A method for assembling a prefabricated steel frame structure to form a house

A steel frame and assembly technology, which is applied in the direction of building structure and construction, can solve the problems of environmental pollution, slow construction speed, poor control of welding quality standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

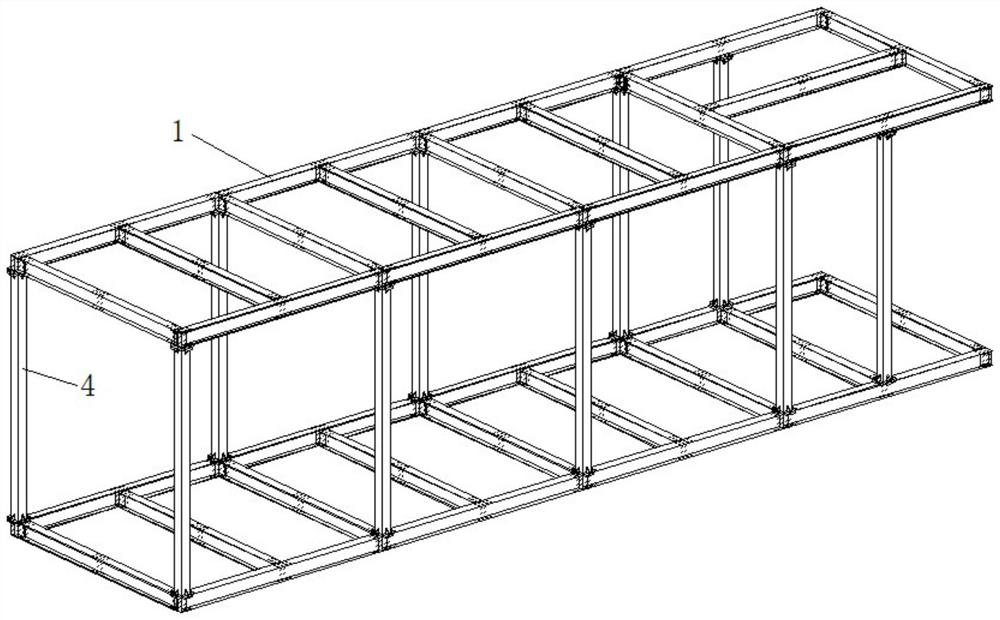

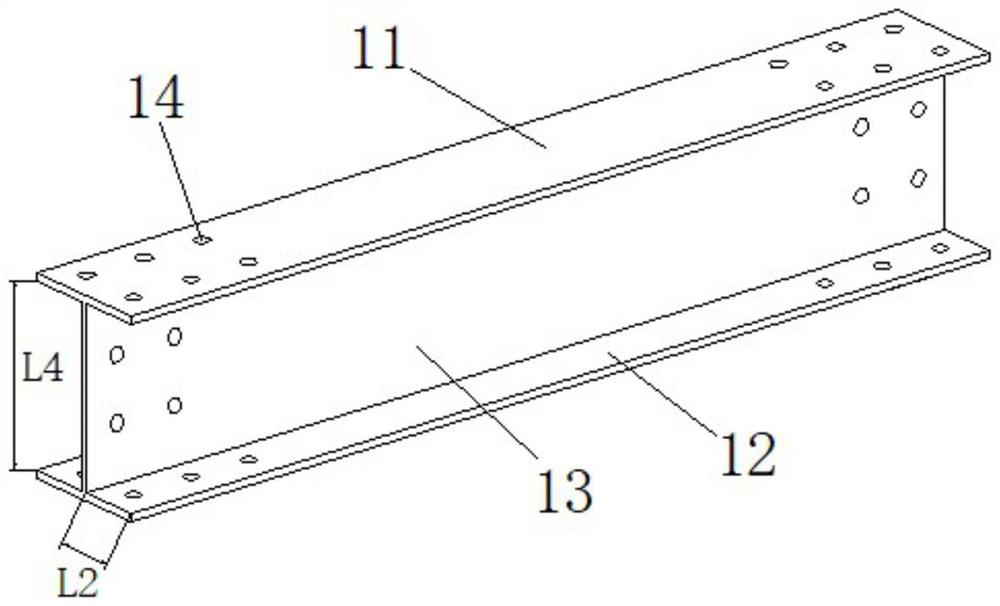

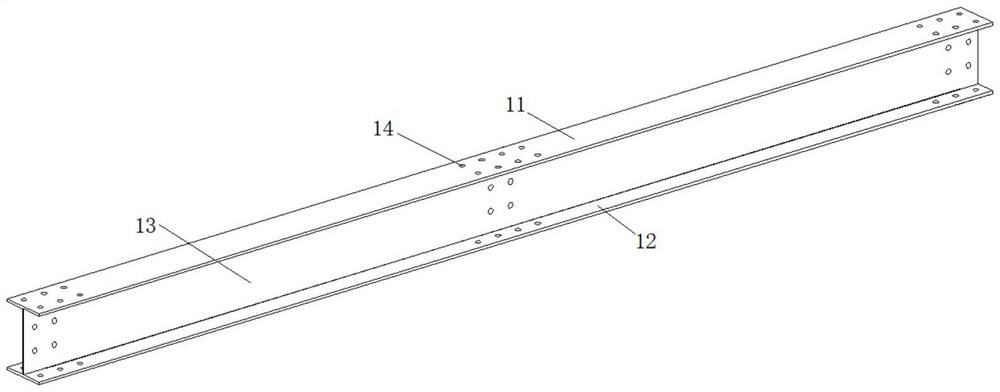

[0040] A method for assembling a prefabricated steel frame structure to form a house according to the present invention, the method adopts a prefabricated steel frame structure system, and the prefabricated steel frame structure system includes H-shaped steel beams 1, connectors 2, bolts 3 and a steel square column 4, the H-shaped steel beam 1 includes an upper flange plate 11, a lower flange plate 12 and a web 13, and a plurality of passages are arranged at both ends of the length direction of the H-shaped steel beam 1 Holes 14; the connector 2 includes a fixedly connected upper connecting plate 21, a lower connecting plate 22, a large waist plate 23 and a small waist plate 24, and the upper connecting plate 21 and the lower connecting plate 22 are all ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com