A top rotating composite panel storage device

A storage device and composite board technology, which is applied to conveyor control devices, packaging, transportation and packaging, etc., can solve problems such as low storage efficiency, and achieve the effect of improving work efficiency and efficient and convenient storage process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

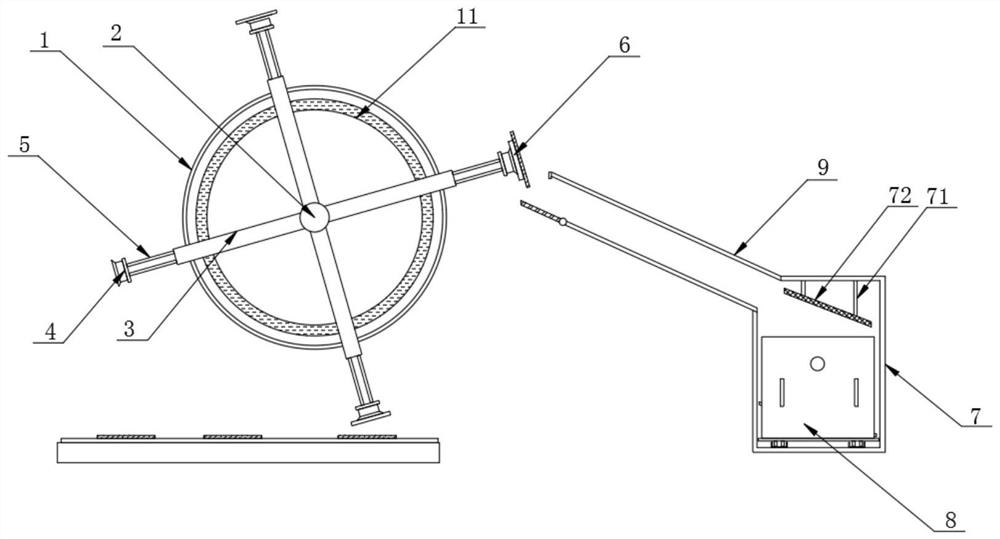

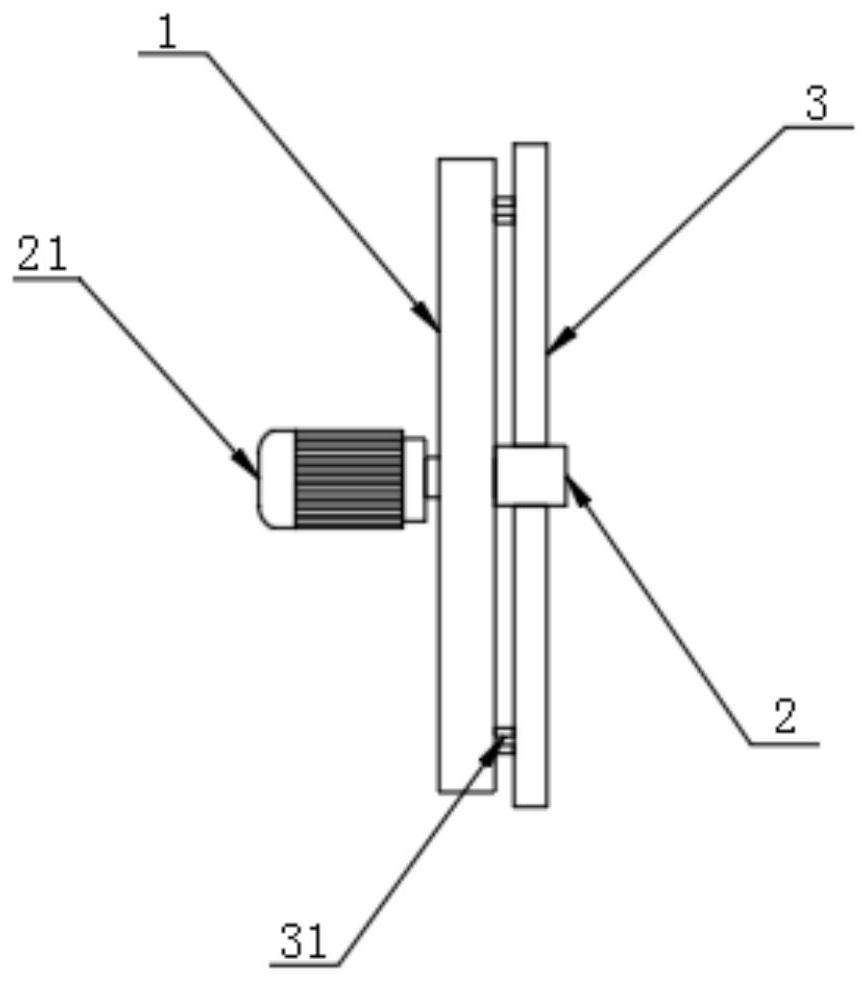

[0033] Refer Figure 1-4 A top rotary composite plate storage device, including a motherboard 1, and a rotating seat 2 is provided on the front side surface of the moving seat 2, and the rotating shaft 3 is disposed. The rotation shaft 3 The outer side is provided with a lifting plate 4, and the rotating shaft 3 is provided with a drive mechanism 5 between the lifting plate 4, and the outer side of the lifting plate 4 is uniformly provided with a vacuum suction cup 6, and the main board 1 is provided with a storage box 7. A storage tank 8 is provided inside the accommodating box 7, and the receiving tank 9 is connected at one end of the tank 7.

[0034] The main board 1 is provided with a slide groove 11, and the rotating shaft 3 is uniformly provided with a mandrel wheel 31, and the universal wheel 31 is slidably connected to the slide groove 11, and the main board 1 is a production line conveyor belt, conveyor belt. The surface is transmitted in accordance with the predetermined ...

Embodiment 2

[0041] The pressure plate 71 is provided inside the storage box 7, and the pressure plate 71 is uniformly provided with a hydraulic lifting lever 72 between the top of the inner wall of the storage case 7, and the inner wall of the storage box 7 is provided with a traveling groove, the traveling groove for storage. Car 8 moves.

[0042] The top surface of the storage vehicle 8 is provided with weighing instrument 81, and the top of the weighing device 81 is fixed, and the carrier plate 82 is inclined, and the carrier plate 82 is provided with a limited bit plate 83. The carrier plate 82 is fixed to a push plate 84, and the push plate 84 is provided with a pull ring 85, and a alarm 86 is provided at the top of the pull ring 85.

[0043] The specific embodiment is that the storage vehicle 8 carries the composite plate in the storage case 7, and the composite panel is slid from the receiving groove 9 to the carrier plate 82 of the surface of the storage vehicle 8, and the weight of t...

Embodiment 3

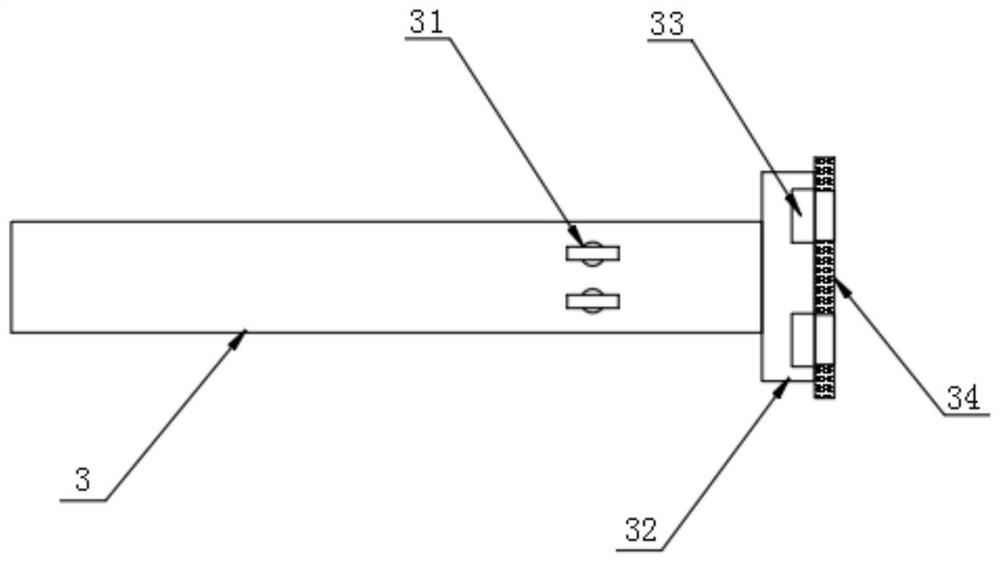

[0045] The absorbent plate 41 is provided at the bottom of the lifting plate 4, and the adsorbent plate 41 is fixed to the lifting plate 4, and a connecting rod 42 is provided with a plurality of vacuum generators 43, the adsorbent plate. The front side and rear side surfaces are fixedly provided with a side seat 44, and the side seat 44 is hollow disposed and an electric push rod is provided inside, and the outer side seat 44 is provided with a sliding guide rail 45, the sliding rail 45 surface There is a slider 46, the slider 46 is slidably connected to the sliding guide rail 45 and is connected to the electric push rod, and the slider 46 is fixedly provided with a top plate 47.

[0046] The storage tank 9 includes a first transfer plate 91, a second transport plate 92, a hinge seat 93, an elastic pad 94, and a casing 95, and the first end of the first transport plate 91 and the second transport plate 92 and the receiving box 7 A fixed connection, the second transfer plate 92 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com