Greek fermented yoghurt and preparation method thereof

A yogurt and fermentation-based technology, applied in the field of Greek fermented yogurt and its preparation, can solve problems such as poor flavor and taste, and achieve the effects of enhancing product texture, better taste and flavor, and smooth and uniform taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

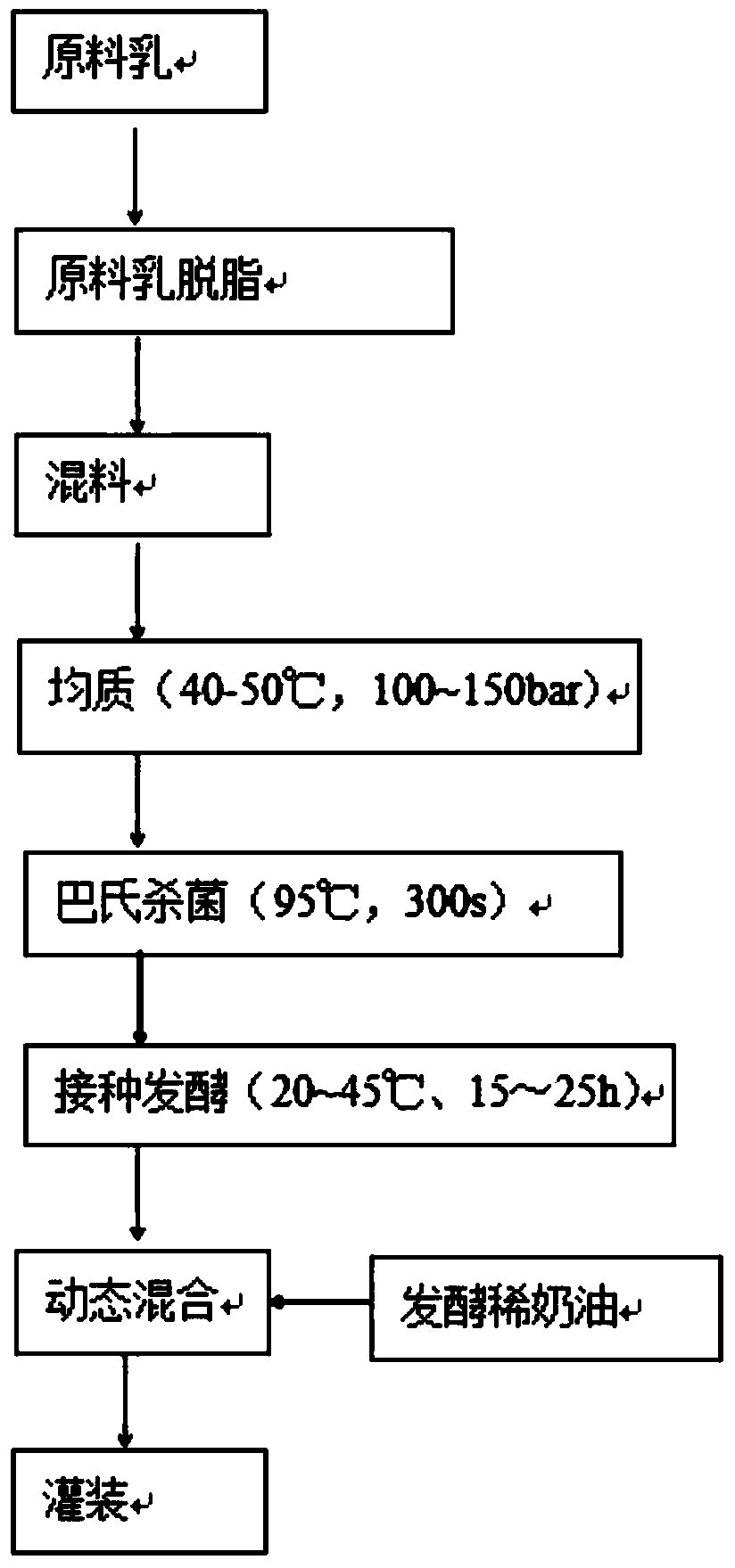

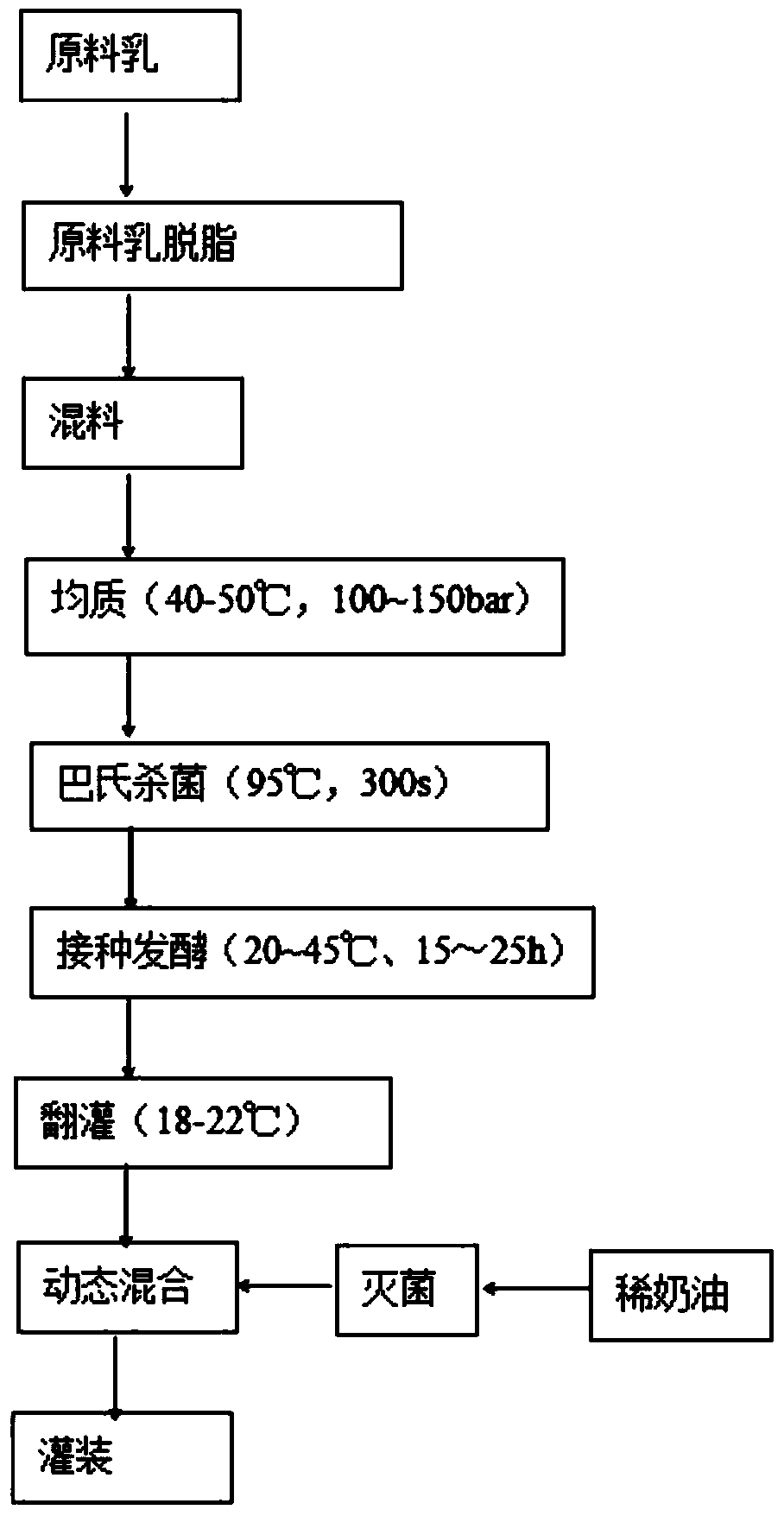

[0049] The invention relates to Greek fermented yoghurt, which is prepared by adding fermented cream to a skimmed raw milk fermentation base material through an online adding method, and then mixing it uniformly.

Embodiment 2

[0051]The invention relates to Greek fermented yoghurt, which is prepared by adding fermented cream to a skimmed raw milk fermentation base material through an online adding method, and then mixing it uniformly. Its specific preparation method is as follows:

[0052] (1) Preparation of skimmed raw milk fermentation base material:

[0053] The skimmed raw milk fermentation base material is specifically prepared from raw materials including 92% fresh milk, 5.5% white sugar, 0.5% Lactobacillus bulgaricus, and 0.5% Streptococcus thermophilus through the following steps:

[0054] A. Raw milk skim

[0055] Using a centrifuge to skim the fresh milk so that the fat content of the skimmed raw milk is 0.05%;

[0056] B. Mixing

[0057] Mix the skim milk obtained in step A, add 5.5% white granulated sugar in a shear tank and stir for 10 minutes;

[0058] C. Homogeneous

[0059] The material obtained in step B is homogenized under the condition of 150bar, and the homogenization tempe...

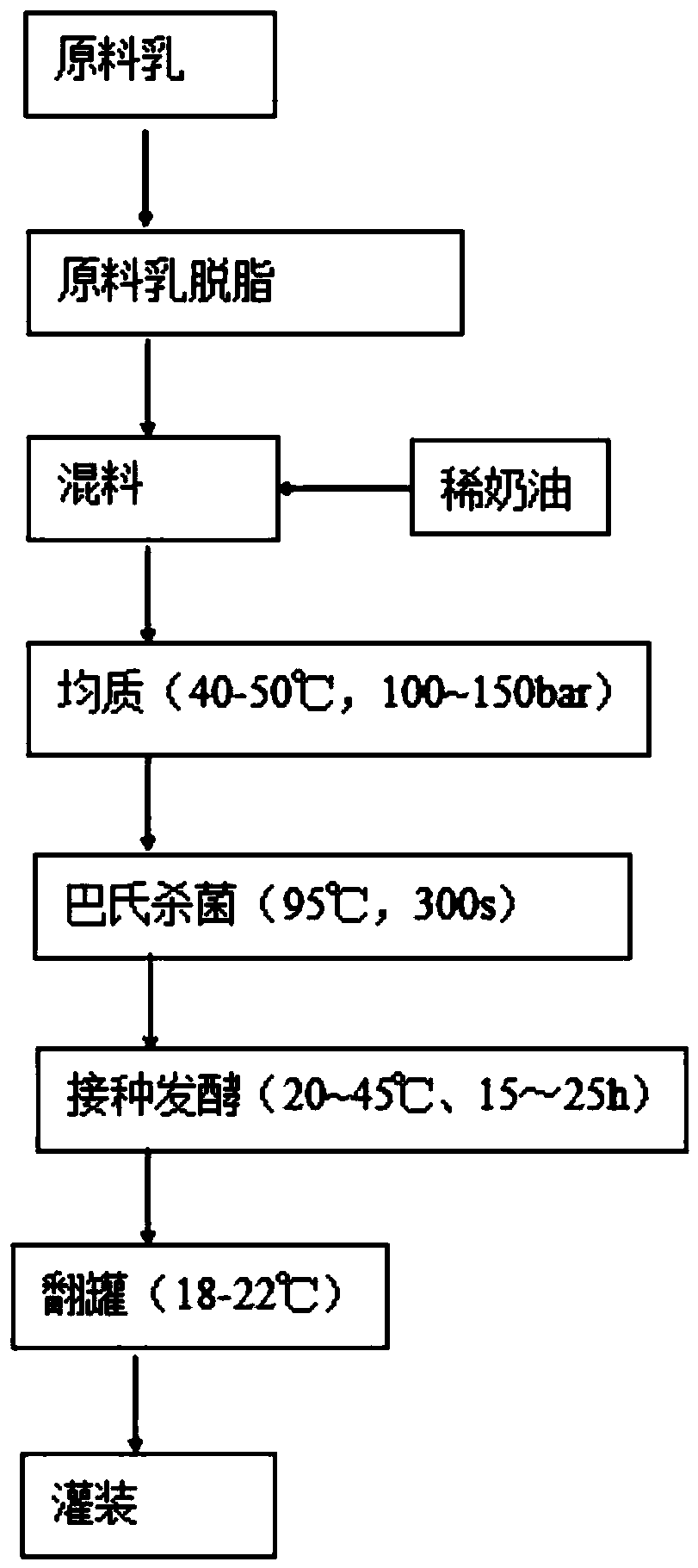

Embodiment 3

[0073] The invention relates to Greek fermented yoghurt, which is prepared by adding fermented cream to a skimmed raw milk fermentation base material through an online adding method, and then mixing it uniformly. Its specific preparation method is as follows:

[0074] (2) Preparation of skimmed raw milk fermentation base material:

[0075] The skimmed raw milk fermentation base material is specifically prepared from raw materials including 89% fresh milk, 6% white sugar, 0.3% Lactobacillus bulgaricus, and 0.3% Streptococcus thermophilus through the following steps:

[0076] A. Raw milk skim

[0077] Using a centrifuge to skim the fresh milk so that the fat content of the skimmed milk is 0.05%;

[0078] B. Mixing

[0079] Mix the skim milk obtained in step A, add 6% white sugar in a shear tank and stir for 8 minutes;

[0080] C. Homogeneous

[0081] The material obtained in step B is homogenized under the condition of 120bar, and the homogenization temperature is 45°C;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com