Paste mixing auxiliary material adding system

A paste auxiliary material and server technology, applied in transportation and packaging, chemical instruments and methods, dissolution, etc., can solve problems such as difficulty in finding mistakes and identifying responsible personnel, scrapping and unusable lead paste, and reducing the quality and performance of lead paste. The effect of adding wrong ingredients, avoiding mistakes, and correct order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

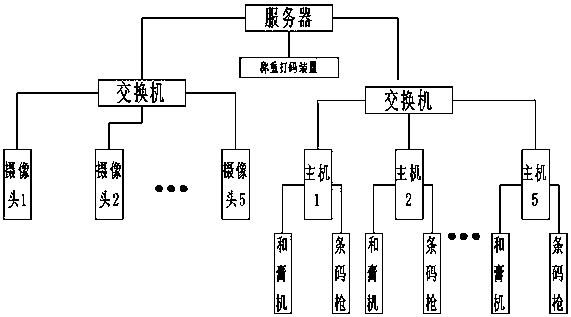

[0018] Such as figure 1 The paste blending auxiliary material adding system shown includes a switch, a camera, a barcode gun, a server, a PLC host and a paste blending machine controlled by the PLC host. There are 5 blending paste machines, and each blending paste machine corresponds to one PLC host, a camera and a barcode gun, PLC host, server, switch, and camera form a local area network, the barcode gun is connected to the server data through the LAN, and the camera monitors the corresponding area of the paste machine; it also includes a weighing and coding device. The re-coding device is connected with the server.

Embodiment 2

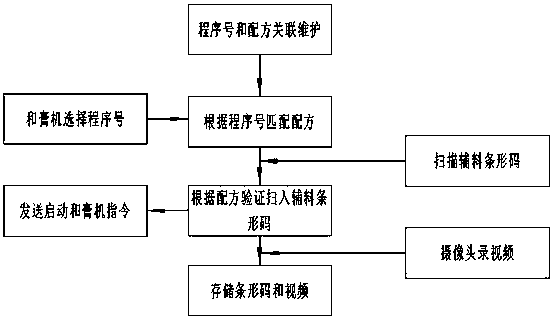

[0020] Such as figure 2 A method for adding auxiliary materials for blending paste includes the following processes:

[0021] 1. Pre-process; code each auxiliary material separately and independently number each paste machine;

[0022] 2. Technicians enter the blending paste formula through the host computer, and store it in the server and the PLC of the blending paste machine; each blending paste formula has an independent program number, and the program number is associated with the corresponding paste machine number;

[0023] 3. When blending paste, when a paste blending machine starts to select the program number, the server will call out the auxiliary materials required for the program number and the number of the paste blending machine;

[0024] 4. In the formula room, weigh the ingredients according to the formula. The weighing and coding device weighs each material required according to the formula of the paste and generates a barcode. The barcode includes the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com