Surface modification method of antimonous oxide special for flame-retardant masterbatch

A technology of antimony trioxide and flame retardant masterbatch, which is applied in the field of preparation of active antimony trioxide, which can solve the problems of poor flame retardant synergistic effect of antimony trioxide, poor molecular affinity of polymers, and difficulty in uniform dispersion. Achieve the effects of improving poor thermal stability, shortening modification time, and enhancing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

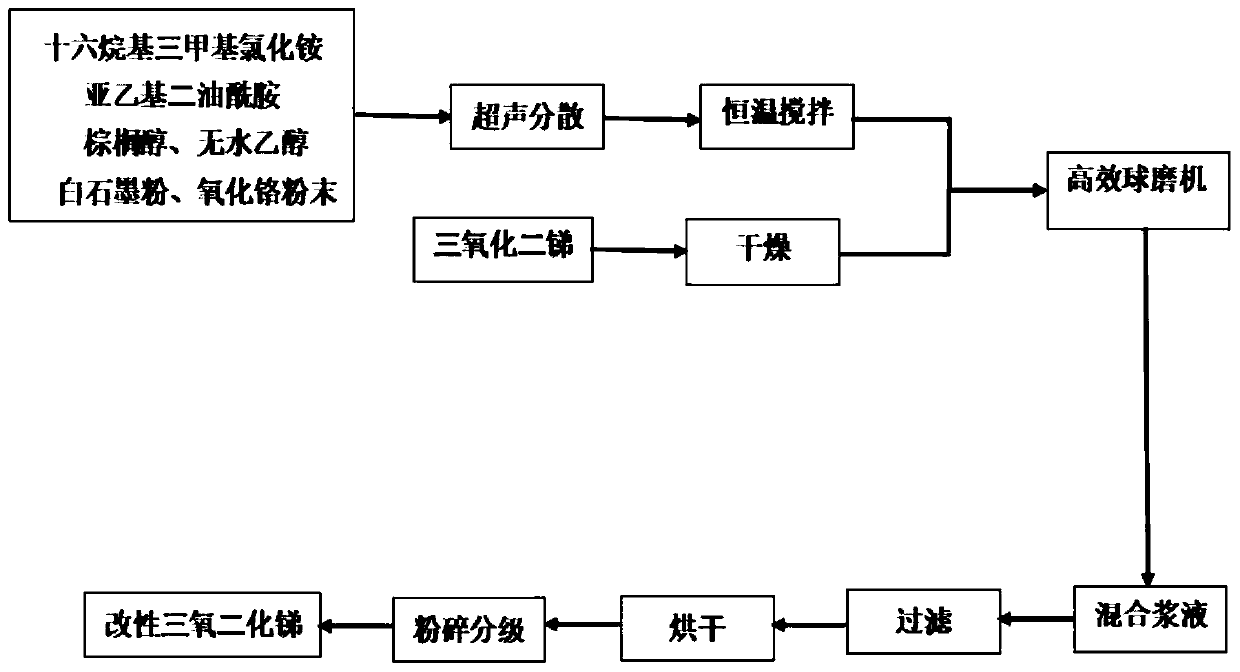

[0028] Such as figure 1 As shown, a surface modification method of antimony trioxide special for flame retardant masterbatch, comprising the following steps:

[0029] S1. Weigh 4 parts of white graphite powder, 3 parts of chromium oxide powder, 50 parts of antimony trioxide, 3 parts of cetyltrimethylammonium chloride, and ethylene dioleamide according to the weight and number ratio of each raw material 6 parts, palm alcohol 1 part, absolute ethanol 95 parts;

[0030] S2. Mix white graphite powder, chromium oxide powder, cetyltrimethylammonium chloride, ethylene dioleamide, palmityl alcohol, and absolute ethanol, and after the ultrasonic dispersion time is 35min at an ultrasonic frequency of 55HZ, After stirring at 40°C for 25 minutes, the mixed material A was obtained;

[0031] S3. First put the antimony trioxide dried at 50°C for 2 hours into a high-efficiency ball mill with a rotation speed of 750rpm / min for 5 minutes, then add the mixed material A and ball mill for 7 hour...

Embodiment 2

[0033] Such as figure 1 As shown, a surface modification method of antimony trioxide special for flame retardant masterbatch, comprising the following steps:

[0034] S1. Weigh 2 parts of white graphite powder, 5 parts of chromium oxide powder, 55 parts of antimony trioxide, 4 parts of hexadecyltrimethylammonium chloride, and ethylene dioleamide according to the weight and number ratio of each raw material. 4 parts, palm alcohol 1.5 parts, absolute ethanol 98 parts;

[0035] S2. Mix white graphite powder, chromium oxide powder, cetyltrimethylammonium chloride, ethylene dioleamide, palmityl alcohol, and absolute ethanol, and after the ultrasonic dispersion time is 30min at an ultrasonic frequency of 60HZ, After stirring at 45°C for 20 minutes, the mixed material A was obtained;

[0036]S3. First put the antimony trioxide dried at 55°C for 2 hours into a high-efficiency ball mill with a rotating speed of 600rpm / min for 8 minutes, then add the mixed material A and ball mill for...

Embodiment 3

[0038] Such as figure 1 As shown, a surface modification method of antimony trioxide special for flame retardant masterbatch, comprising the following steps:

[0039] S1. Weigh 4 parts of white graphite powder, 4 parts of chromium oxide powder, 60 parts of antimony trioxide, 3.5 parts of cetyltrimethylammonium chloride, and ethylene dioleamide according to the weight and number ratio of each raw material. 5 parts, palm alcohol 2 parts, absolute ethanol 90 parts;

[0040] S2. Mix white graphite powder, chromium oxide powder, cetyltrimethylammonium chloride, ethylene dioleamide, palmityl alcohol, and absolute ethanol, and after the ultrasonic dispersion time is 25min at an ultrasonic frequency of 65HZ, After stirring at 50°C for 30 minutes, the mixed material A was obtained;

[0041] S3. Put the antimony trioxide dried at 45°C for 3 hours into a high-efficiency ball mill with a rotation speed of 800rpm / min for 6 minutes, then add the mixed material A and ball mill for 6 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com