Production method of integral woven dipped canvas

A technology of dipping canvas and production method, which is applied in textiles, papermaking, textiles, fabrics, etc., can solve the problems of low rubber adhesion, low strength and high production cost, so as to improve peeling resistance and service performance, Improve the effect of the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 discloses a kind of production method of overall weaving dipped canvas, comprises following preparation steps:

[0024] Step 1, preparation of base cloth

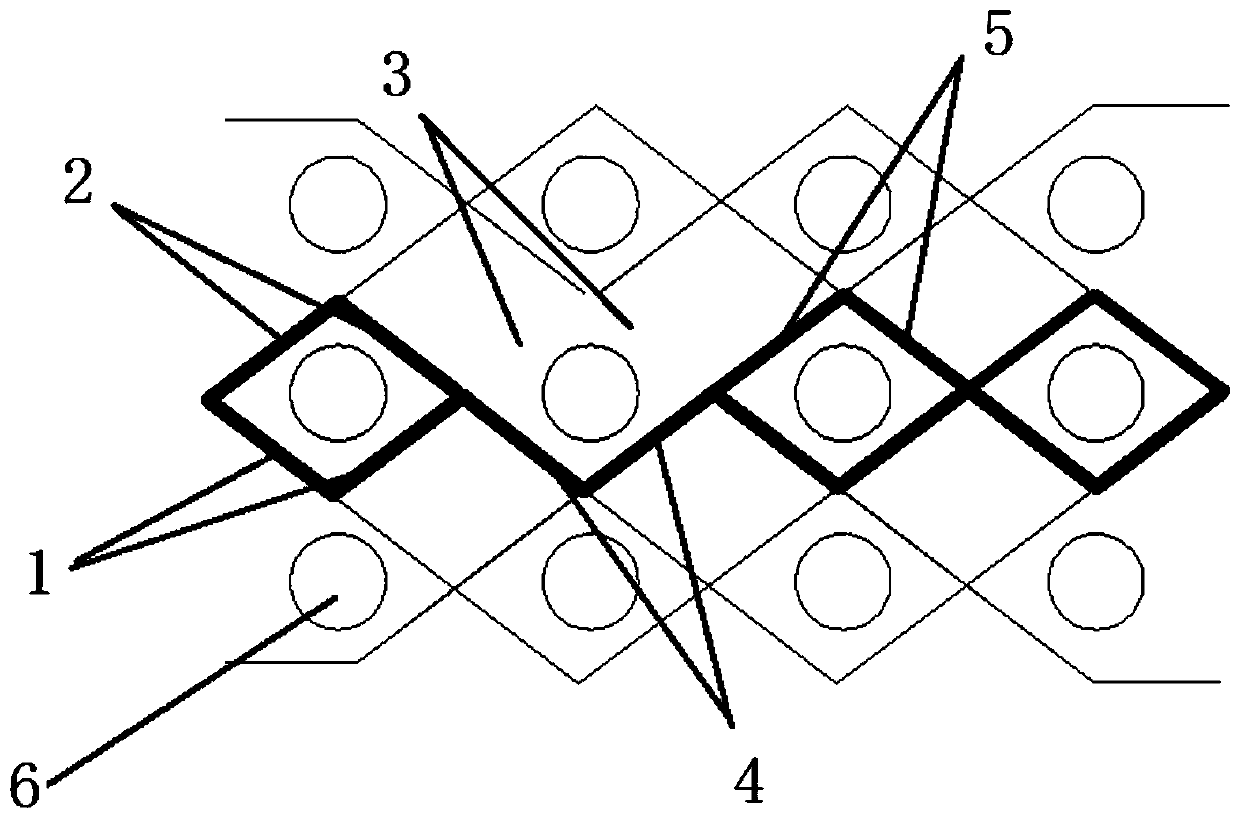

[0025] Use polyester industrial yarn as the warp and nylon industrial yarn as the weft, and weave the warp and weft using the method of integral weaving; figure 1 As shown, there are 8 warp threads (shown in 1-5), and 6 weft threads are divided into 4 rows, which are woven by double layers, and woven into a base fabric for use; the warp thread density is 150 threads / 10cm, and the weft thread density is 80 threads / 10cm; warp is 800D, weft is 500D. The twist of polyester industrial yarn is 20 twists / 10cm, and the twist of nylon industrial yarn is 10 twists / 10cm.

[0026] Step 2, preparation of dipping solution

[0027] The dipping solution includes a primary dipping solution and a secondary dipping solution, wherein the primary dipping solution is composed of resorcinol, formaldehyde, primary latex and...

Embodiment 2

[0031] Embodiment 2 discloses a kind of production method of overall weaving dipped canvas, comprises following preparation steps:

[0032] Step 1, preparation of base cloth

[0033] Use polyester industrial yarn as the warp and nylon industrial yarn as the weft, and weave the warp and weft using the method of integral weaving; among them, there are 8 warp yarns (shown in 1-5), and 6 weft yarns are divided into 4 rows, and weaving is done in double layers. Formed, woven into a base cloth, and set aside; the warp density is 180 threads / 10cm, and the weft thread density is 100 threads / 10cm; the warp thread is 1000D, and the weft thread is 700D. The twist of polyester industrial yarn is 40 twists / 10cm, and the twist of nylon industrial yarn is 30 twists / 10cm.

[0034] Step 2, preparation of dipping solution

[0035] The dipping solution includes a primary dipping solution and a secondary dipping solution, wherein the primary dipping solution is composed of resorcinol, formaldeh...

Embodiment 3

[0039] Embodiment 3 discloses a kind of production method of overall weaving dipped canvas, comprises following preparation steps:

[0040] Step 1, preparation of base cloth

[0041] Use polyester industrial yarn as the warp and nylon industrial yarn as the weft, and weave the warp and weft using the method of integral weaving; figure 1 As shown, there are 8 warp threads (shown in 1-5), and 6 weft threads are divided into 4 rows, which are woven with double layers and woven into a base fabric for use; the warp thread density is 220 threads / 10cm, and the weft thread density is 110 threads / 10cm; the warp is 1500D, and the weft is 1000D. The twist of polyester industrial yarn is 60 twists / 10cm, and the twist of nylon industrial yarn is 60 twists / 10cm.

[0042] Step 2, preparation of dipping solution

[0043] The dipping solution includes a primary dipping solution and a secondary dipping solution, wherein the primary dipping solution is composed of resorcinol, formaldehyde, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com