Thermal-conducting carbon fiber coating, and preparation method, application and building thereof

A thermally conductive coating and carbon fiber technology, applied in conductive coatings, applications, construction, etc., can solve problems such as low safety performance, high power consumption, small heating range of electric heating oil and small sun, etc., to achieve safe use and low energy consumption Low temperature and large temperature rise range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

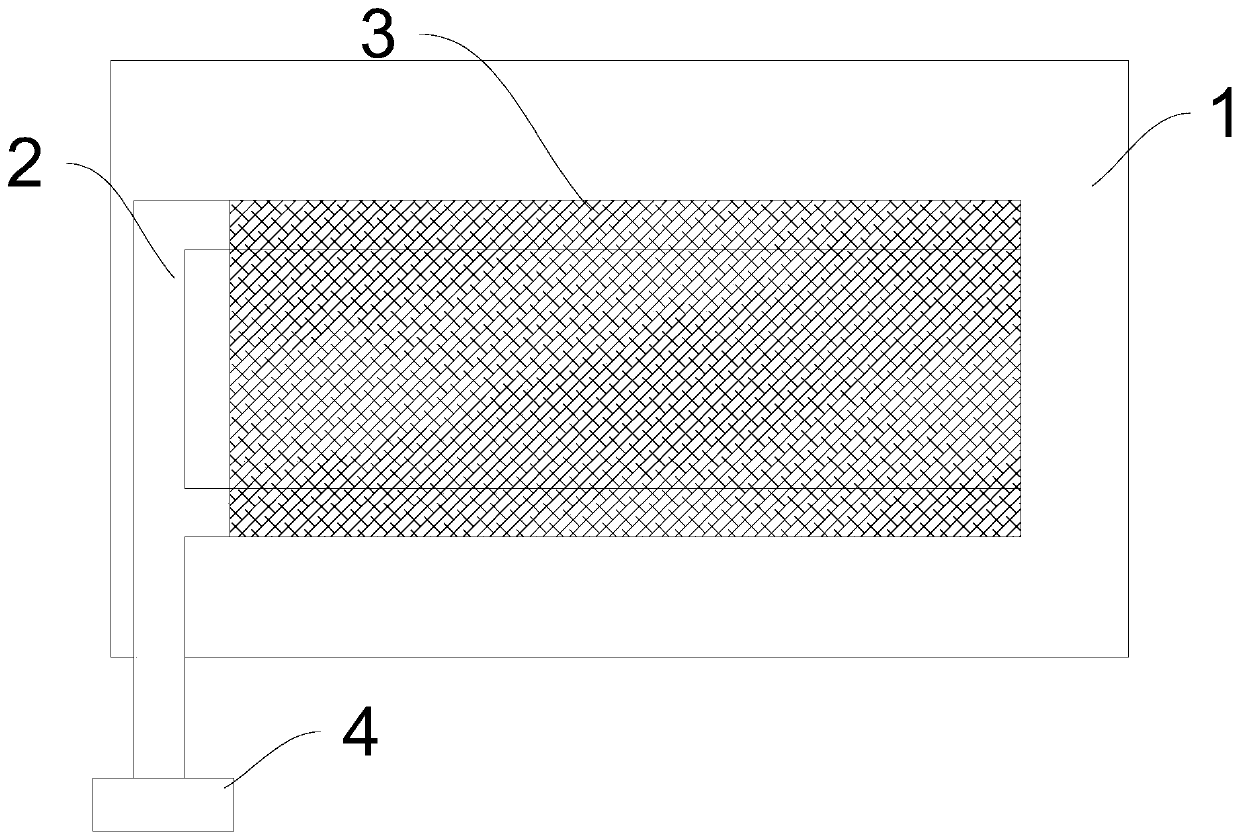

Image

Examples

Embodiment 1

[0042] Mix 0.1kg of carbon fiber, 20kg of pure acrylic emulsion, 0.1kg of film-forming aid, 5kg of conductive carbon powder, 25kg of graphite, 0.5kg of seashell mud and 0.5kg of titanium dioxide to obtain a carbon fiber thermal conductive coating, in which the carbon fiber is 27k, and the length is selected 1.0mm carbon fiber; apply carbon fiber heat-conducting paint to the building, first stick the conductor on the wall of the building, then apply the carbon fiber heat-conducting paint on the wall and cover the conductor, then connect the conductor to the power supply, and start the power supply , the building wall can generate heat.

Embodiment 2

[0044] Mix and stir 10kg of carbon fiber, 60kg of pure acrylic emulsion, 2kg of film-forming aid, 25kg of conductive carbon powder, 40kg of graphite, 8kg of seashell mud and 8kg of titanium dioxide to obtain a carbon fiber thermal conductive coating, in which the carbon fiber is 24k, and the length is 1.2mm. Carbon fiber; apply carbon fiber thermal conductive coating to the building, first stick the conductor on the wall of the building, then apply the carbon fiber thermal conductive coating on the wall and cover the conductor, then connect the conductor to the power supply, start the power supply, and build the wall It will heat up.

Embodiment 3

[0046] Mix 0.8kg of carbon fiber, 40kg of pure acrylic emulsion, 0.1kg of film-forming aid, 10kg of conductive carbon powder, 25kg of graphite, 2kg of seashell mud and 1kg of titanium dioxide to obtain a carbon fiber thermal conductive coating, in which the carbon fiber is 24k, and the length is 0.8 mm of carbon fiber; apply carbon fiber thermal conductive coating to the building, first paste the conductor on the wall of the building, then apply the carbon fiber thermal conductive coating to the wall and cover the conductor, then connect the conductor to the power supply, start the power supply, and build The wall will heat up.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com