A kind of double-layer co-extruded insulating LED ultraviolet cross-linked color low-smoke halogen-free flame-retardant cable material and its preparation method

A flame-retardant cable material, double-layer co-extrusion technology, applied in the direction of insulated cables, cable/conductor manufacturing, insulators, etc., can solve problems such as aging, high cable prices, fire, etc., achieve stable electrical performance, realize rapid industrial production, The effect of high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solutions in the embodiments of the present invention will be apparent from the embodiments of the present invention, and embodiments, are intended, as described in the embodiments of the invention, not all of the embodiments of the invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0055] The technical solutions of the present invention are further detailed below in connection with specific embodiments, but the present invention is not limited to these examples.

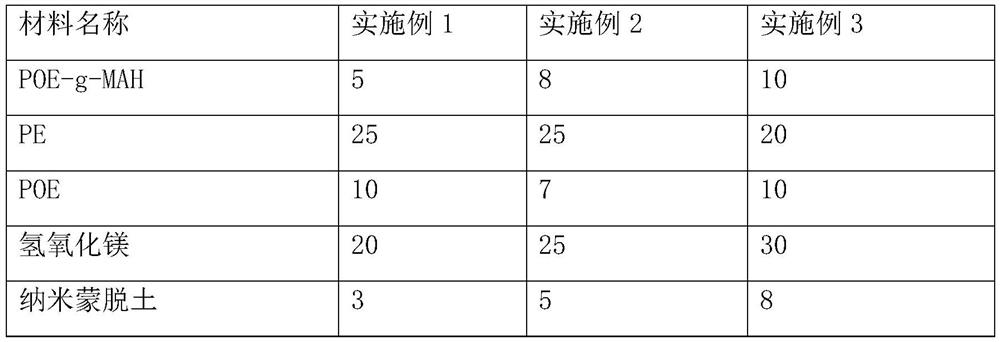

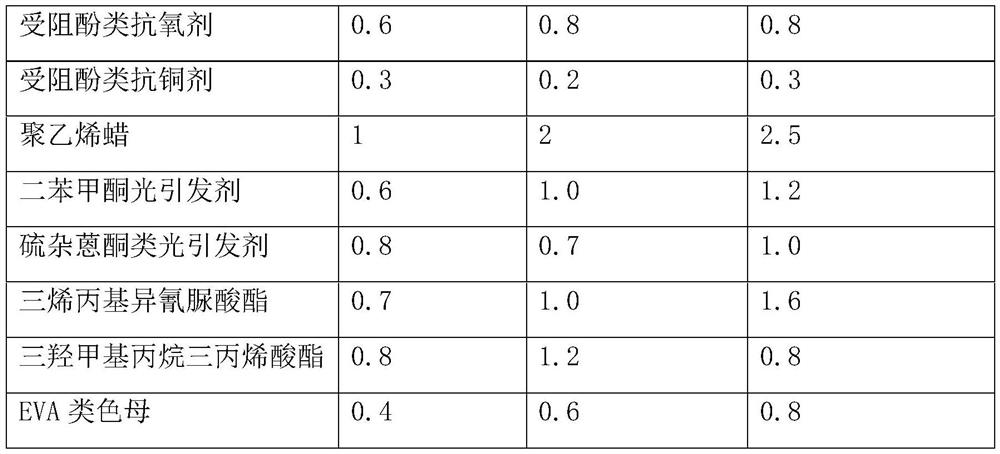

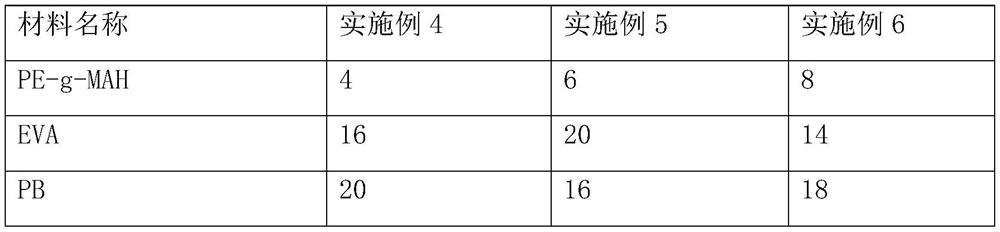

[0056] (1) Double co-extrusion insulation LED UV optical crosslinked color low smoke halogen-free flame retardant cable material inner insulation material Each component weight parts should be seen in Table 1:

[0057] Table 1 Composition of the raw material of the inner layer insulating material

[0058]

[0059]

[0060] The preparation method of the inner layer insulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com