Environment-friendly drying device for aggregate sand-making process

A drying device and process technology, which is applied in the field of environmental protection drying devices for aggregate sand making process, can solve the problems of uneven drying, single drying form, and serious agglomeration, so as to increase the discharge speed and ensure Uniformity, the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

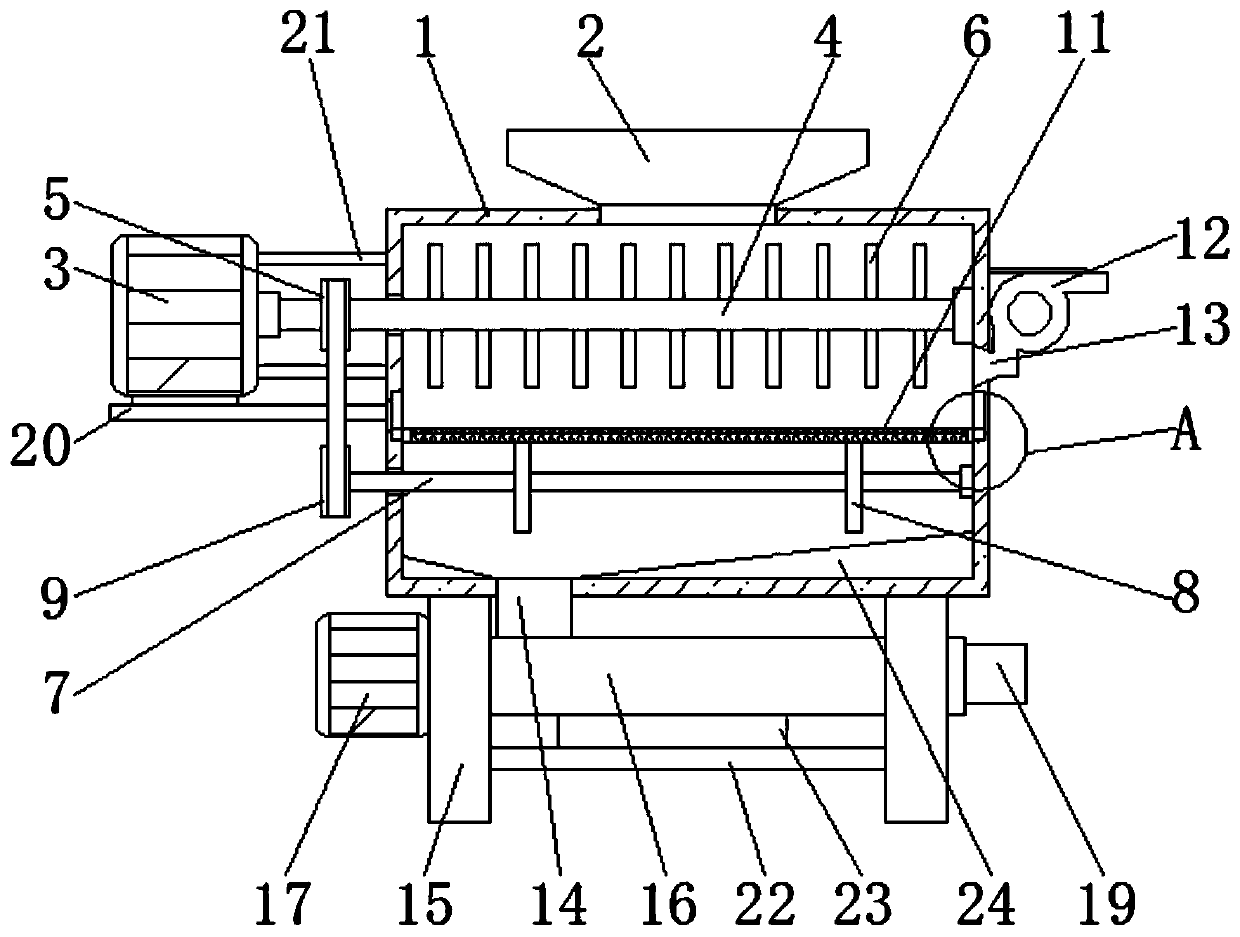

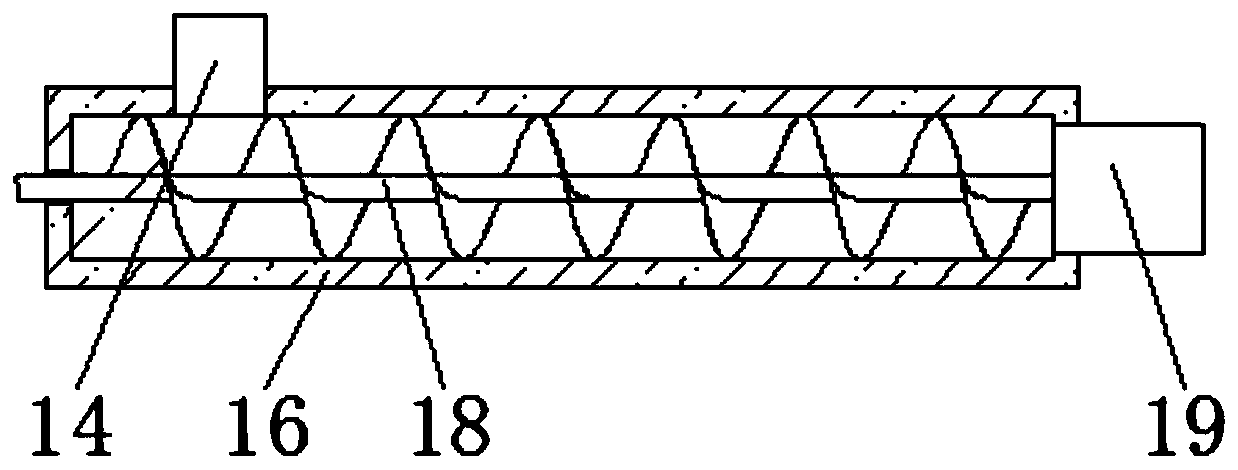

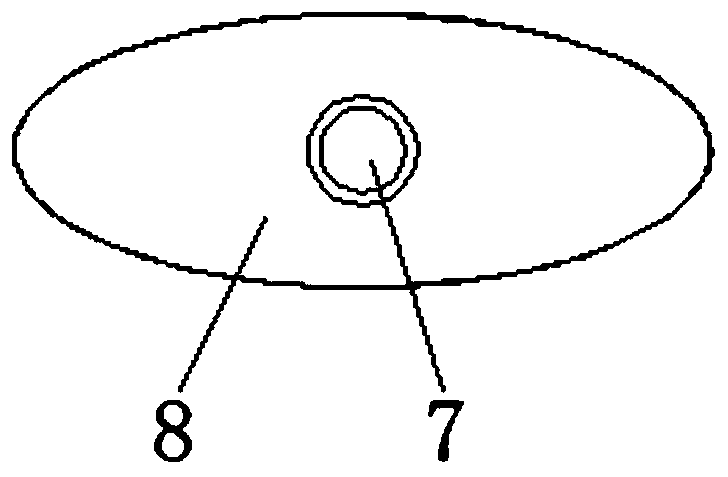

[0025] see Figure 1-4 , the present invention provides the following technical solutions: an environmentally friendly drying device for aggregate sand making process, including a box body 1, the top of the box body 1 is connected with a feed hopper 2, and the left side of the box body 1 is fixedly connected with a first motor 3. The output end of the first motor 3 is fixedly connected to the stirring shaft 4, the left side of the surface of the stirring shaft 4 is fixedly connected to the driving wheel 5, and the right side of the stirring shaft 4 runs through the outside of the box 1 and extends to the bottom of the box 1. In the inner cavity, the right side of the stirring shaft 4 is movably connected with the right side of the inner cavity of the box body 1 through a bearing, the surface of the stirring shaft 4 is fixedly connected with the stirring rod 6, and the right side of the inner cavity of the box body 1 is movably connected with a rotating rod through a bearing 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com