Clothes treatment device and control method thereof

A technology of a clothes treatment device and a control method, which is applied to washing devices, household clothes dryers, textiles and papermaking, etc., and can solve problems such as inability to adapt to operating modes, low condensation efficiency, and influence on drying effect, and achieve the best condensation effect , Improve the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

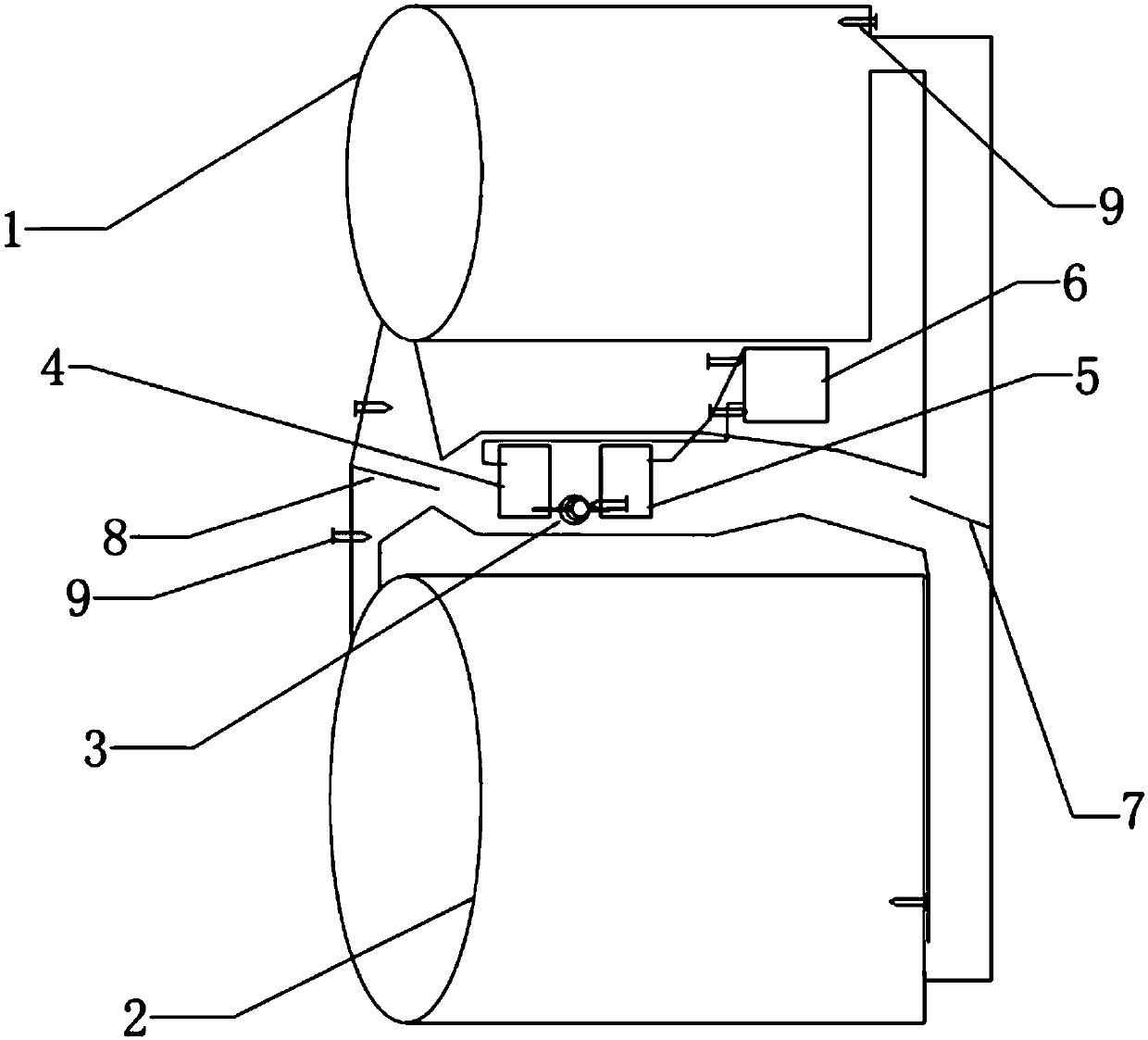

[0035] A clothes treating device, such as figure 2 As shown, it includes a heat pump system, a plurality of clothes drying areas and an air duct 3 that provides hot air to the drying areas. The heat pump system includes an evaporator 4, a compressor 6, a condenser 5 and a throttling system. The heat exchange medium is in the The evaporator 4, the compressor 6, the condenser 5 and the throttling system are sequentially connected to form a circulating loop to heat the air flowing through the air duct 3. A controllable on-off branch channel, each branch channel is equipped with a different throttling device.

[0036] As an embodiment of the present invention, a plurality of clothes drying areas share the same air duct 3, and the air outlet of the air duct 3 is provided with openings respectively communicating with the air inlets of the plurality of clothes drying areas, and the openings are provided with controllable Opening air distribution valve;

[0037] The air inlet of th...

Embodiment approach

[0049] As an embodiment of the present invention, the drying condition is: when the temperature of the air outlet of the drying zone and the temperature between the evaporator 4 and the condenser 5 is greater than a set value, the drying is determined.

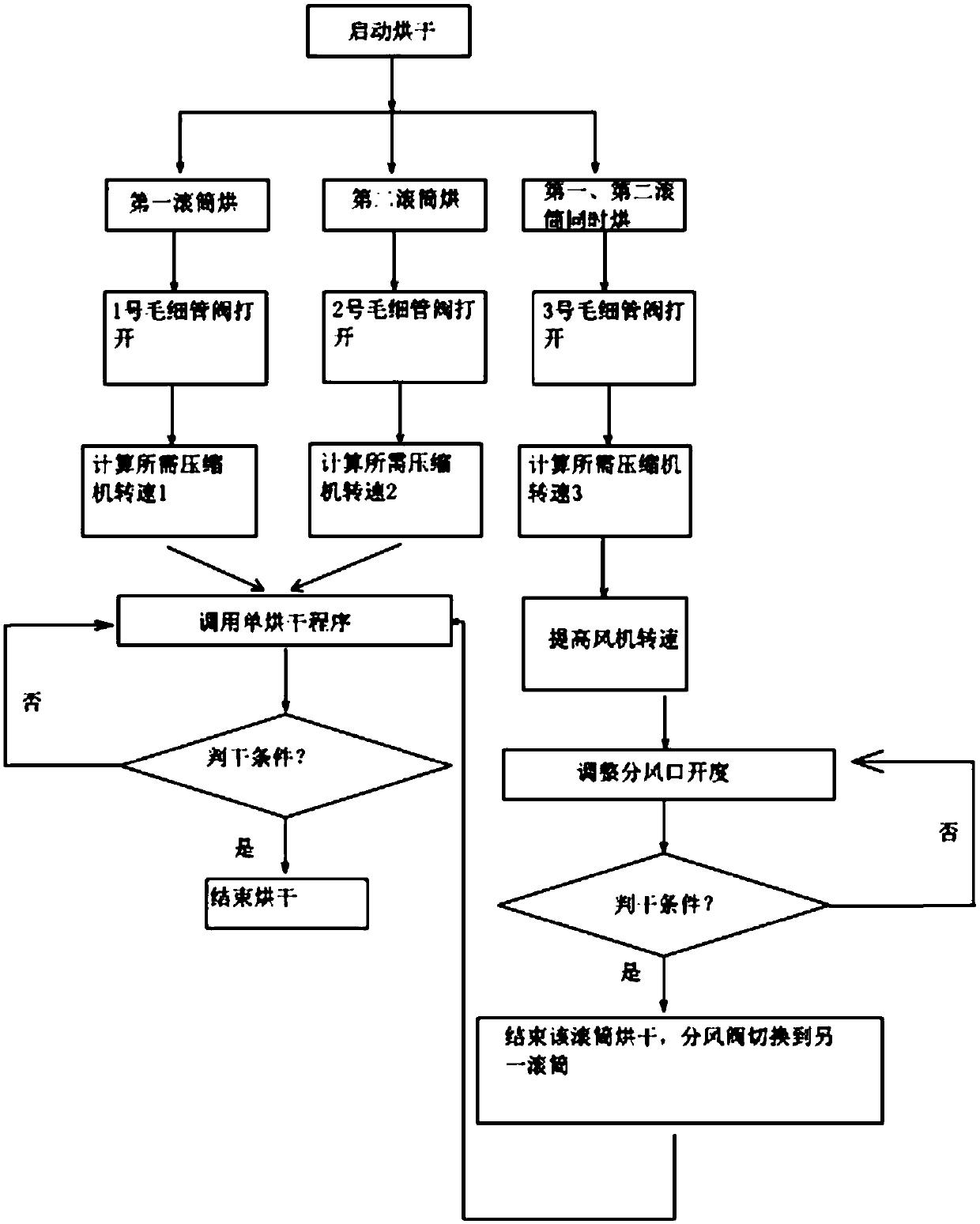

[0050] As an embodiment of the present invention, the clothes treatment device includes a first drying zone 1 and a second drying zone 2, and the throttling system includes a first channel, a second channel and a third channel respectively provided with capillary tubes, and the optional The first drying zone 1 / second drying zone 2 are dried separately or the first drying zone 1 and the second drying zone 2 are dried at the same time. corresponding to the drying area, and adjust the speed or / and required air volume of the compressor 6 according to the weighing value of the operating load;

[0051] As an embodiment of the present invention, the laundry processing device is preset with a database of the rotational speed of the co...

Embodiment 2

[0055] This embodiment is a further limitation or optimization of Embodiment 1.

[0056] The clothes processing device includes an outer cylinder, an air duct 3 and an inner cylinder arranged in the outer cylinder, the air inlet and the air outlet of the air duct 3 are respectively connected to the rear and front of the outer cylinder, and the air duct 3 and the outer cylinder form a A closed circuit, the air duct 3 is provided with a fan, the evaporator 4 is located at the air inlet of the air duct 3, and is used to condense the air flowing through the air duct 3, and the condenser 5 is located between the fan and the evaporator 4. In channel 3, it is used to heat the air flowing through the air channel 3.

[0057] The laundry treatment device of the present invention includes a first drying zone 1 and a second drying zone 2, and the throttling system includes a first channel, a second channel and a first channel connected in parallel between the evaporator 4 and the condense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com