A split brake and motor

A brake and split technology, applied in the direction of brake type, axial brake, brake actuator, etc., can solve the problems affecting the reliability of the encoder 3, abnormal communication, etc., and achieve the effect of simple and reliable process and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The split brake of the first embodiment is installed on the non-shaft extension end of the motor, and the encoder 3 is installed on the end of the split brake of the first embodiment away from the motor.

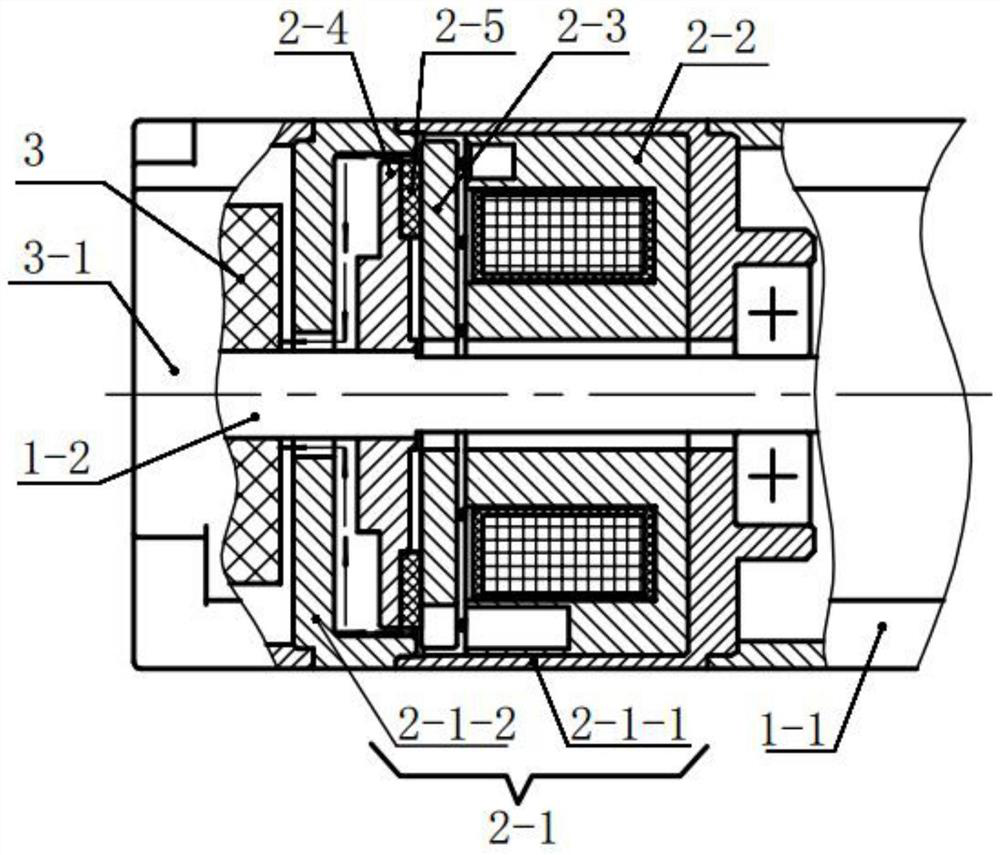

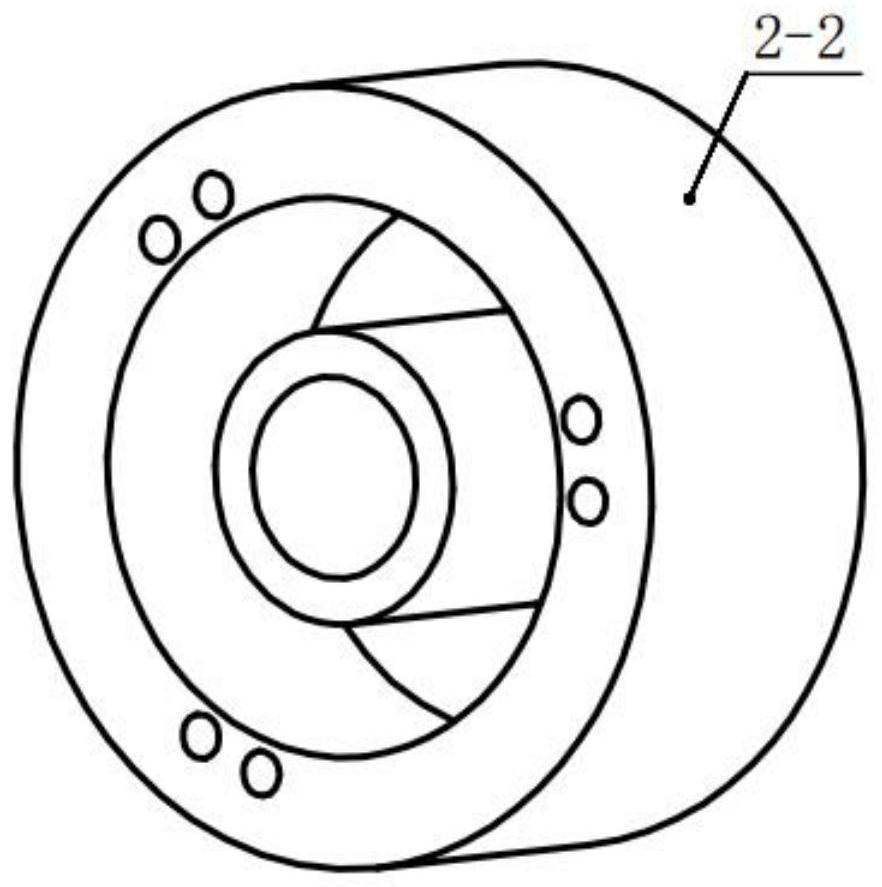

[0038] A split type brake of the first embodiment, such as image 3 As shown, it includes a housing 2-1 of the brake, a brake iron core 2-2, an armature 2-3, a wheel hub 2-4, and a friction plate 2-5.

[0039] The housing 2-1 of the brake includes a first end cover 2-1-1 and a second end cover 2-1-2, and the first end cover 2-1-1 and the second end cover 2-1-2 are fixed by screws . The first end cover 2-1-1 is fixed with the housing 1-1 of the motor by screws, and the second end cover 2-1-2 is in clearance fit with the rotating shaft 1-2 of the motor.

[0040] The brake iron core 2-2, the armature 2-3, the wheel hub 2-4 and the friction plate 2-5 are all arranged in the first end cover 2-1-1.

[0041] The brake iron core 2-2 is tightly fitted with the first end cov...

Embodiment 2

[0047] The split brake of the second embodiment is installed on the non-shaft extension end of the motor, and the encoder 3 is installed on the end of the split brake of the second embodiment away from the motor.

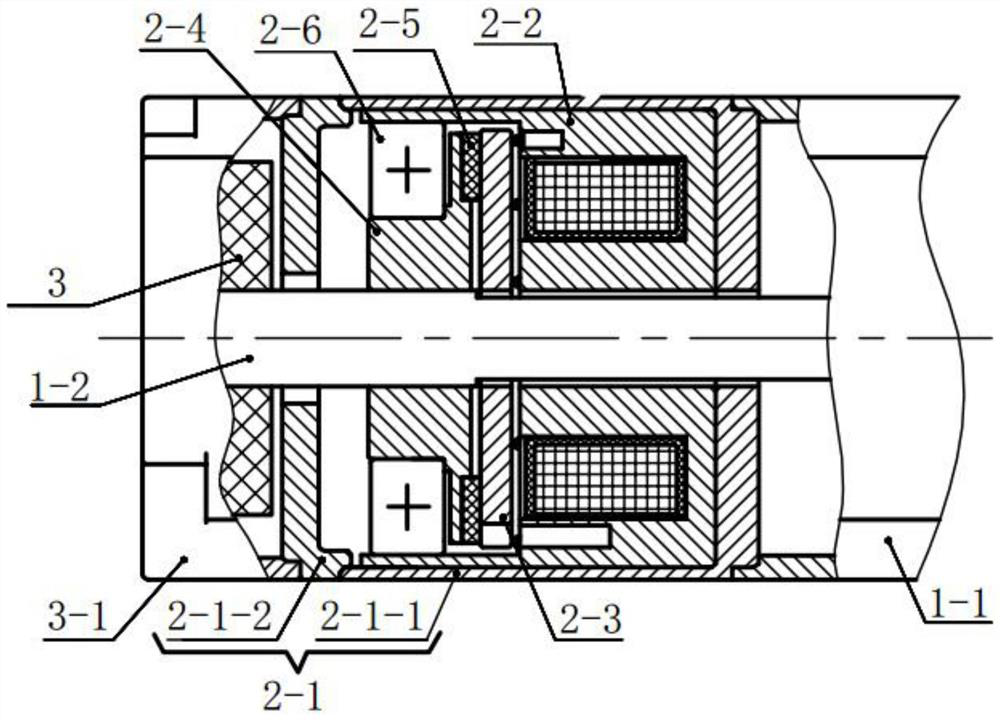

[0048] A split type brake of the second embodiment, such as Figure 5 As shown, it includes a housing 2-1 of the brake, a brake iron core 2-2, an armature 2-3, a wheel hub 2-4, and a friction plate 2-5.

[0049] The housing 2-1 of the brake includes a first end cover 2-1-1 and a second end cover 2-1-2, and the first end cover 2-1-1 and the second end cover 2-1-2 are fixed by screws . The first end cover 2-1-1 is fixed with the housing 1-1 of the motor by screws, and the second end cover 2-1-2 is in clearance fit with the rotating shaft 1-2 of the motor.

[0050] The brake iron core 2-2, the armature 2-3, the wheel hub 2-4 and the friction plate 2-5 are all arranged in the first end cover 2-1-1.

[0051] The brake iron core 2-2 is tightly fitted with the first end...

Embodiment 3

[0055] A motor includes a brake, and the brake is the aforementioned split type brake. The brake can improve the reliability of the encoder 3 during operation, so that the encoder 3 can accurately measure the parameters of the motor during operation, thereby improving the reliability of the motor operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com