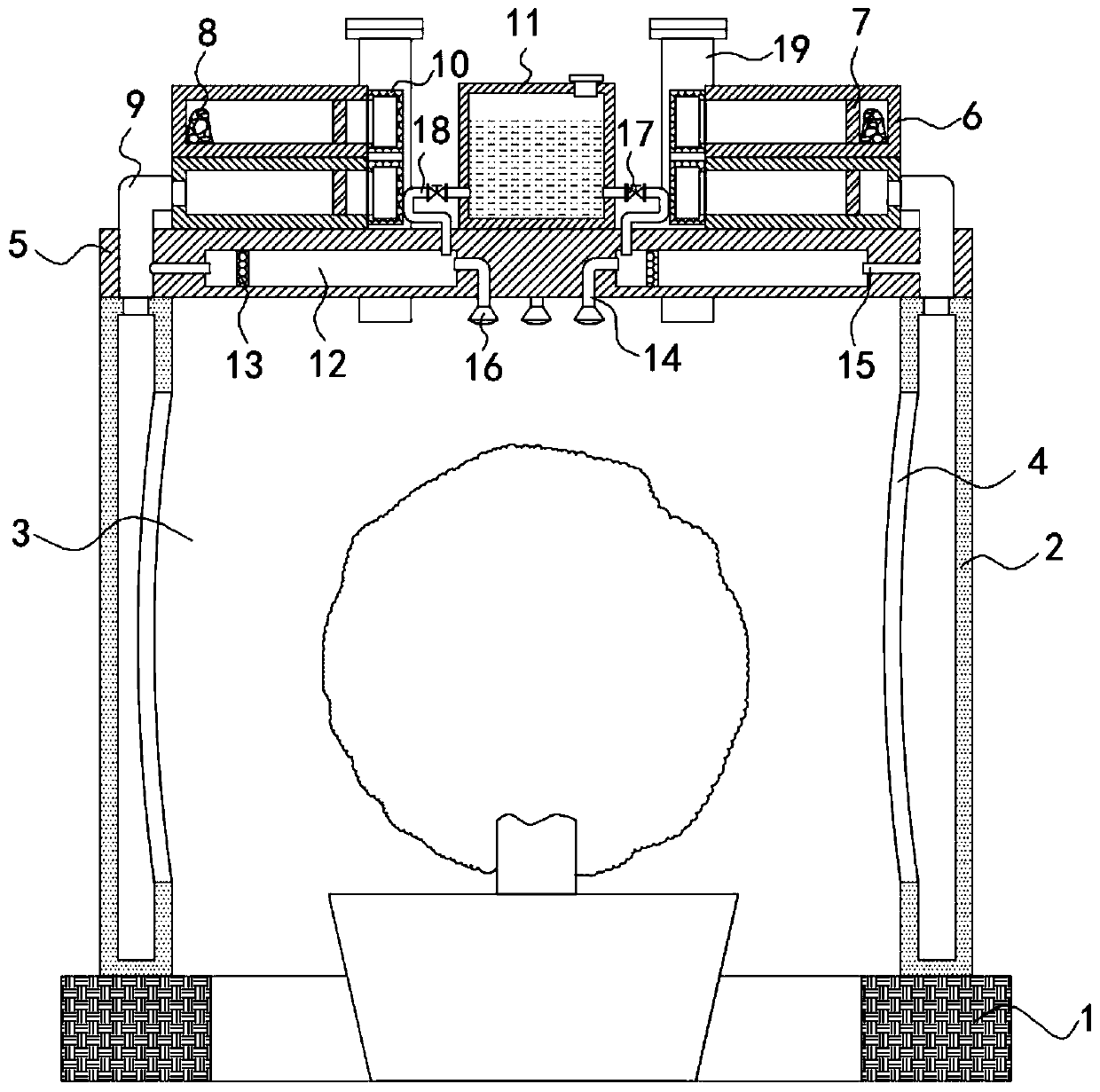

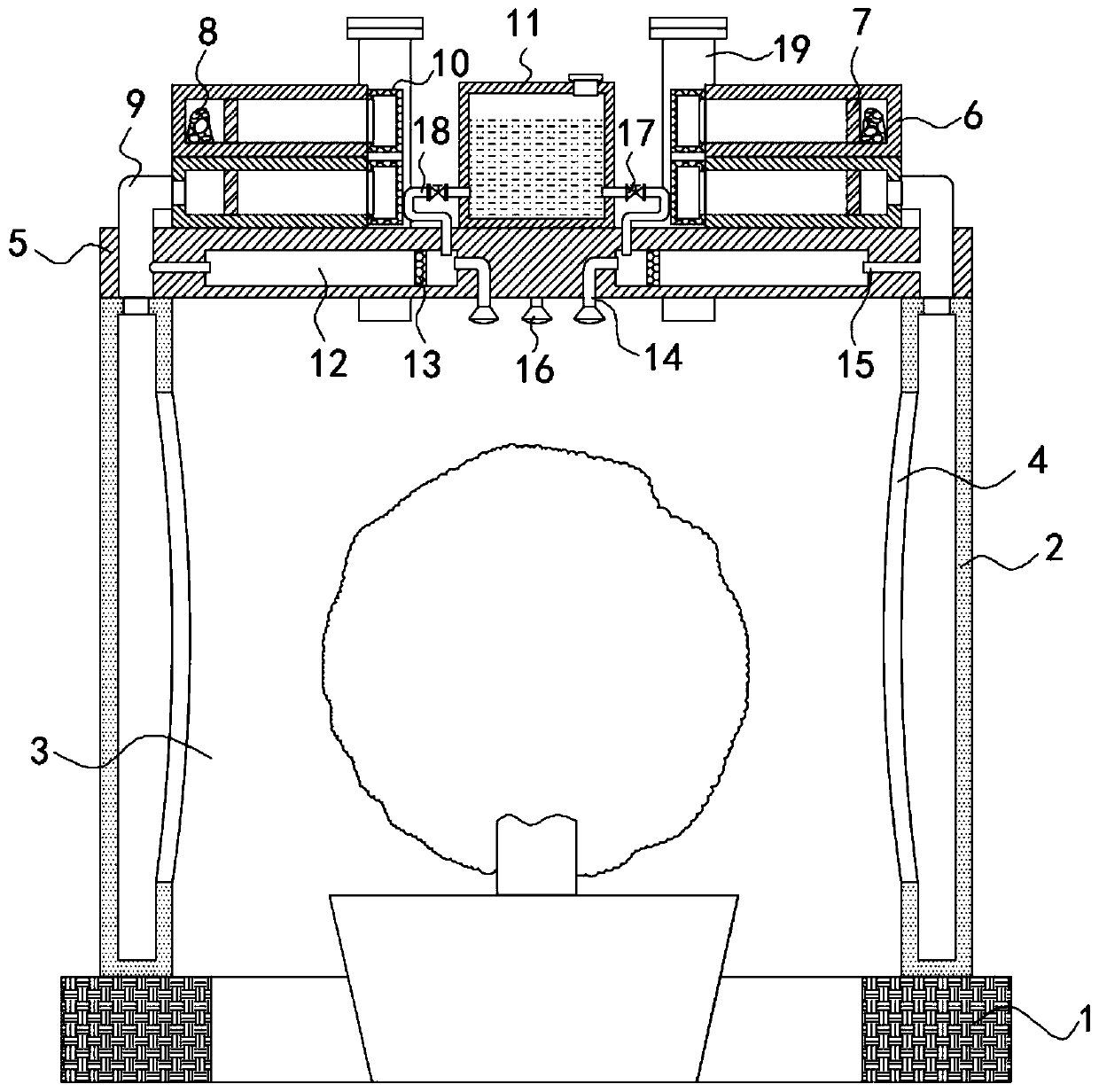

[0026] Such as Figure 2-5 As shown, the difference between this embodiment and Embodiment 1 is that an irrigation mechanism is provided at the upper end of the cover plate 5, and the irrigation mechanism includes a water storage tank 11 fixedly connected to the upper end of the cover plate 5, and a push flow cavity is provided in the cover plate 5. 12. The piston block 13 is sealed and slidably connected in the push flow chamber 12. The water storage tank 11 communicates with the inside of the push flow chamber 12 through the water inlet pipe 18. One end of the push flow chamber 12 communicates with the connecting pipe 9 through the branch pipe 15. The cultivation chamber 3 There is a nozzle 16 inside, and the nozzle 16 communicates with the inside of the push flow chamber 12 through the water outlet pipe 14. It is worth mentioning that a check valve 17 is connected in series in the middle of the water inlet pipe 18, and the check valve 17 only allows water in the water storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com