A Micropile Reinforcement Method for Controlling the Transverse Uneven Settlement of High-Speed Railway Wide Embankment

A technology of micro-piles and high-speed railways, applied in the directions of roads, sheet pile walls, tracks, etc., can solve the problems of increasing the total cost of embankments, waste, and uneconomical construction of high-speed railways, etc. Economical cost, effect of reducing the number and depth of micropiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

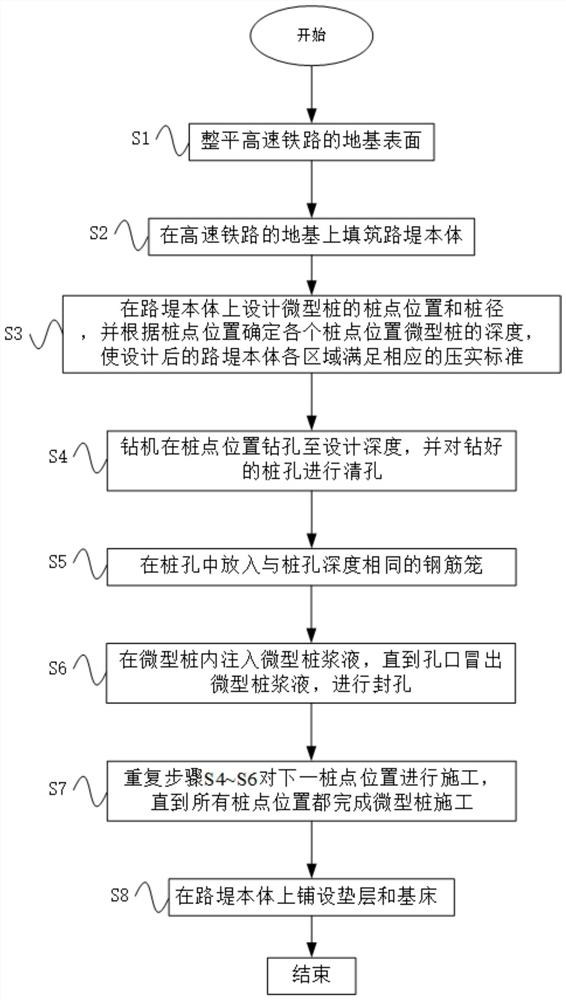

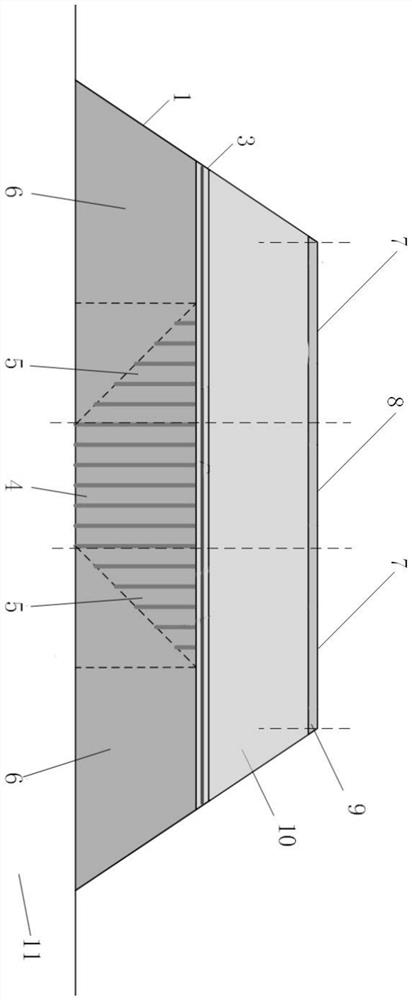

[0042] A micro-pile reinforcement method to control the lateral uneven settlement of high-speed rail wide embankments, such as figure 1 As shown, the reinforcement method includes the following steps:

[0043] S1: Level the surface of the foundation 11 of the high-speed railway.

[0044] S2: Fill the embankment body 1 with chemically modified soil as material on the foundation of the high-speed railway, so that the embankment body 1 after filling meets the compaction standard of the embankment body, and the compaction standard of the embankment body is that the compaction coefficient is not less than 0.90 and 7d is saturated The unconfined compressive strength is not less than 200kPa.

[0045] S3: Design the pile point positions and corresponding pile diameters of the micropile 2 on the embankment body 1, and determine the depth of the micropile 2 at each pile point position according to the pile point positions, so that each area of the designed embankment body 1 meets the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com