Preparation process of titanium and titanium alloy thick plate

A preparation process and titanium alloy technology, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as production limitations of titanium and titanium alloy thick plates, and achieve the effect of good plate shape and high thickness precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

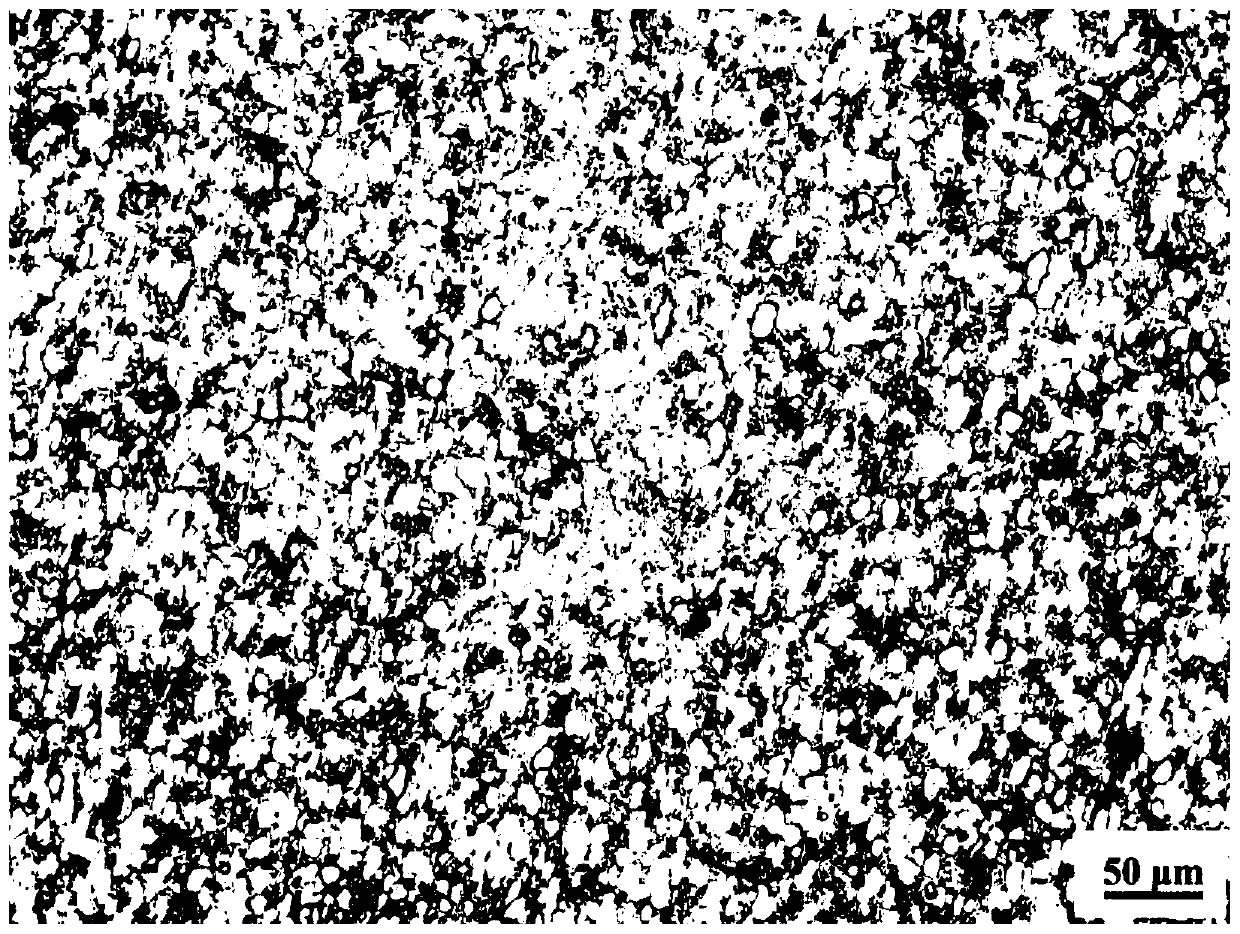

Image

Examples

Embodiment 1

[0040] This example provides a preparation process for titanium and titanium alloy thick plates, the steps include:

[0041] S1: Insulate the slab;

[0042] S2: removing the oxide layer on the surface of the slab after the treatment in step S1;

[0043] S3: rolling the slab processed in step S2 to the target width for the first time;

[0044] S4: Reversing the direction of the slab processed in step S3 and then rolling it to the target thickness for the second time;

[0045] S5: Straightening the slab processed in step S4.

[0046] Among them, the raw material slab thickness of the titanium and titanium alloy thick plate is 350-500 mm.

[0047] The thickness of titanium and titanium alloy thick plates is 50-200mm.

[0048] The width of titanium and titanium alloy thick plates is 1400-3000mm.

[0049] The temperature of the heat preservation treatment is 10 to 20° C. below the phase transition temperature.

[0050] The heat preservation treatment time is 14-20 hours.

[...

Embodiment 2

[0063] In this example, a thick TC4 alloy plate with a width of 1800 mm and a thickness of 60 mm was actually rolled. The specific process is:

[0064] S1: Insulate the slab;

[0065] S2: removing the oxide layer on the surface of the slab after the treatment in step S1;

[0066] S3: rolling the slab processed in step S2 to the target width for the first time;

[0067] S4: Reversing the direction of the slab processed in step S3 and then rolling it to the target thickness for the second time;

[0068] S5: Straightening the slab processed in step S4.

[0069] Among them, the raw material slabs of titanium and titanium alloy thick plates have a thickness of 360mm and a width of 1200mm.

[0070] In step S1, the temperature of the heat preservation treatment is 10-20°C below the phase transition temperature, and the phase transition point of TC4 is 990°C, so the heat preservation temperature should be 970°C. The time of heat preservation treatment is 15h.

[0071] In step S4...

Embodiment 3

[0074] In this example, a thick pure titanium plate with a width of 2000 mm and a thickness of 160 mm was actually rolled. The specific process is:

[0075] S1: Insulate the slab;

[0076] S2: removing the oxide layer on the surface of the slab after the treatment in step S1;

[0077] S3: rolling the slab processed in step S2 to the target width for the first time;

[0078] S4: Reversing the direction of the slab processed in step S3 and then rolling it to the target thickness for the second time;

[0079] S5: Straightening the slab processed in step S4.

[0080] Among them, the raw material slab thickness of titanium and titanium alloy thick plate is 480mm.

[0081] The temperature of heat preservation treatment is 10-20°C below the phase transition temperature, and the heat preservation temperature of pure titanium is 900°C. The time of heat preservation treatment is 18h.

[0082] In step S3, the first rolling is carried out until the width is rolled from 1200mm to 180...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com